Spraying production device for single detergent piece

A technology for production equipment and laundry tablets, applied in the direction of spraying equipment, etc., can solve the problems of low automation and work efficiency, low spraying production efficiency, high manual labor intensity, etc., to achieve reduced labor intensity, high automation, simple and compact structure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

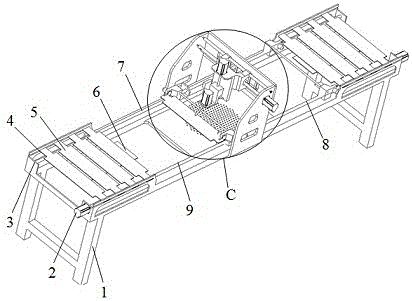

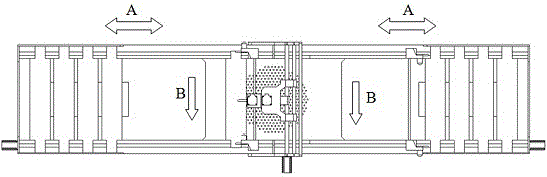

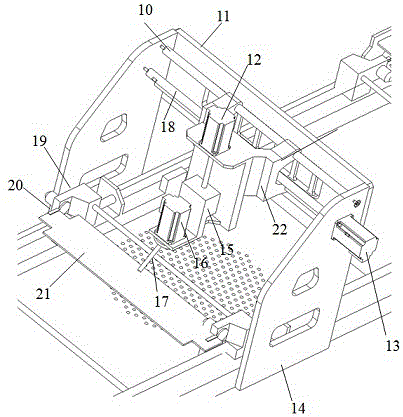

[0017] control Figure 1 to Figure 3 At the beginning of work, under the action of the driving motor 2, the laundry piece moving slider 19 moves closer to the transmission bracket 1 and moves to the limit position to stop. The nozzle translation motor 13 drives the bracket 22 to move to one side of the transmission bracket 1 (close to the side plate ), the nozzle vertical movement motor 12 moves the nozzle 17 up to the highest position, and the operator places the laundry sheet film 5 on the upper side of the pallet 6, and the device is ready to complete the preparation work at this time.

[0018] After the device is started, the drive motor 2 drives the left side drive screw 9 to rotate, and the laundry sheet moving slider 19 moves to the supporting plate 6. At the same time, the electromagnet jaws 20 are closed, and then the drive motor 2 moves the laundry piece moving slider 19 and the laundry piece coating 5 to the bottom of the nozzle 17, and at the same time, the drive m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com