Sewage treatment anaerobic reaction system and water treatment method

An anaerobic reaction and sewage treatment technology, which is applied in the field of water treatment to achieve the effect of increasing the decomposition rate, increasing the area of the separation zone, and achieving obvious effects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

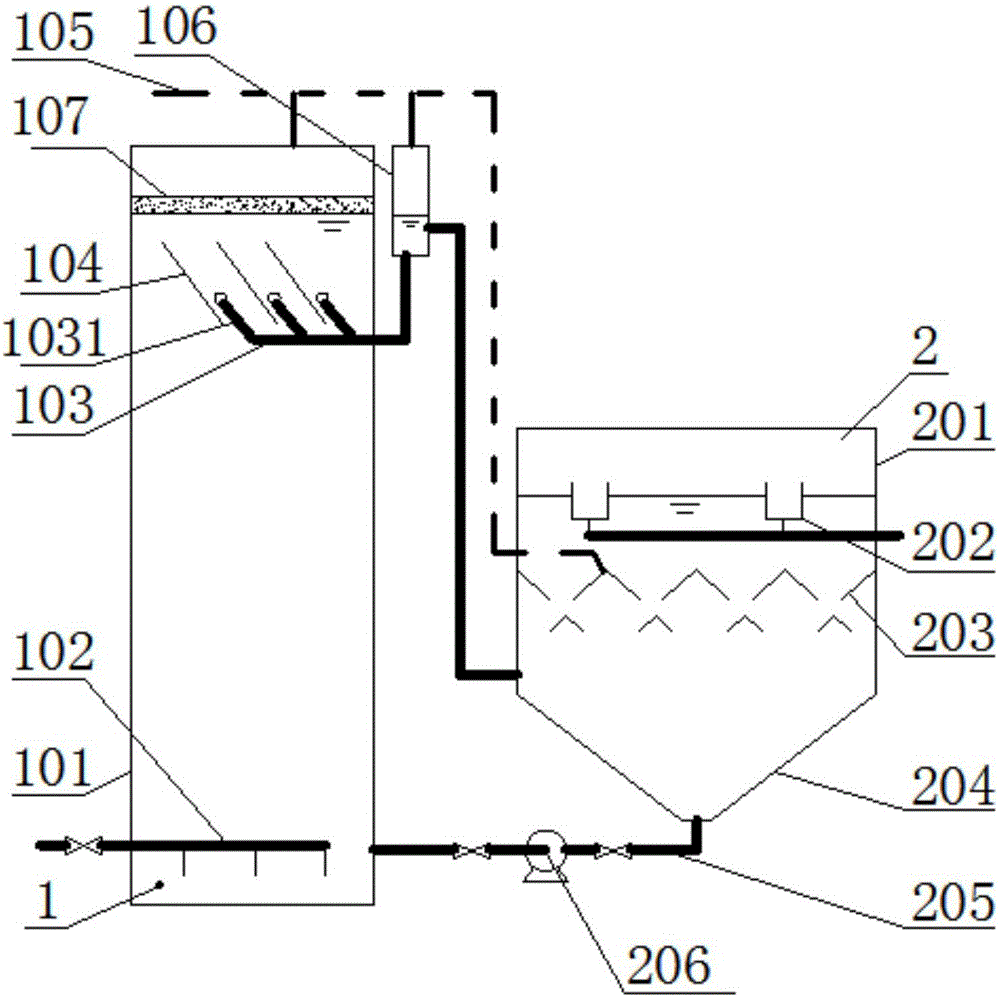

[0078] Such as figure 1 As shown, the present embodiment provides a sewage treatment anaerobic reaction system, comprising:

[0079] An anaerobic reaction tank 1 and a three-phase separation tank 2 provided separately, the water outlet of the anaerobic reaction tank 1 and the water inlet of the three-phase separation tank 2 are connected by a pipeline;

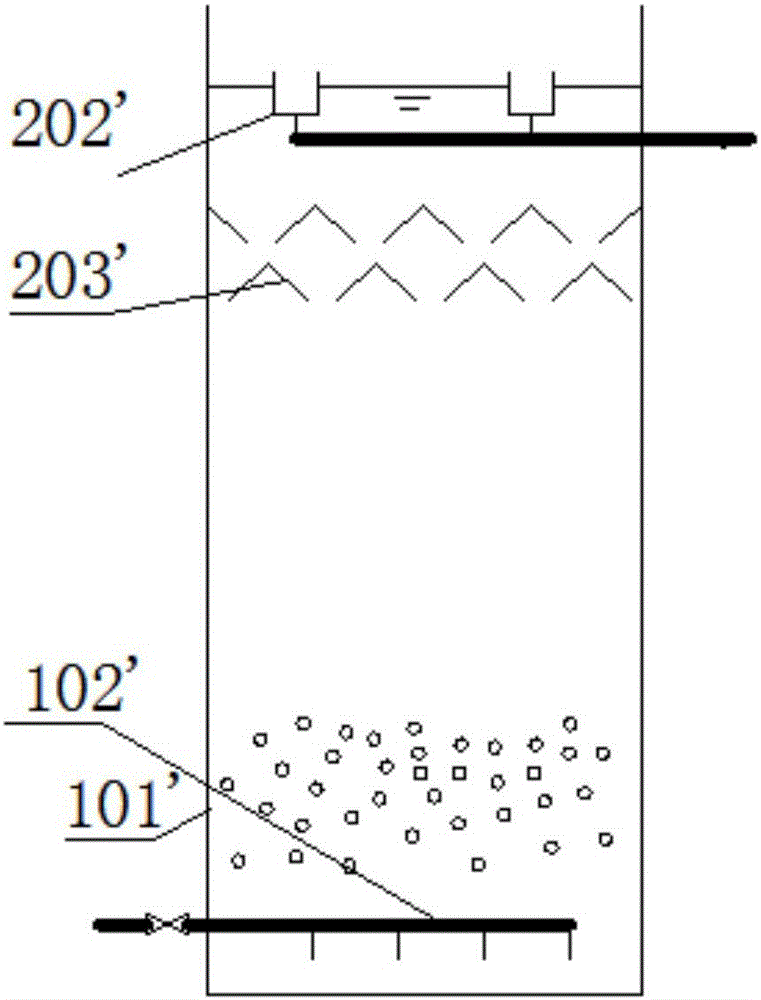

[0080] Anaerobic reaction tank 1 comprises anaerobic reaction tank body 101, water inlet system 102, water collection system 103 and biogas pipe 105, water inlet system 102 is arranged on the bottom in anaerobic reaction tank body 101, water collection system 103 is arranged In the middle and upper part of the anaerobic reaction pool body 101, the biogas pipe 105 is arranged on the top of the anaerobic reaction pool body 101;

[0081] Three-phase separation tank 2 comprises three-phase separation tank body 201, outlet weir 202, three-phase separator 203, sludge bucket 204, and outlet weir 202 is arranged on the top in three-p...

Embodiment 2

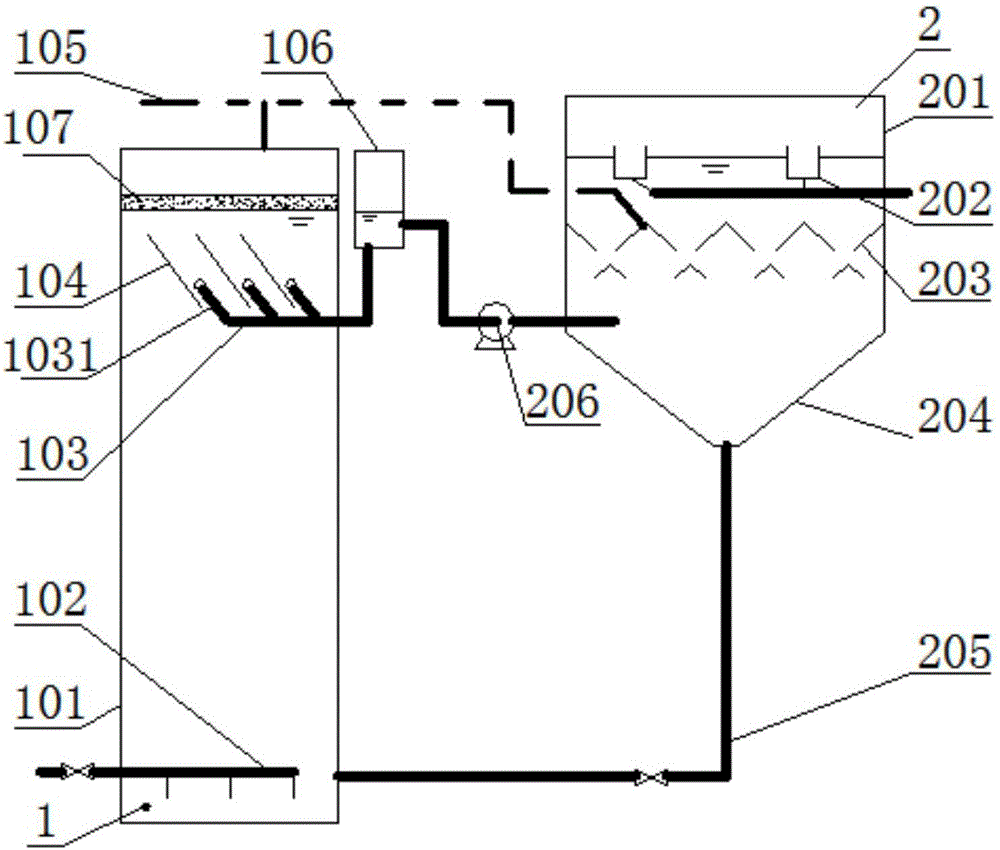

[0103] Such as figure 2 As shown, the difference between this embodiment and embodiment 1 is:

[0104] The setting elevation of the three-phase separation tank 2 that provides the sewage treatment anaerobic reaction system in embodiment 2 is higher than the setting elevation of the anaerobic reaction tank 1, therefore, the effluent of the anaerobic reaction tank 1 needs to be arranged in the anaerobic reaction tank The lift pump 206 on the pipeline between the outlet of the three-phase separation tank 2 and the water inlet of the three-phase separation tank 2 is lifted to the three-phase separation tank 2, and the sludge in the sludge hopper 204 can flow to the drain by gravity through the sludge return system 205 In the oxygen reaction tank 1 , the final outlet water is also discharged from the system through the outlet weir 202 .

[0105] Therefore, structurally, the lift pump 206 in this embodiment is arranged on the pipeline between the water outlet of the anaerobic reac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com