Reaction kettle for separation and recovery treatments of fluorine-containing material by adopting reduced pressure distillation process

A separation and recovery, reaction kettle technology, applied in the method of using atmospheric pressure to chemically change substances, processes below atmospheric pressure, chemical/physical/physical-chemical stationary reactors, etc. Negative pressure resistance, corrosion resistance and other problems, to achieve the effect of promoting stability and improving safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

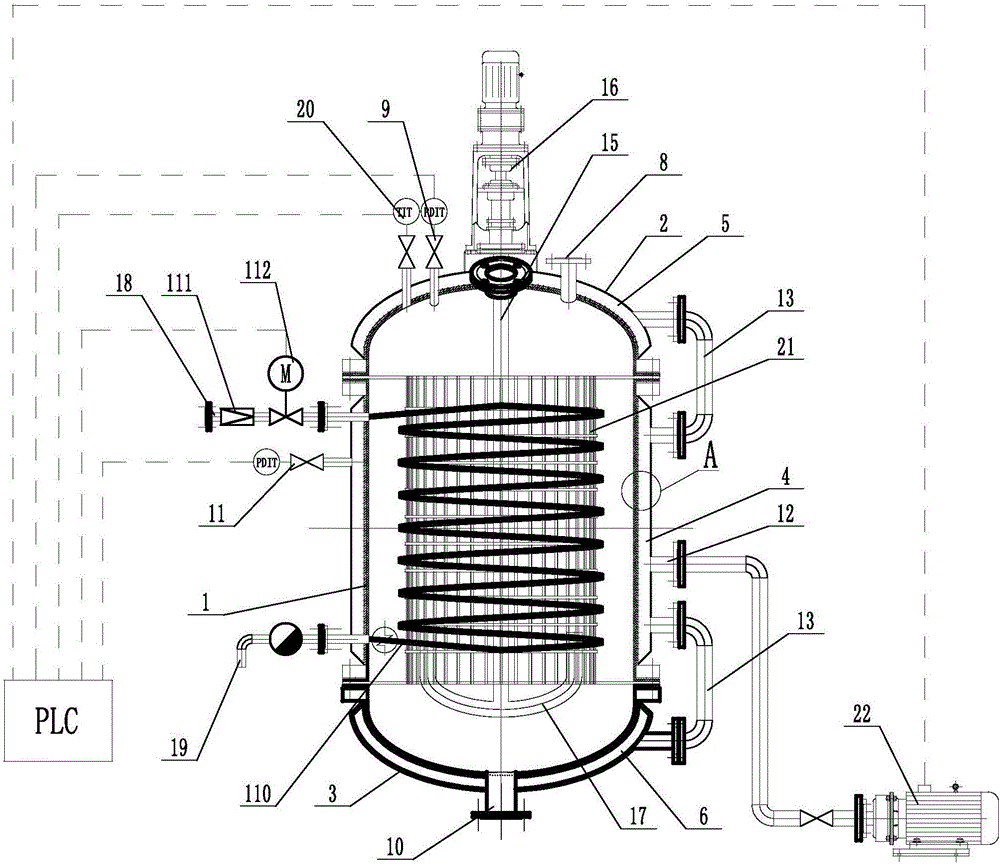

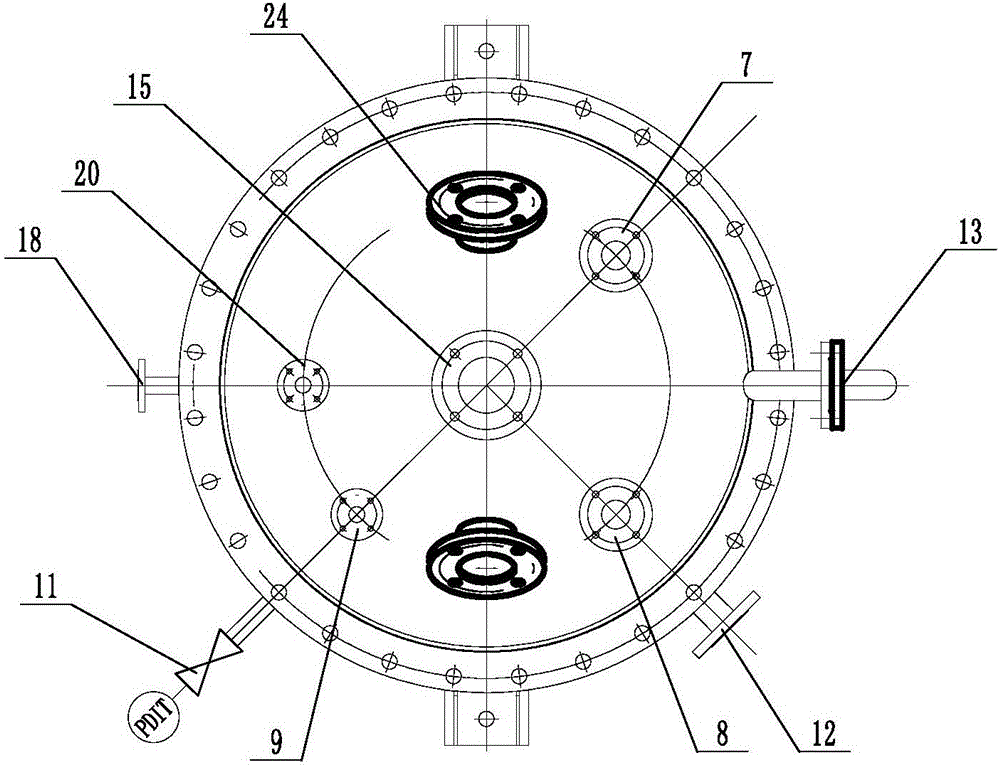

[0023] The specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

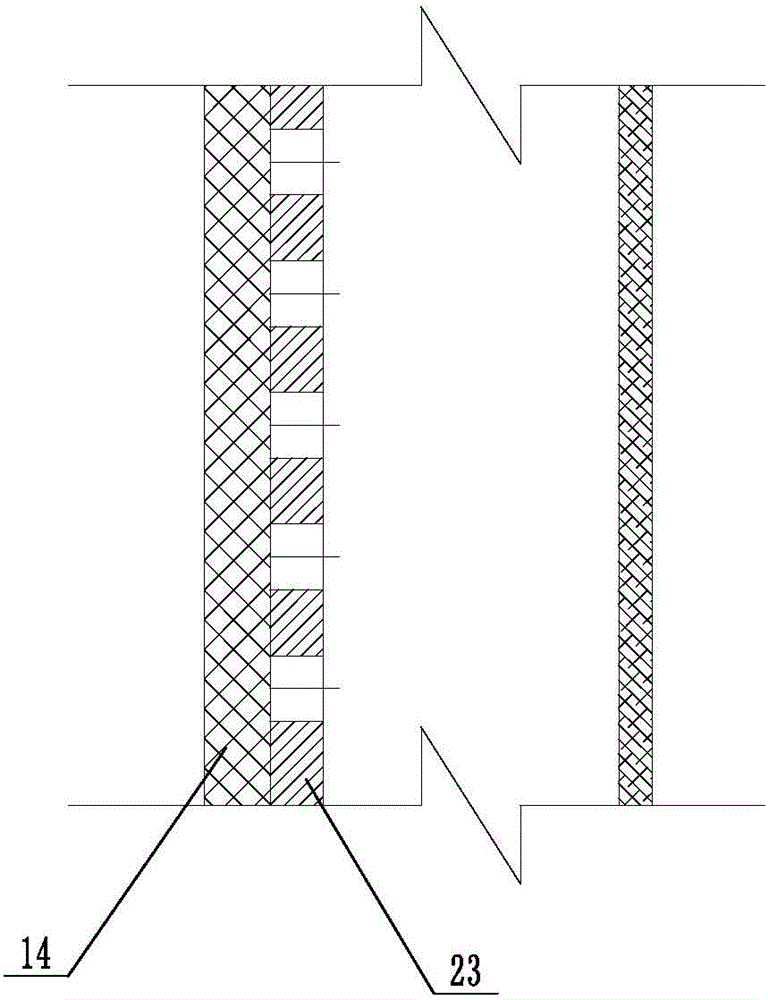

[0024] Such as figure 1 As shown, in this embodiment, the vacuum distillation process is used to dispose of the reaction kettle for separating and recovering fluorine-containing materials. The reaction kettle can withstand the distillation reaction under the condition of absolute vacuum and a temperature of 150 degrees. This reactor can resist the corrosion of fluorine-containing wastewater, fluorine-containing strong acid, and fluorine-containing mixed acid. It includes the kettle body 1 and the upper head 2 and the lower head 3 fixedly connected to the upper and lower ends of the kettle body 1, wherein the upper head 2, the lower head 3 and the kettle body 1 are fixedly connected by a large flange. The kettle body 1 is provided with a stirring shaft 15, and the upper end of the stirring shaft 15 protrudes from the upper head 2 and is conn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com