A kind of nano zinc oxide preparation technology

A nano-zinc oxide and a preparation process technology, applied in the field of nano-zinc oxide preparation technology, can solve problems such as unfavorable industrial production and cost saving, large labor consumption, cumbersome process, etc., so as to save labor costs and water resources, save production costs, Reasonable effect of preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

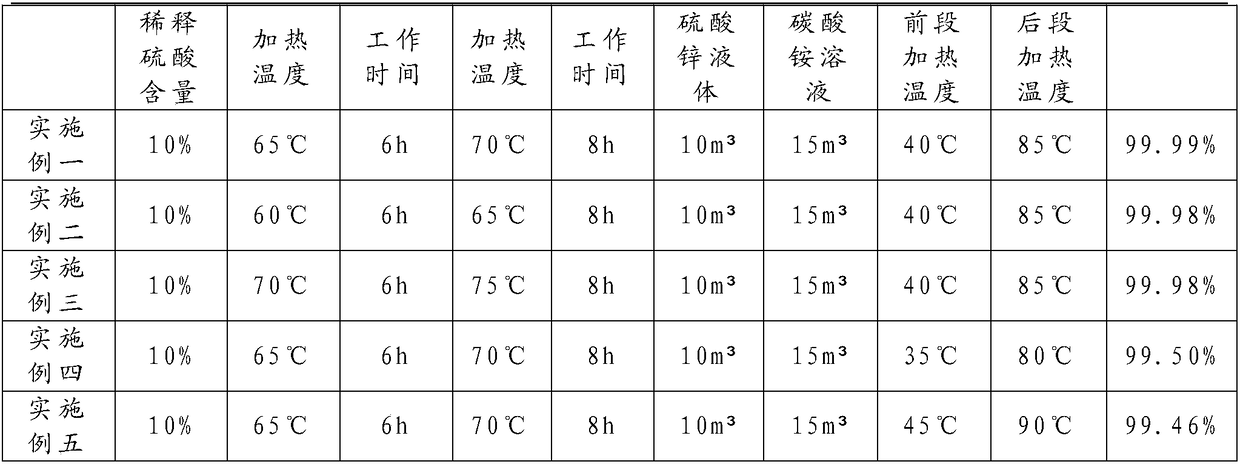

Examples

Embodiment Construction

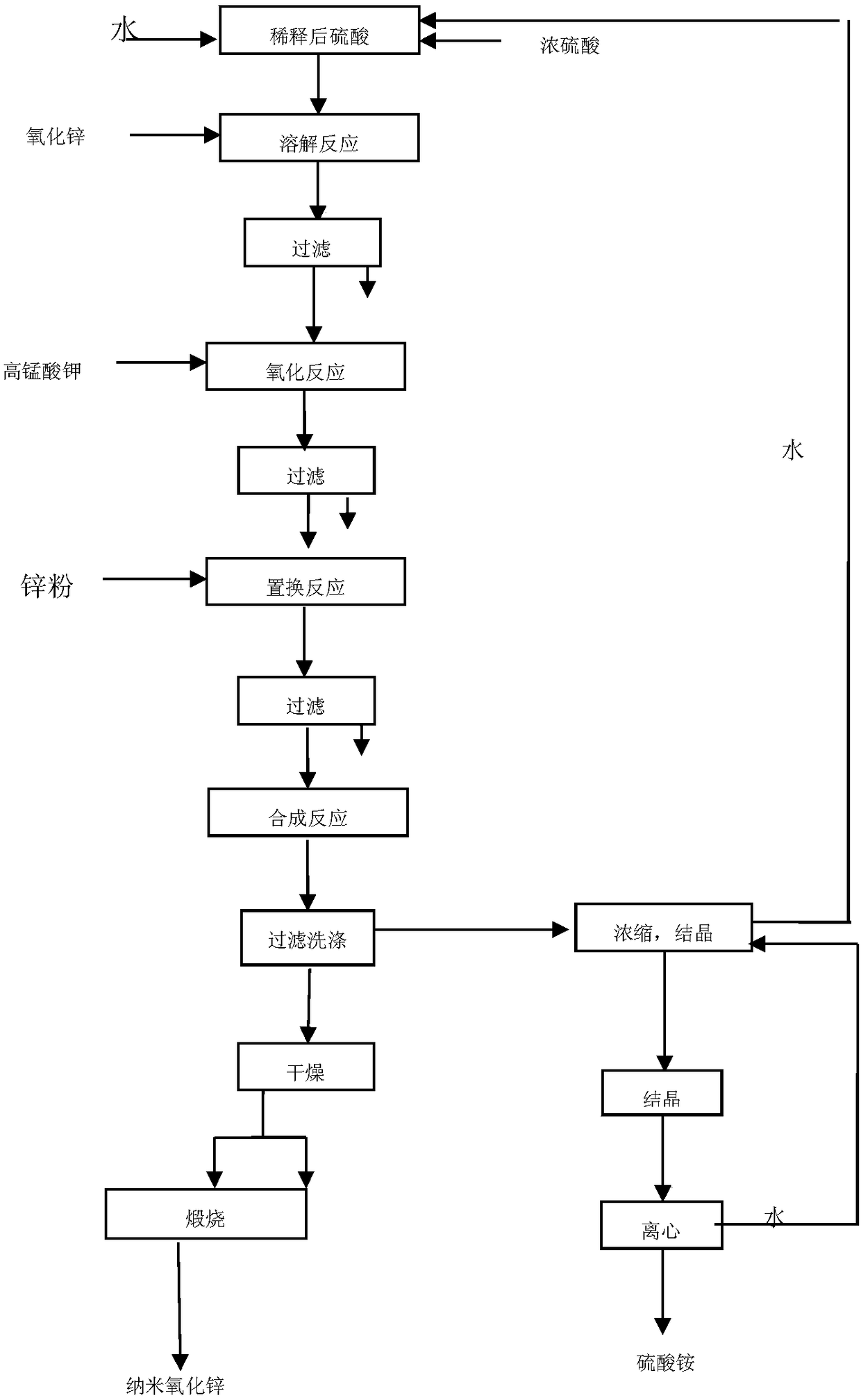

[0038] The present invention is described below in conjunction with accompanying drawing.

[0039] as attached figure 1 Shown is a nano-zinc oxide preparation process of the present invention, including oxide dissolution, oxidation reaction, replacement reaction, synthesis reaction, washing, rinsing and drying and calcining process steps; the specific process steps of embodiment one are as follows:

[0040] 1) oxide dissolution

[0041] The reaction equation is:

[0042] ZnO+H 2 SO 4 =ZnSO 4 +H 2 o

[0043] CuO+H 2 SO 4 =CuSO 4 +H 2 o

[0044] FeO+H 2 SO 4 =FeSO 4 +H 2 o

[0045] MnO+H 2 SO 4 =MnSO 4 +H 2 o

[0046] During production, dilute the concentrated sulfuric acid with water to 10% in the acidolysis tank, and then add the by-product zinc oxide raw material after stirring evenly. The zinc in the raw material mainly exists in the form of zinc oxide, and the by-product zinc oxide reacts with sulfuric acid in sulfuric acid solution to form Zinc sulfat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com