Method for manufacturing blading member assembly, and blading member assembly

A technology of components and blades, applied in the field of blade components, can solve the problems of impossibility of manufacturing cooling holes, such as through drilling, complexity, poor coating quality, etc., to achieve excellent accessibility, fast processing, and good coating thickness Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

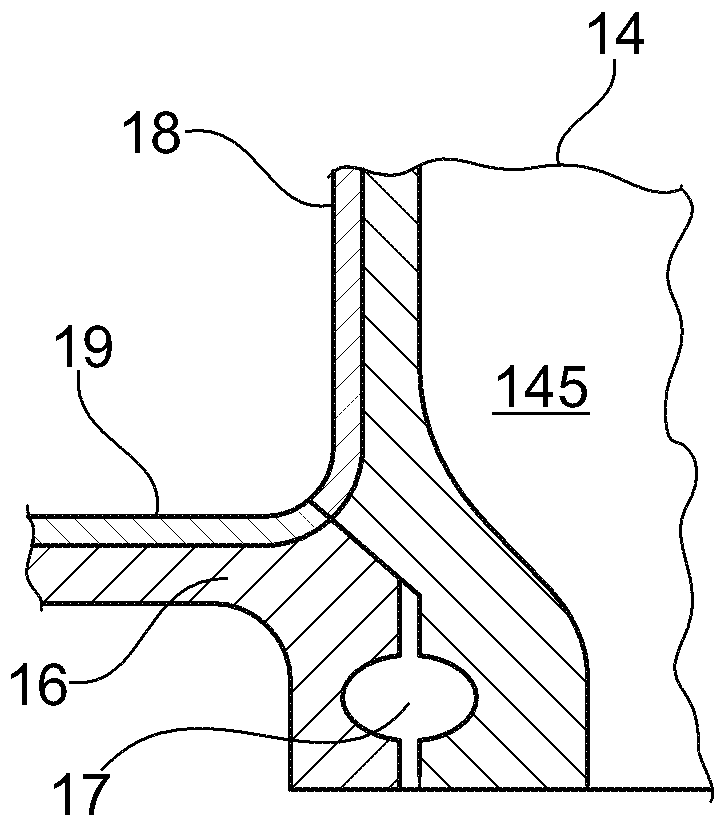

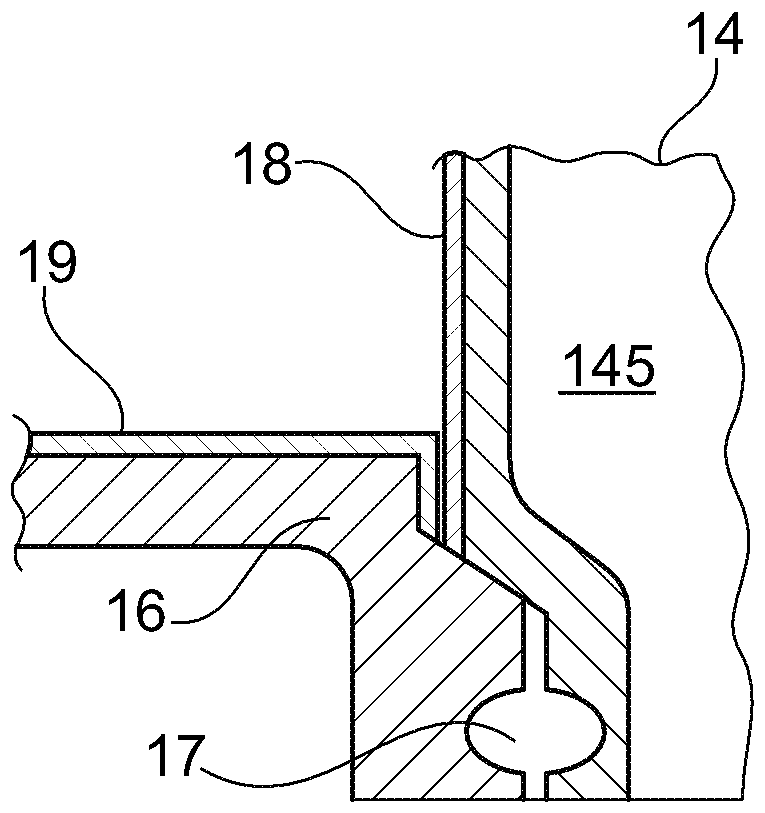

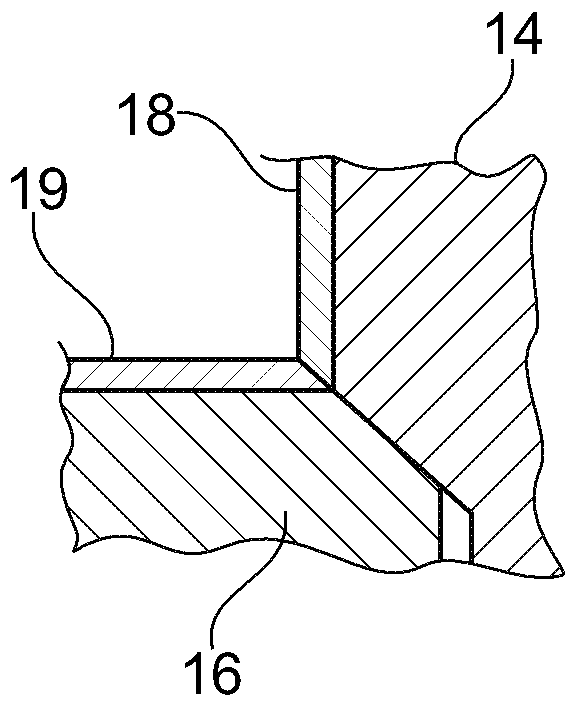

[0069] figure 1 The problem on which the subject matter of the present disclosure is based is depicted for informational purposes only. A blade part 1 is shown comprising an airfoil 11 , a first platform 12 and a second platform 13 . As will be readily understood, the outer surface of the airfoil 11 and the airfoil-facing surfaces of the platforms 12 , 13 constitute parts intended to be exposed to the working gas flow, or in short, to the hot gas side of the blade part 1 . surface. In the present description, it is shown how cooling openings are produced eg in an airfoil 11 . The tool spindle 2 is used to carry tools for producing cooling openings, such as drills, etching tools or laser sources. As can be seen, the tool spindle 2 interferes with the platform 13 when used to produce cooling openings in the airfoil 11 . The interference limits the ability to make cooling openings at required locations and at required angles relative to the surface of the airfoil 11 . Obviou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com