A multi-metal surface crystallization synergistic catalytic oxidation reactor

An oxidation reactor and synergistic catalysis technology, applied in chemical instruments and methods, oxidized water/sewage treatment, special compound water treatment, etc., can solve the problems of difficult solid-liquid separation, increased operating costs, and a large amount of iron sludge.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

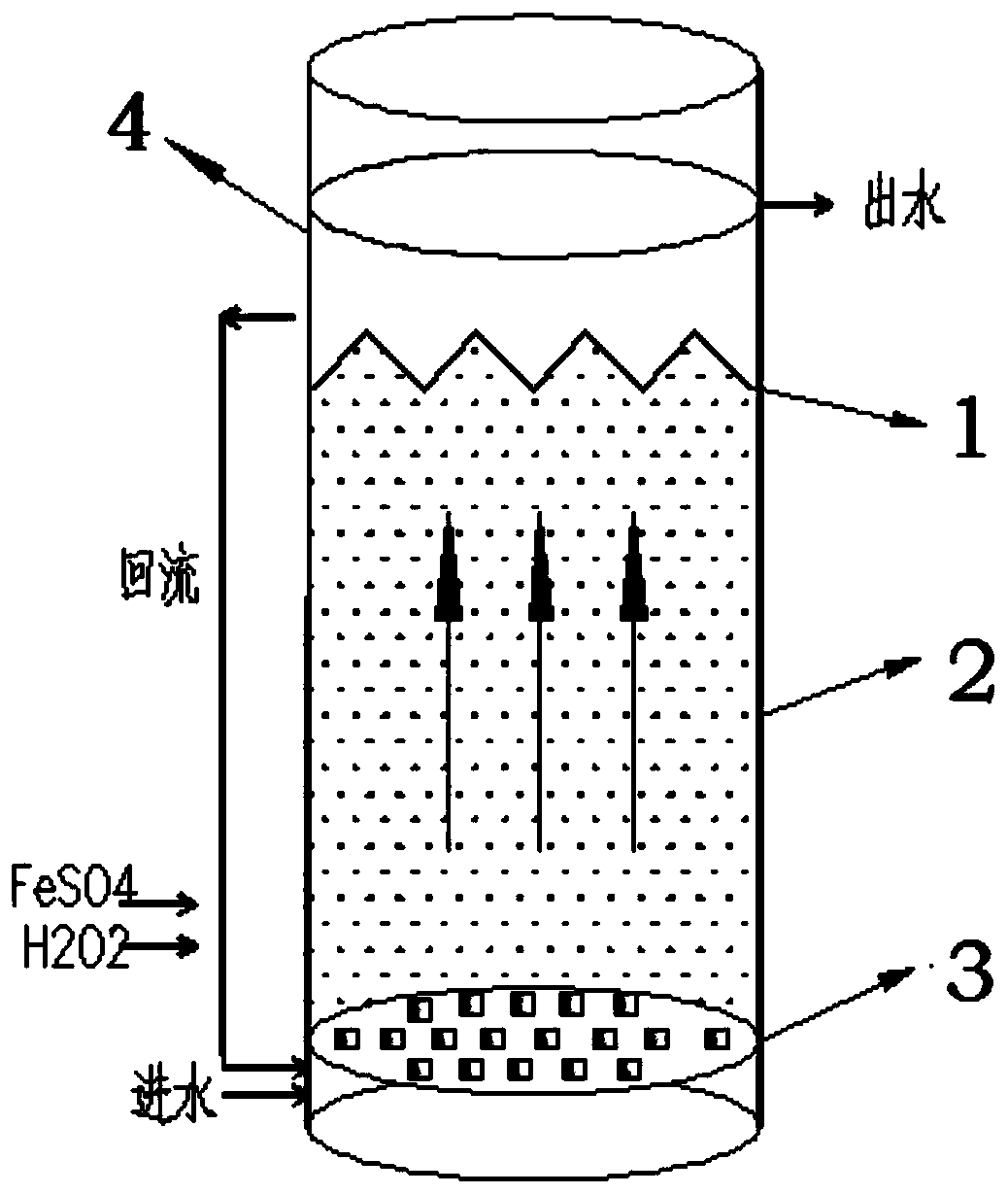

Embodiment Construction

[0009] experimental method

[0010] ① Use a lift pump to lift 200L of test wastewater to the original water tank;

[0011] ② Use 40% industrial grade sulfuric acid to adjust the pH of the above wastewater to 4;

[0012] ③Add about 1kg of polymetallic catalyst to the synergistic catalytic oxidation reactor, start the circulation pump, and adjust the flow rate to 200L / h.

[0013] ④Start the raw water pump, adjust the water inlet flow rate to 700ml / min, and start continuous water inlet;

[0014] ⑤ Start the dosing pump and add 30% H to the catalytic oxidation reactor 2 o 2 Agent, the catalytic oxidation reaction starts;

[0015] ⑥After being treated in the catalytic oxidation reactor, the effluent from the upper layer flows to the effluent tank by itself, and the catalyst flows in the reactor and does not flow out with the water;

[0016] ⑦ Collect treated water samples 2-3 hours after the start of the test. Then, adopt the batch test method, add 30% NaOH while stirring, ad...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com