Repair method for automobile motor rotor

A motor rotor and repair method technology, which is applied in the field of motor components, can solve problems such as low precision and strength, low motor efficiency, and large frictional resistance, and achieve the effects of simplifying equipment, increasing efficiency, and reducing frictional resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

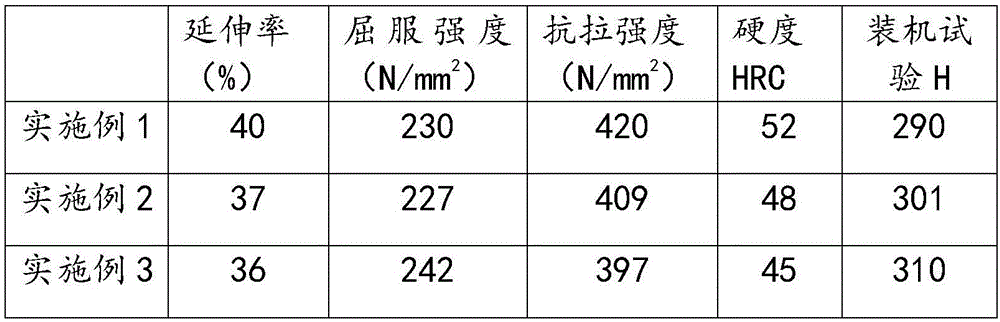

Examples

Embodiment 1

[0019] A method for repairing an automobile motor rotor, comprising the following steps:

[0020] (1) Mixing materials: take by weight percentage the copper of 2.6%, the silicon of 0.5%, the graphite of 0.7%, the titanium of 0.01%, the boron of 0.05%, the nickel of 2.4%, the manganese of 0.6%, the manganese of 0.3% Molybdenum, the balance is iron and unavoidable impurities, mixed into mixed powder;

[0021] (2) Primary baking: Install the rotor pressing mold on the press, put mixed powder into the cavity of the mold, heat up to 130°C at a heating rate of 2°C / min, press into a primary baking billet, and keep warm for 10h. The pressing pressure is 600MPa;

[0022] (3) Secondary baking: Install the rotor pressing mold on the press, put the first-time baking billet into the mold cavity, heat up to 135°C at a heating rate of 2°C / min, and press it into the second baking Blank, heat preservation 8h, pressing pressure 650MPa;

[0023] (4) Sintering: Sinter the secondary baked compa...

Embodiment 2

[0027] A method for repairing an automobile motor rotor, comprising the following steps:

[0028] (1) Mixing: Weigh 0.1% copper, 0.4% silicon, 0.9% graphite, 0.03% titanium, 0.03% boron, 1.8% nickel, 0.5% manganese, 0.4% Molybdenum, the balance is iron and unavoidable impurities, mixed into mixed powder;

[0029] (2) Primary baking: install the rotor pressing mold on the press, put mixed powder into the cavity of the mold, heat up to 140°C at a heating rate of 2°C / min, press into a primary baking billet, and keep warm for 10h. The pressing pressure is 600MPa;

[0030] (3) Secondary baking: Install the rotor pressing mold on the press, put the primary baking billet into the cavity of the mold, heat up to 130°C at a heating rate of 2°C / min, and press for secondary baking Blank, heat preservation 8h, pressing pressure 680MPa;

[0031] (4) Sintering: Sinter the secondary baked compact in a vacuum pressure sintering furnace to obtain a sintered material, the vacuum degree is les...

Embodiment 3

[0035] A method for repairing an automobile motor rotor, comprising the following steps:

[0036] (1) Mixing materials: take by weight percentage the copper of 1.2%, the silicon of 0.2%, the graphite of 0.5%, the titanium of 0.02%, the boron of 0.01%, the nickel of 2.1%, the manganese of 0.75%, the manganese of 0.2% Molybdenum, the balance is iron and unavoidable impurities, mixed into mixed powder;

[0037] (2) Primary baking: install the rotor pressing mold on the press, put mixed powder into the cavity of the mold, heat up to 135°C at a heating rate of 2°C / min, press into a primary baking billet, and keep warm for 10h. The pressing pressure is 680MPa;

[0038] (3) Secondary baking: Install the rotor pressing mold on the press, put the first-time baking billet into the mold cavity, heat up to 135°C at a heating rate of 2°C / min, and press it into the second baking Blank, heat preservation 8h, pressing pressure 640MPa;

[0039] (4) Sintering: Sinter the secondary baked comp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com