Metal-coated resin particles and electroconductive adhesive in which same are used

A technology of resin particles and metal covering layers, applied in conductive adhesives, conductive connections, adhesives, etc., can solve the problems of reduced adhesion between resin particles and metals, inability to obtain reliable electrical connections, etc., to achieve excellent electrical connection, The effect of improving the reliability of the connection

Active Publication Date: 2016-12-14

TATSUTA ELECTRICWIRE & CABLE

View PDF15 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0010] However, even with these metal-coated resin particles, as the compression deformation is repeated, the adhesion between the resin particles and the metal decreases, and when used in a conductive adhesive, a highly reliable electrical connection cannot be obtained.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment

[0052] Examples of the present invention are shown below, but the present invention is not limited to the following examples. In addition, unless otherwise specified, the following compounding ratio etc. are mass standards.

[0053] 1. Adjustment and evaluation of metal-coated resin particles

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Login to View More

Abstract

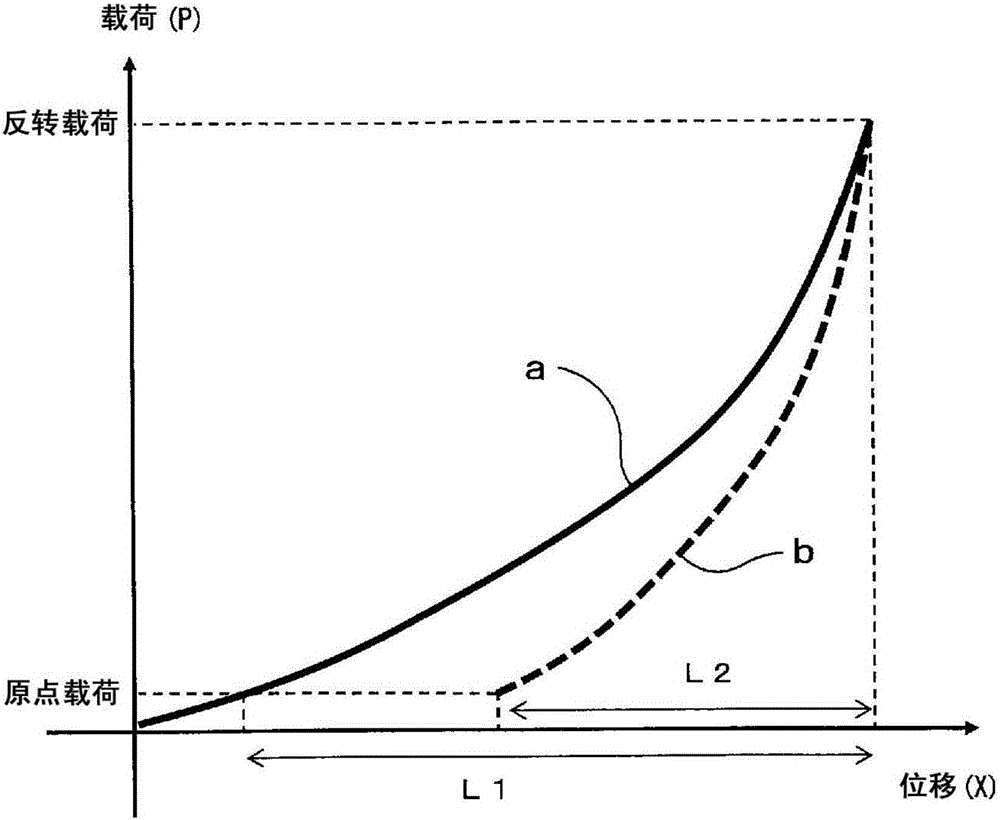

Provided are metal-coated resin particles that comprise resin particles and a metal coating layer that covers at least some of the resin particles, wherein it is possible to obtain a high-reliability electrical connection after repeated compression. There are used metal-coated resin particles that have an average grain diameter of 1-100[mu]m and exhibit a recovery of at least 90% after 30% compressive deformation, the metal coating layer comprising a metal having a Vickers hardness of 100 or less and an average thickness of 20-150 nm.

Description

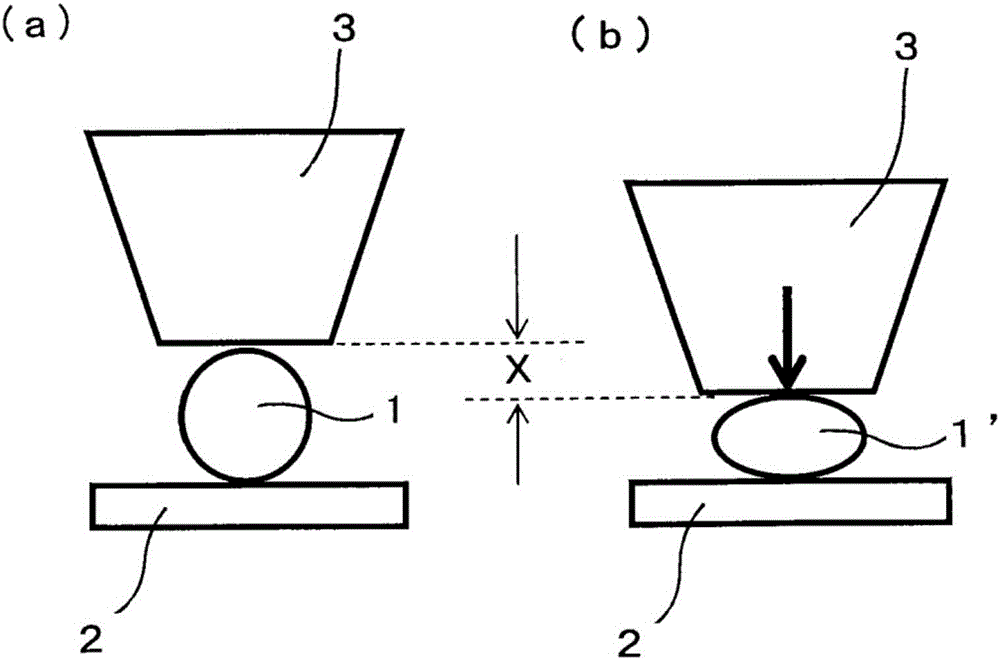

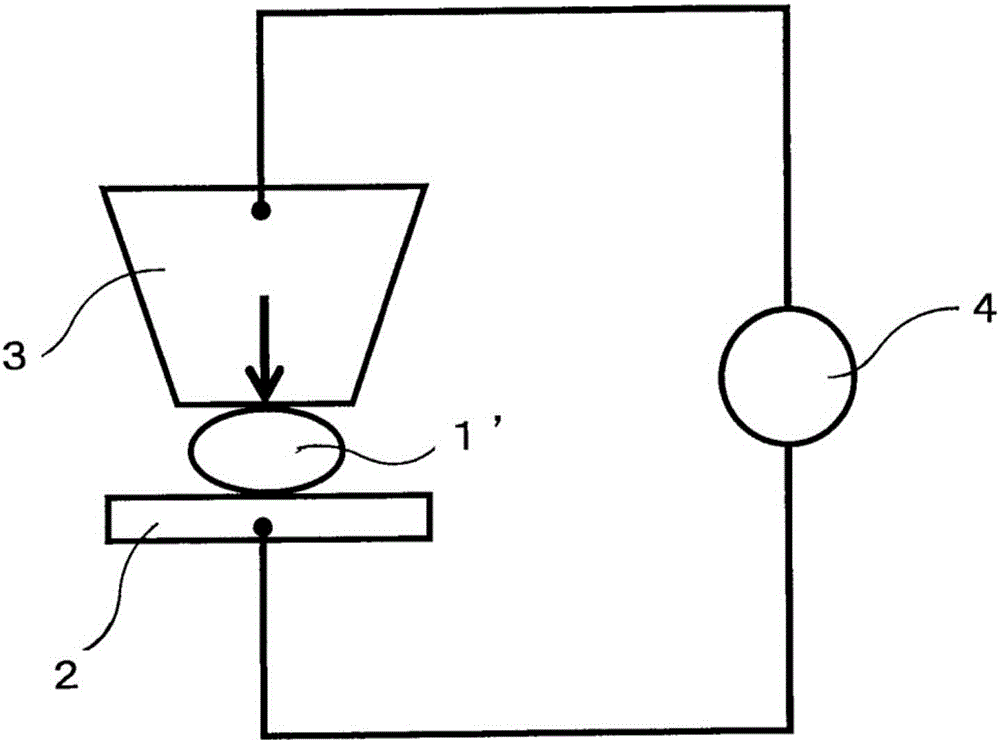

technical field [0001] The present invention relates to metal-coated resin particles and a conductive adhesive using the same. Background technique [0002] As metal-coated resin particles compounded in conductive adhesives used for electrode connection of printed circuit boards, metal-coated resin particles in which resin particles containing acrylic resin are coated with precious metals such as gold via a nickel layer are often used. . [0003] For example, Patent Document 1 discloses that the K value at 10% compression deformation is 50 to 250 kgf / mm for the purpose of providing conductive microspheres having moderate compression deformation and deformation recovery, and excellent connection reliability. 2 The electroconductive microparticles|fine-particles which provided the electroconductive layer which consists of a nickel-gold plating layer on the surface of a microsphere with a recovery rate of 15-100% of high elastic modulus. [0004] In addition, Patent Document ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): H01B5/00C09J9/02C09J11/08C09J201/00H01B1/00H01B1/16H01B1/22H01B5/16H01R11/01

CPCC09J9/02C09J11/08C09J201/00H01B1/00H01B1/16H01B1/22H01B5/00H01B5/16H01R11/01

Inventor 十代田优美登峠雅之寺田恒彦堀内伸中尾幸道

Owner TATSUTA ELECTRICWIRE & CABLE

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com