Polymerase chain reaction machine and temperature control system thereof

A technology of temperature control system and reaction instrument, which is applied in the direction of bioreactor/fermenter combination, specific-purpose bioreactor/fermenter, biochemical instrument, etc., and can solve the problems of low temperature control accuracy, mutual interference, and use limitations in different partitions sex issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

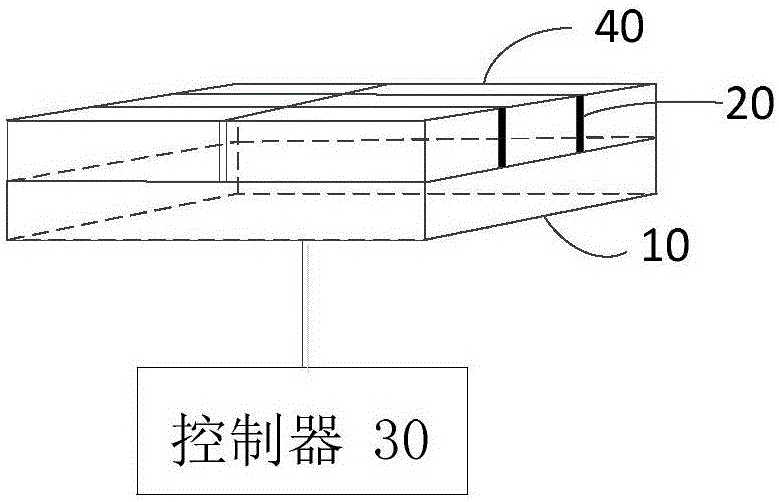

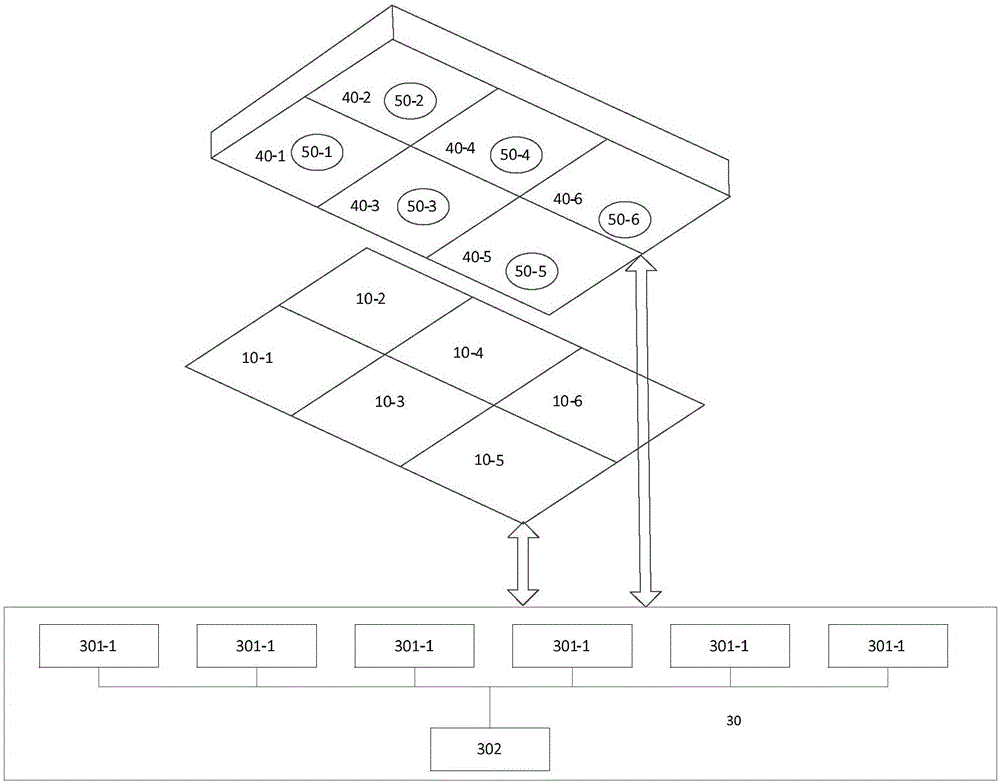

[0024] This embodiment provides a temperature control system for polymerase chain reaction instrument, such as figure 1 As shown, the control system includes: a plurality of heating modules 10 , a heat insulation layer 20 and a controller 30 . It should be noted that since the samples are placed on the porous reaction plate, the temperatures in different regions of the reaction described below are also the temperatures of the samples in the regions.

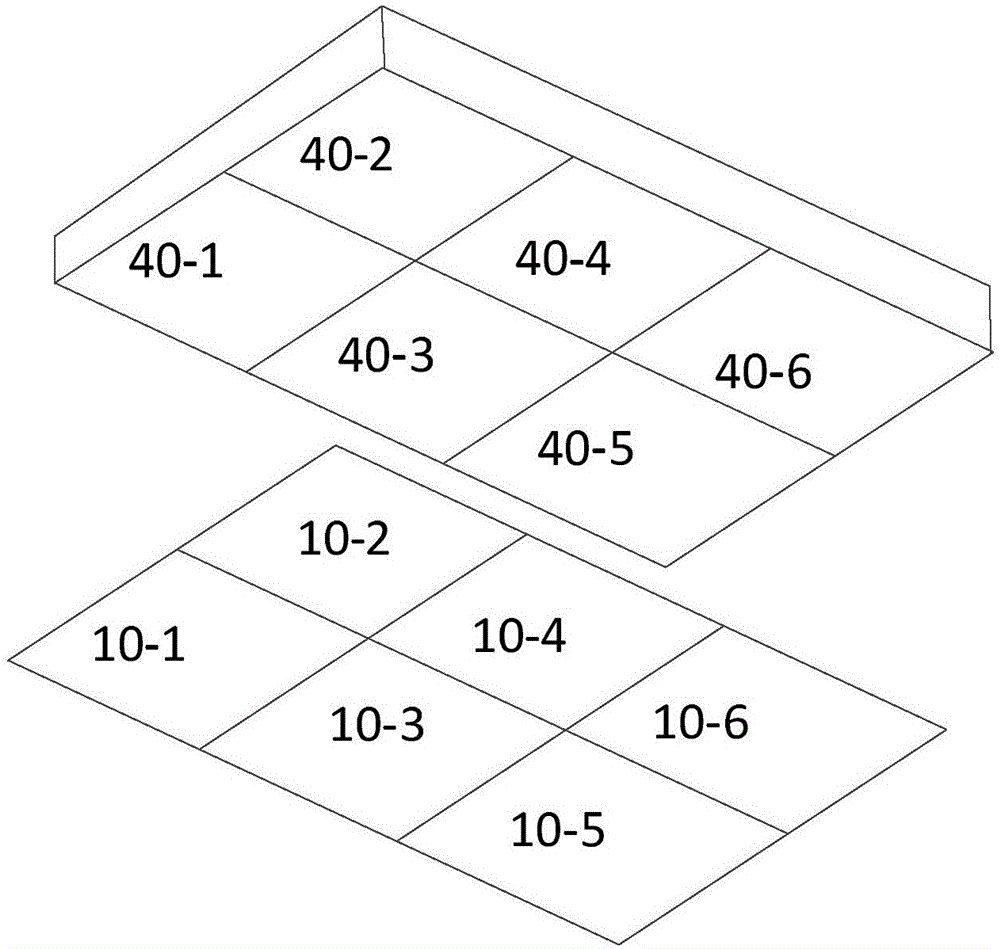

[0025] A plurality of heating modules 10 for temperature adjustment of different regions of the porous reaction plate 40 , wherein the porous reaction plate is pre-divided into a plurality of regions corresponding to the plurality of heating modules. Specifically, such as figure 2 As shown, the porous reaction plate 40 is pre-divided into a first area 40-1, a second area 40-2, a third area 40-3, a fourth area 40-4, a fifth area 40-5, and a sixth area 40- 6. The first heating module 10-1 is used to adjust the temperature of the...

Embodiment 2

[0041] This embodiment provides a polymerase chain reaction apparatus, which includes: the temperature control system described in Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com