Structure of steel-reinforced concrete column beam and column universal joint

A technology of concrete beams and general-purpose joints, which is applied in building structures, buildings, etc., can solve the problems of ungiven space layout of column stiffeners, poor cooperating performance of column-beam joints, and cumbersome column-beam construction. The effect of width-thickness ratio requirements, excellent seismic performance and fast construction speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

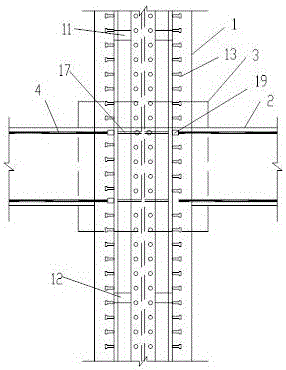

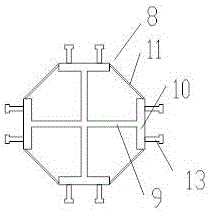

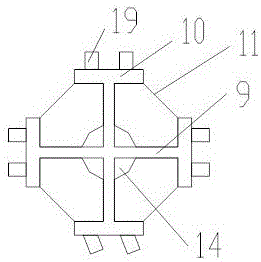

[0030] Please refer to Figure 1-6 , preferably, the present invention provides a structure of a steel concrete column-beam-column general joint, which includes a steel concrete column 1 and a steel concrete beam 2, and the steel concrete beam 2 and the steel concrete column 1 are cross-connected to form a beam-column general joint 3, And the steel concrete beam 2 is perpendicular to the steel concrete column 1. The steel concrete beam 2 is formed by arranging at least two rows of steel bars 4 and pouring concrete 5. The steel concrete beam 2 is composed of an X-direction steel concrete beam 6 and a Y-direction steel concrete beam 7. , compared with the traditional steel-concrete column-beam-column joint, the structure of the steel-concrete column-beam-column joint has high bearing capacity, good ductility, strong energy dissipation capacity, excellent seismic performance, no need for a large number of formwork, and fast construction speed, etc. Advantages: simple structure, f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com