Zero calibration method of three-degree-of-freedom parallel robot

A zero-point calibration and robot technology, applied in the direction of manipulators, program-controlled manipulators, manufacturing tools, etc., can solve problems such as inconvenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further elaborated below.

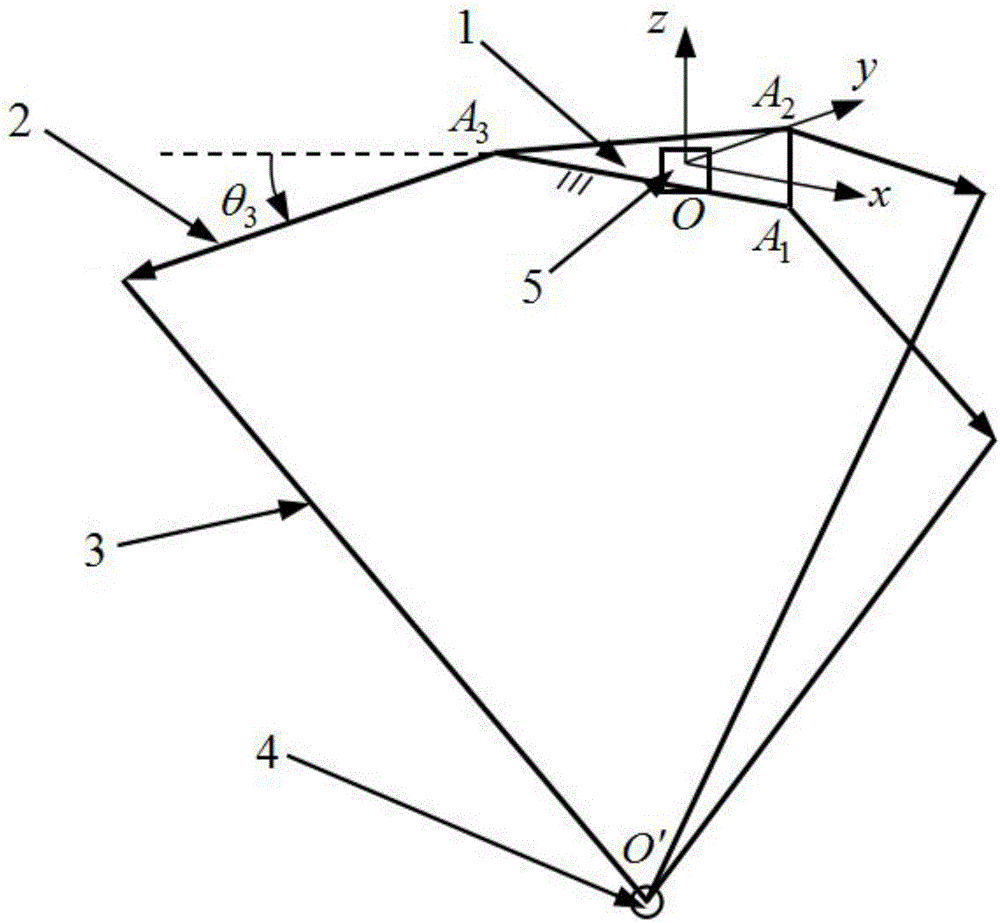

[0026] Such as figure 1 As shown, the three-degree-of-freedom high-speed parallel robot includes a static platform 1, a moving platform 4, and three kinematic branch chains with the same topology. Each kinematic branch chain includes two parts: the active arm 2 and the driven arm 3. In order to realize the calibration method of the present invention, a laser sensor 5 needs to be installed at the end of the static platform 1 in order to measure the change of the distance between the static platform 1 and the moving platform 4 in real time.

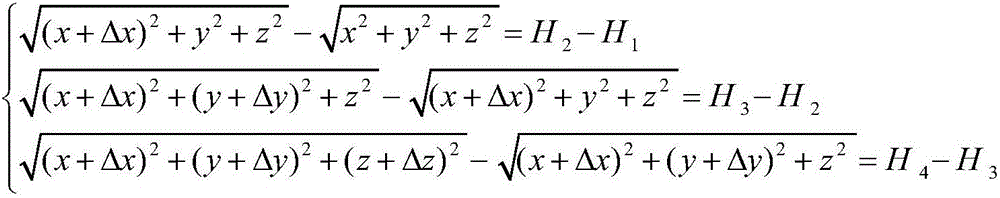

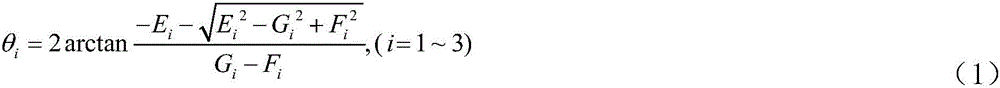

[0027] A rectangular coordinate system O-xyz is established in the workspace of the three-degree-of-freedom parallel robot, and the point of the inscribed circle of the three main arm rotation centers is used as the origin O of the coordinate system,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com