Ultra-compact and high-mixing-efficiency air exhaust system structure adopting de-swirl lobe mixer

An exhaust system and lobe technology, which is applied in the field of high-performance aviation gas turbofan engines, can solve the problems of limited tolerance, increased total pressure loss and thrust loss, and increased difficulty of lobe mixers, etc., to achieve strong anti-importation spin capacity, increase the thrust-to-weight ratio, increase the mixing efficiency and the effect of output thrust

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] In order to make the purpose, technical solutions and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the examples. The following examples are explanations of the present invention and the present invention is not limited to the following examples.

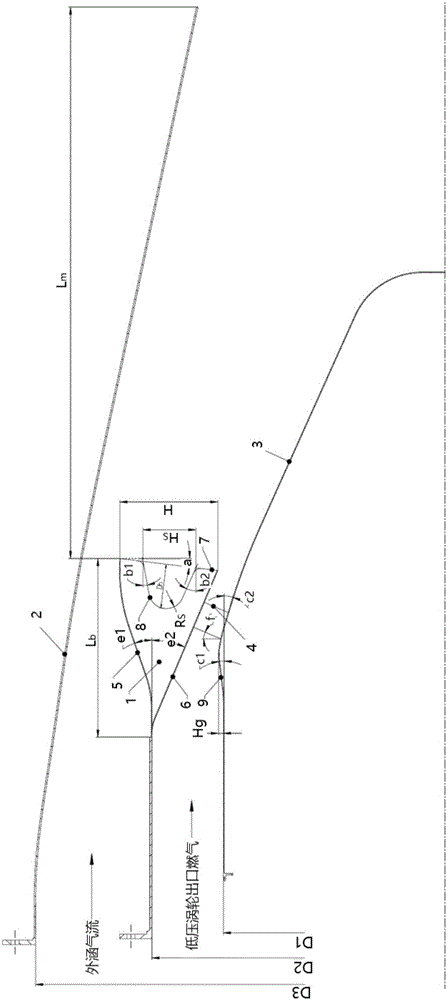

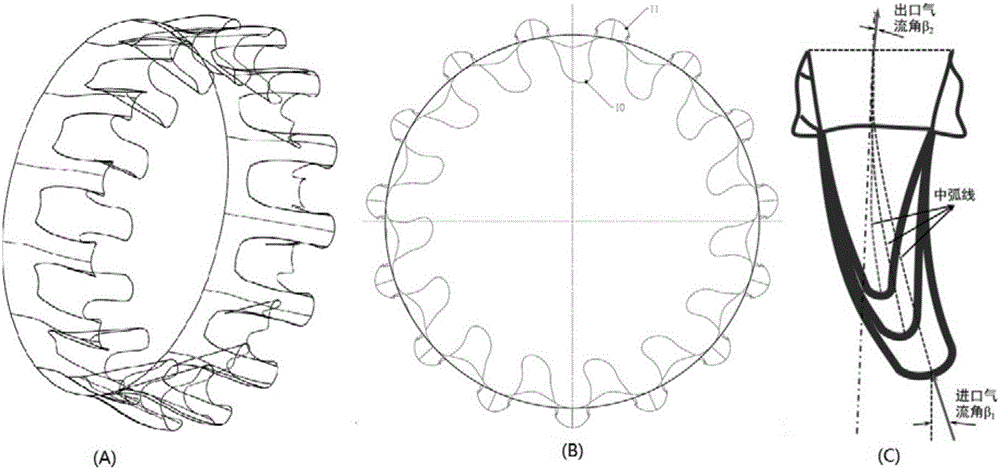

[0029] see figure 1 , 2 , the ultra-compact and high-blending efficiency derotation lobe mixing exhaust system structure of the present invention is suitable for high-performance small and medium bypass ratio aviation turbofan engines, and consists of a derotation lobe mixer 1, a mixing nozzle 2, and a belt drum The central cone 3 and the airfoil rib 4 are composed of four parts, wherein the derotation lobe mixer 1 is composed of a peak lobe 5 and a "special-shaped blade-like" wave trough lobe 6. The center cone is composed of a straight section, a bulge 9 and a tail cone. The derotation lobe mixer 1 and the center cone 3 with a bulge are conn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com