A safe lithium ion power battery

A power battery and lithium-ion technology, which is applied in the field of safe lithium-ion power batteries, can solve problems such as inability to effectively avoid contact short circuits, and achieve the effect of improving safety performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

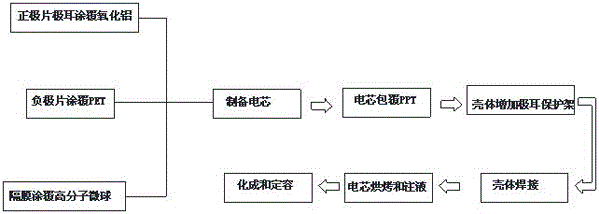

Image

Examples

Embodiment 1

[0028] Preparation of tab-coated positive electrode sheet: After the positive electrode sheet prepared according to the comparative example is completed, aluminum oxide coating is applied to the positive electrode tab with a coating thickness of 4-8 μm, and the coated area is the positive electrode current collector tab . The alumina coating is composed of the following components by mass percentage: 10-30% binder L132, 70-90% alumina particles;

[0029] Preparation of PET-coated negative electrode sheet: After the positive electrode sheet prepared according to the comparative example is completed, a PTC coating with a thickness of 3 μm is coated again on the negative electrode coating area. The position of the PTC coating is exactly the same as that of the negative electrode coating area. The PTC coating is composed of the following components by mass percentage: 65-92% of PTC material, 3-20% of conductive carbon black and 5-15% of polyvinylidene binder;

[0030] Preparation...

Embodiment 3

[0036] The difference from Example 2 is that the thickness of the negative electrode PET coating is 5 microns, and the others are the same as in Example 2, and will not be repeated here.

Embodiment 4

[0038] The difference from Example 2 is that the thickness of the positive electrode lug coating is 3 microns, and the others are the same as in Example 2, and will not be repeated here.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| coating thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com