A method of rapidly evaluating quality of tobacco essence and spices

A technology for tobacco flavors, flavors and fragrances, which is applied in the directions of measuring devices, material separation, analysis materials, etc., can solve the problems of increased analysis time, difficulty in wide application, and impact on production efficiency, and achieves simplified pretreatment process, simple and fast process, and high efficiency. Contamination-free reproducible effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] Embodiment 1---Evaluate the quality of type A tobacco flavor and fragrance

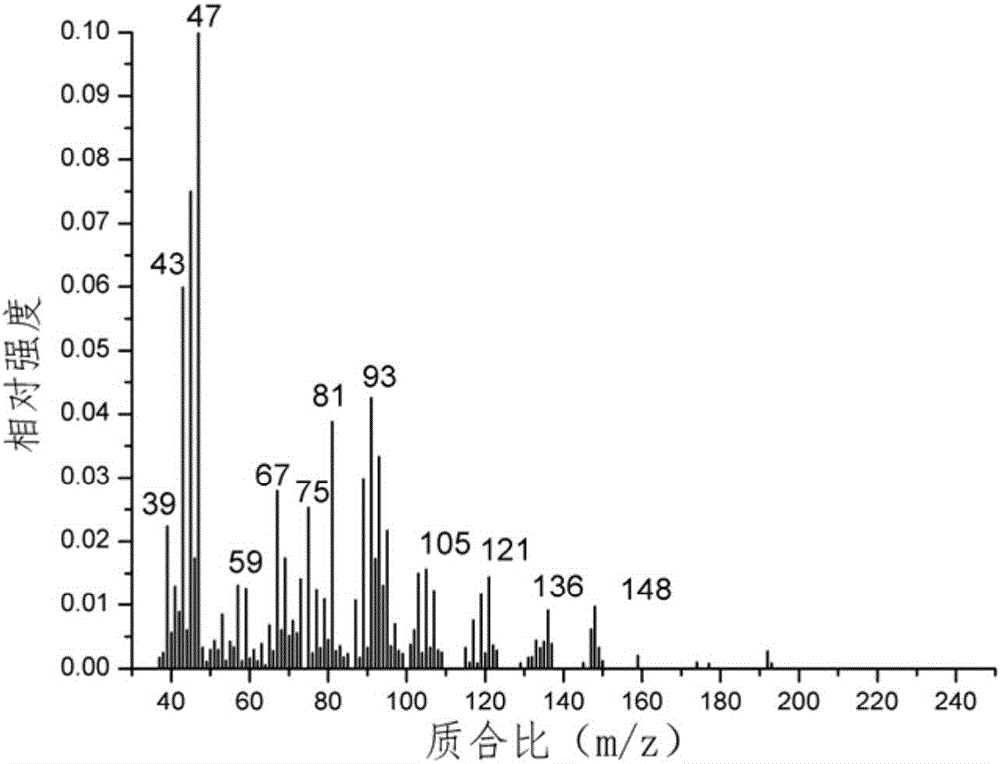

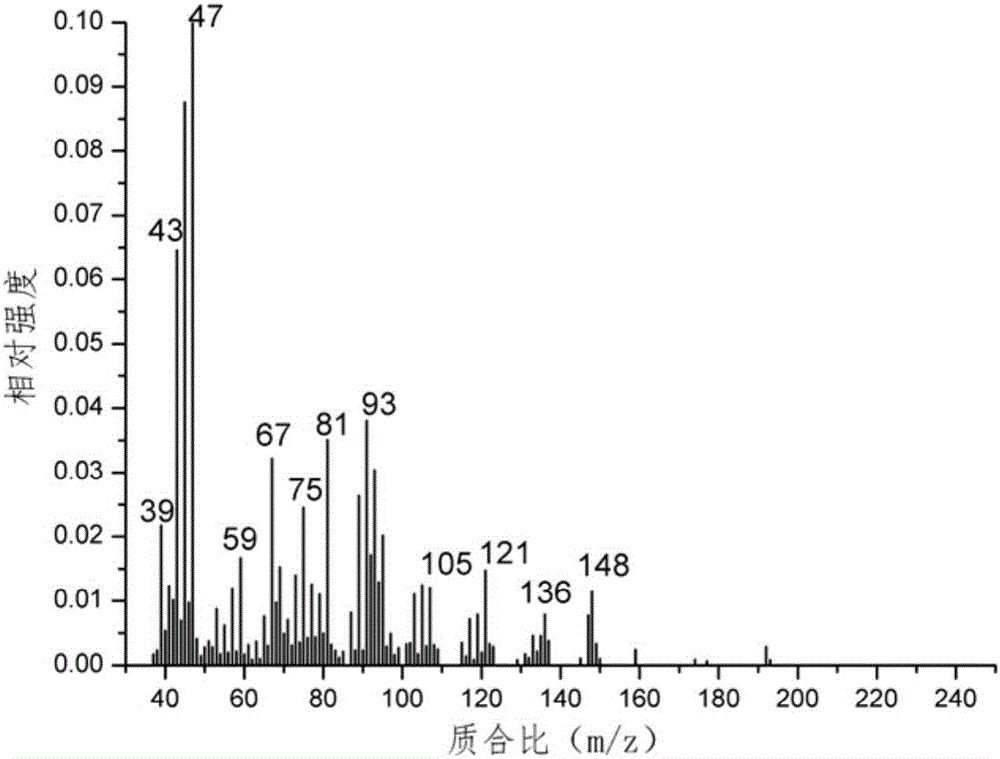

[0033] (1) Randomly select standard products of 25 production batches of Type A essence and mark them as A1, A2...A25 in turn, and obtain the mass spectrometry fingerprints of each batch of standard products according to the following operations respectively;

[0034] ①Weigh 100mg type A flavor standard and place it in a sealed 22mL headspace bottle, let it stand at room temperature (20°C) for 2min, then insert the solid-phase microextraction fiber DVB / CAR / PDMS into the headspace bottle, (20°C) enrich the sample for 10 minutes;

[0035] ②The chromatographic column in the gas chromatography-mass spectrometer is replaced by a deactivated empty fused silica capillary tube with a length of 5 meters and an inner diameter of 0.25 microns. At this time, the deactivated fused silica capillary tube is used as a connection between the gas chromatograph inlet and the mass spectrometer. transmission line ...

Embodiment 2

[0055] Repeat Example 1, with the following differences:

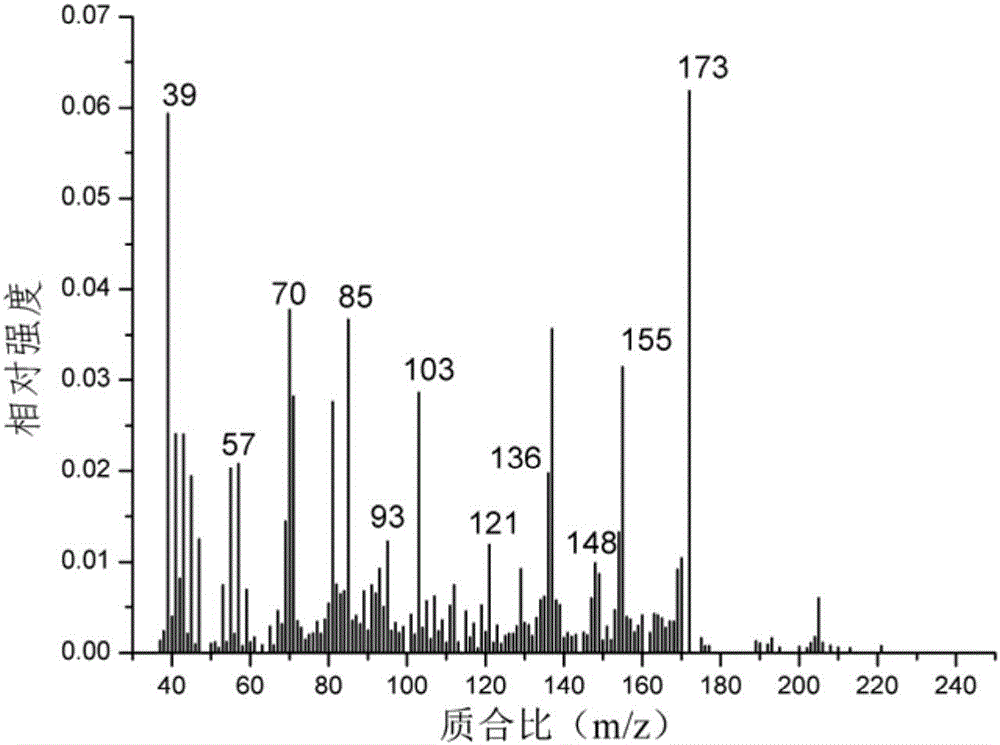

[0056] (1) Randomly extract 10 production batches of standard products of Type B flavor, and obtain the mass spectrometry fingerprints of each batch of standard products; among them, the solid phase microextraction fiber is DVB / PDMS, and the temperature of the injection port is 270°C. Set time 5min; image 3 It is the mass spectrometry fingerprint of the first batch (B1) standard product of Type B essence;

[0057] (2) The ions that exist in 8 (80% principle) samples are regarded as the common ions of the B-type flavor, and the result is that there are 155 common ions in the B-type flavor of 10 different batches, so finally 10 × 155 matrix (Table 4), where each row represents a sample and each column represents a variable. And the values of the same variable of different samples are averaged to obtain the average value of 155 variables, which is the digital standard mass spectrum fingerprint of type B essence ( F...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com