Novel method for producing electrolyte of lithium ion battery

A lithium-ion battery and electrolyte technology, applied in secondary batteries, circuits, electrical components, etc., can solve the problems of high heat preservation energy consumption, increase energy consumption, increase process time, etc., to improve production efficiency, reduce overall costs, The effect of low internal resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

[0024] A new method for producing lithium-ion battery electrolyte. Before producing and preparing lithium-ion battery electrolyte, first mix EC and at least one organic solvent required for preparing lithium-ion battery electrolyte according to 50%-80%: 20% -50% mass fraction ratio pre-mixed into an EC mixed solvent with a melting point less than or equal to 20°C, store or transport the EC mixed solvent at room temperature; when producing and preparing lithium-ion battery electrolyte, then add the EC mixed solvent to the Prepare in a reaction vessel.

[0025] Further, the other at least one organic solvent required for preparing the lithium-ion battery electrolyte is formed by mixing one or two or more of DMC, DEC or EMC in any proportion.

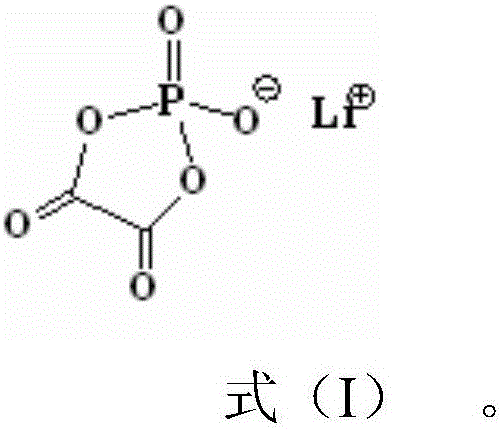

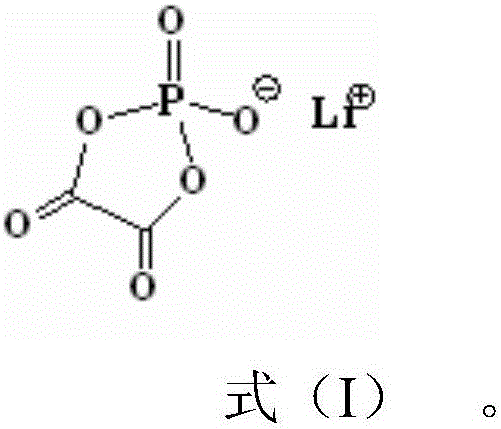

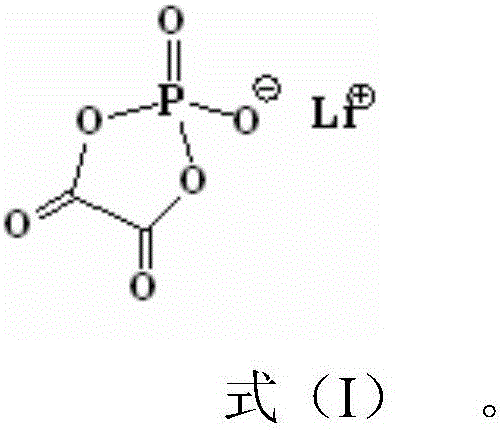

[0026] Further, when producing and preparing the lithium-ion battery electrolyte, electrolyte lithium salt and additives are also added, and the mass percent content of the EC mixed solvent in the lithium-ion battery electrolyte is 20-60%;...

Embodiment 1

[0041] A new method for producing lithium-ion battery electrolyte. Before producing and preparing lithium-ion battery electrolyte, EC and other at least one organic solvent required for preparing lithium-ion battery electrolyte are mixed according to the mass fraction of 80%: 20%. After pre-mixing into an EC mixed solvent with a melting point of less than or equal to 20°C, the EC mixed solvent is stored or transported at room temperature; when producing and preparing lithium-ion battery electrolyte, the EC mixed solvent is then added to the reaction container for preparation.

[0042] The at least one organic solvent required to prepare the lithium-ion battery electrolyte is DMC.

Embodiment 2

[0044] A new method for producing lithium-ion battery electrolyte. Before producing and preparing lithium-ion battery electrolyte, EC and other at least one organic solvent required for preparing lithium-ion battery electrolyte are mixed according to the mass fraction of 50%:50%. After pre-mixing into an EC mixed solvent with a melting point of less than or equal to 20°C, the EC mixed solvent is stored or transported at room temperature; when producing and preparing lithium-ion battery electrolyte, the EC mixed solvent is then added to the reaction container for preparation.

[0045] The at least one organic solvent required for other preparations of the lithium-ion battery electrolyte is provided by DEC.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com