Polygonal laser gain structure, laser oscillator and laser amplifier

A laser amplifier and laser gain technology, applied in the laser field, can solve problems such as complex cascade structure of thin-sheet lasers, limitation of laser amplification output energy, complex structure of thin-sheet lasers, etc., to achieve beam quality output, high beam quality output, and compact structure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

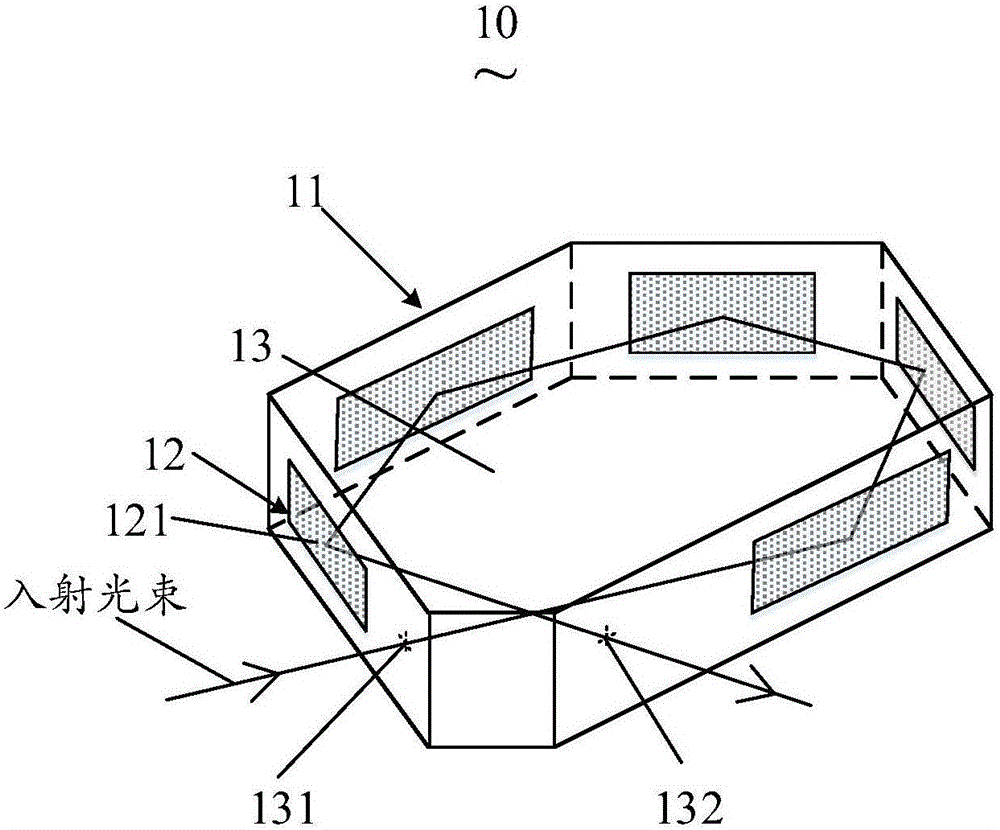

[0039] see figure 1 , figure 1 It is a structural schematic diagram of a polygonal laser gain structure provided by an embodiment of the present invention. Such as figure 1 As shown, the polygonal laser gain structure 10 of this embodiment includes n side faces 11 . The polygonal laser gain structure 10 also includes a doped region 12 and an undoped region 13 . Wherein, the doped region 12 is formed on the m sides of the polygonal laser gain structure 10, the doped region 12 is doped with active ions 121, and the doped region 12 is pumped by the pump beam for amplifying and reflecting the laser beam .

[0040] Where n is preferably greater than or equal to 4, m is preferably greater than or equal to 3, and m is less than or equal to n. In this embodiment, n is 6, and m is 5. It should be understood that other values of n and m may be used, for example, both m and n are 6, that is, a doped region 12 is formed on each side 11 . n can also be equal to 3. The present inv...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com