Steel plate for high-strength container and manufacturing method thereof

A manufacturing method and high-strength technology, applied in the direction of manufacturing tools, metal rolling, furnace types, etc., can solve the problems of reducing the cost of canning, difficult to balance ductility and strength, etc., to improve curling processability and ensure high strength And high ductility, not easy to wrinkle effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

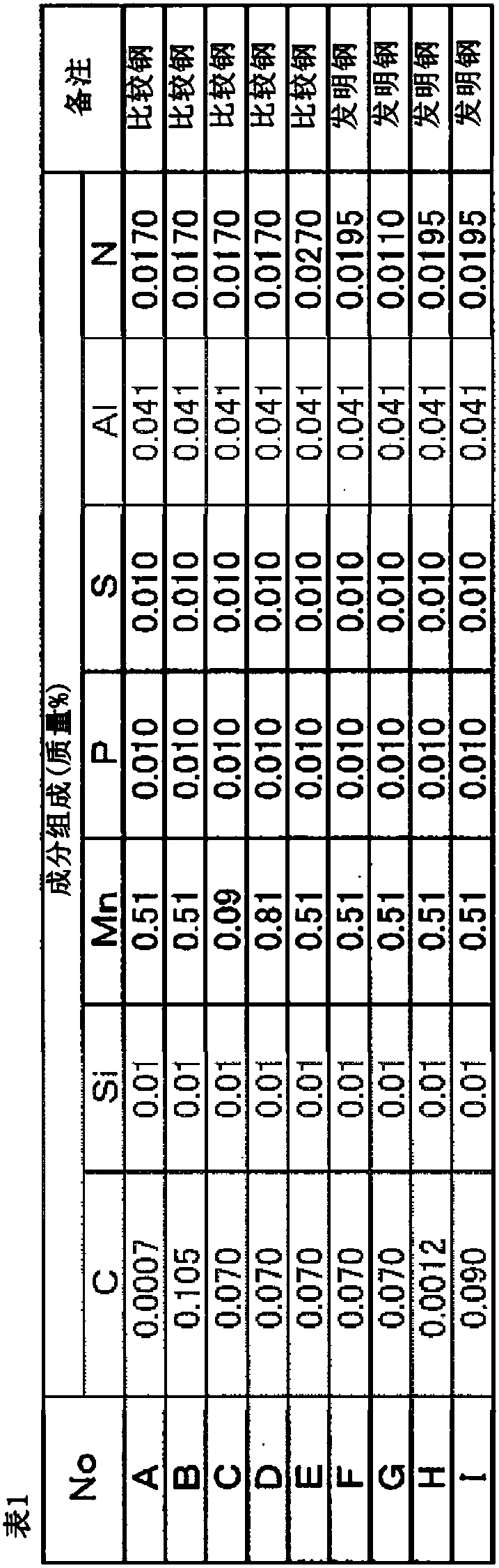

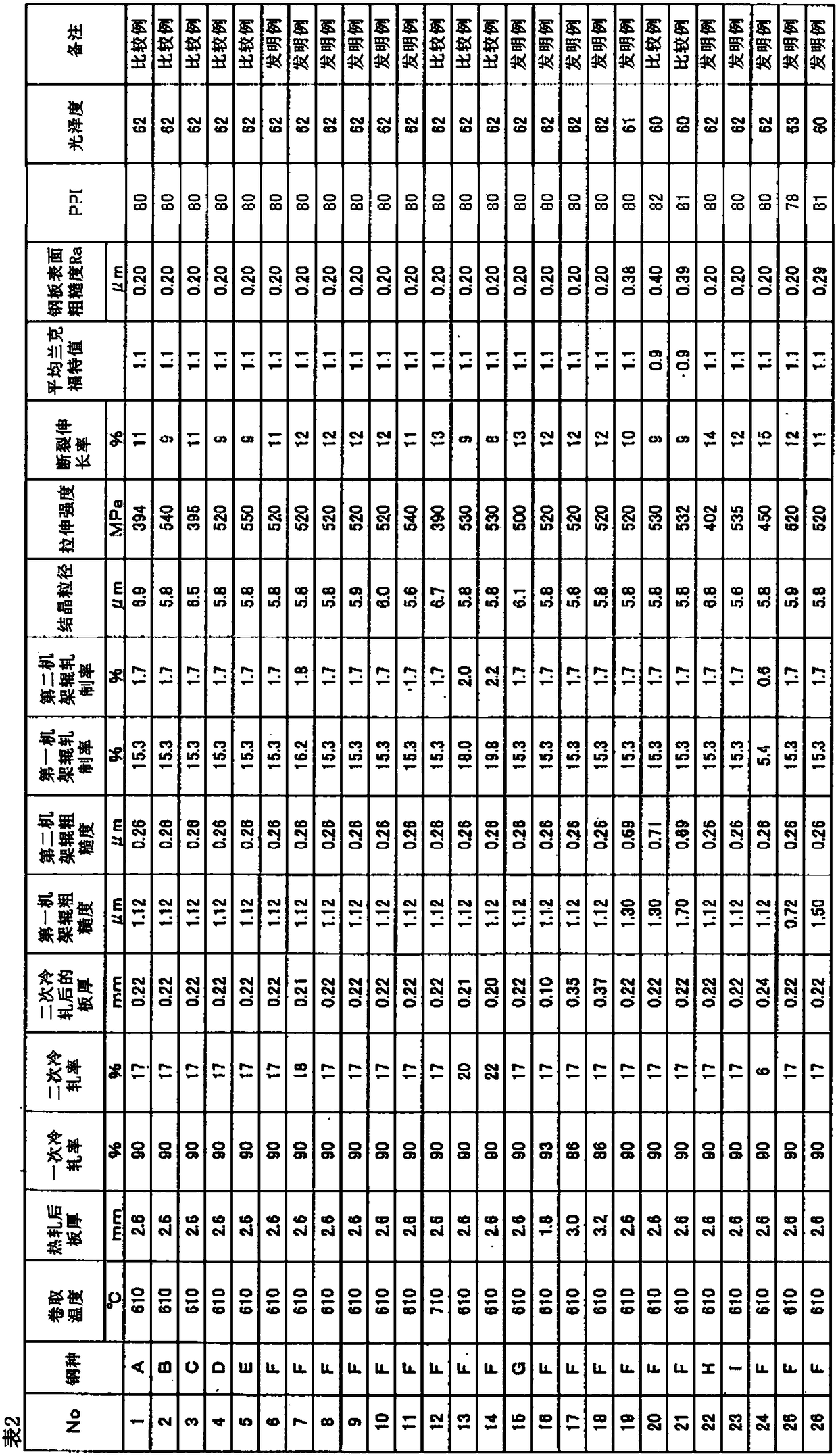

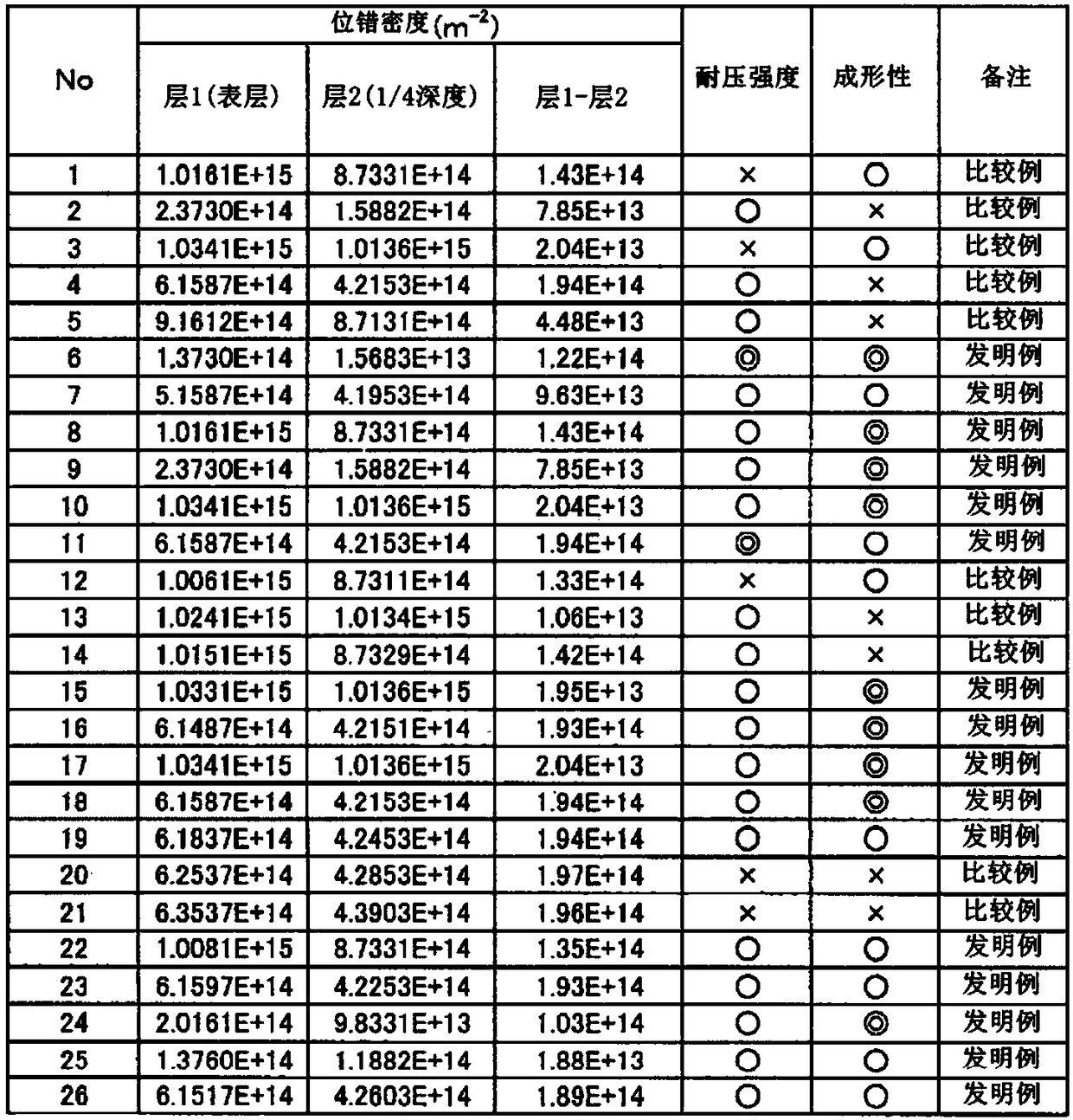

[0086] A steel containing the composition shown in Table 1, with the balance consisting of Fe and unavoidable impurities was smelted in a real machine converter, and a billet was obtained by continuous casting. The obtained slabs were reheated at 1230°C, and then hot-rolled and primary cold-rolled under the conditions shown in Table 2. The finishing temperature of the hot rolling was set at 890°C, and pickling was performed after the first cold rolling. Next, after primary cold rolling, continuous annealing at a soaking temperature of 670° C. and a soaking time of 20 seconds, and secondary cold rolling under the conditions shown in Table 2 were performed.

[0087] In addition, the roughness of the roll of the 1st stand and the roughness of the roll of the 2nd stand measured the surface roughness Ra of the steel plate defined in JIS B 0601 by the method defined in JIS B0633.

[0088] Sn plating was continuously performed on both sides of the steel sheet obtained as above, and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com