Flexible power generation thin-film and preparation method thereof

A technology of power generation film and conductive film, which is applied in the direction of friction generator, cable/conductor manufacturing, circuit, etc., can solve application problems, achieve the effect of realizing film thickness, improving conductivity, and realizing precise control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

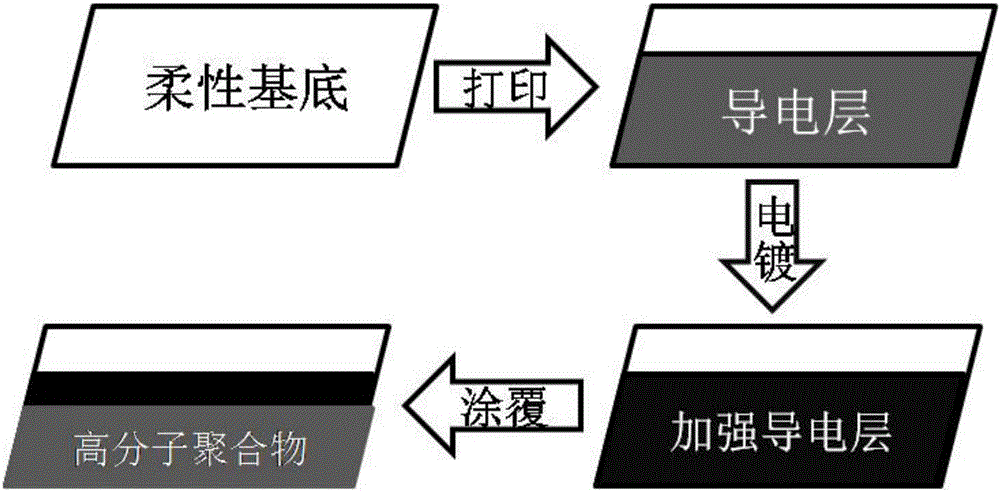

[0026] A flexible power generation film, which includes a non-conductive paper flexible substrate, a nano-silver conductive film printed on the paper flexible substrate, a copper film deposited on the nano-silver conductive film by electroplating, and a polydimethylsiloxane coated on the copper film Silicone layer.

[0027] The method for preparing the flexible power generation film comprises the following steps:

[0028] 1) Using inkjet printing technology to print a layer of nano-silver conductive film on the paper flexible substrate;

[0029] 2) Electroplating and depositing a layer of copper film on the nano-silver conductive film, the electroplating deposition is electroplating with 0.1mol / L copper ions, the electroplating voltage is 1.5V, and the time is 15min;

[0030] 3) Spray a layer of polydimethylsiloxane on the copper film;

[0031] 4) After the polydimethylsiloxane layer is dried, a flexible power generation film can be obtained.

[0032] In addition, another f...

Embodiment 2

[0040] A flexible power generation film, which includes a non-conductive foam flexible substrate, a nano-silver conductive film printed on the foam flexible substrate, a nickel film deposited on the nano-silver conductive film by electroplating, and a polydimethylsiloxane coated on the nickel film Silicone layer.

[0041] The method for preparing the flexible power generation film comprises the following steps:

[0042] 1) Using inkjet printing technology to print a layer of nano-silver conductive film on the foam flexible substrate;

[0043] 2) Electroplating and depositing a layer of nickel film on the nano-silver conductive film, the electroplating deposition uses 0.2mol / L nickel ions for electroplating, the electroplating voltage is 1V, and the time is 30min;

[0044] 3) Dip-coat a layer of polydimethylsiloxane on the nickel film;

[0045] 4) After the polydimethylsiloxane layer is dried, a flexible power generation film can be obtained.

[0046] In addition, another fl...

Embodiment 3

[0054] A flexible power generation film, which includes a non-conductive paper flexible substrate, a graphene conductive film printed on the paper flexible substrate, a copper-nickel alloy film deposited on the graphene conductive film by electroplating, and a polymer coated on the copper-nickel alloy film. Dimethicone layer.

[0055] The method for preparing the flexible power generation film comprises the following steps:

[0056] 1) Using inkjet printing technology to print a layer of graphene conductive film on the paper flexible substrate;

[0057] 2) Electroplating and depositing a layer of copper-nickel alloy film on the graphene conductive film, the electroplating deposition uses 0.05mol / L copper-nickel ions for electroplating, the electroplating voltage is 1V, and the time is 1h;

[0058] 3) Deposit a polydimethylsiloxane layer on the copper-nickel alloy film and nickel alloy film by initiating chemical vapor deposition;

[0059] 4) After the polydimethylsiloxane la...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com