A kind of opening device and opening method for reinforcing double-angle steel rods of trusses

A technology of truss rods and double-angle steel, which is applied in the field of double-angle steel rod reinforcement opening devices, which can solve the problems of reduced bearing capacity, long cycle, corrosion of rods and nodes, etc., and achieves small heat-affected zone and simple use process , Improve the effect of comprehensive benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

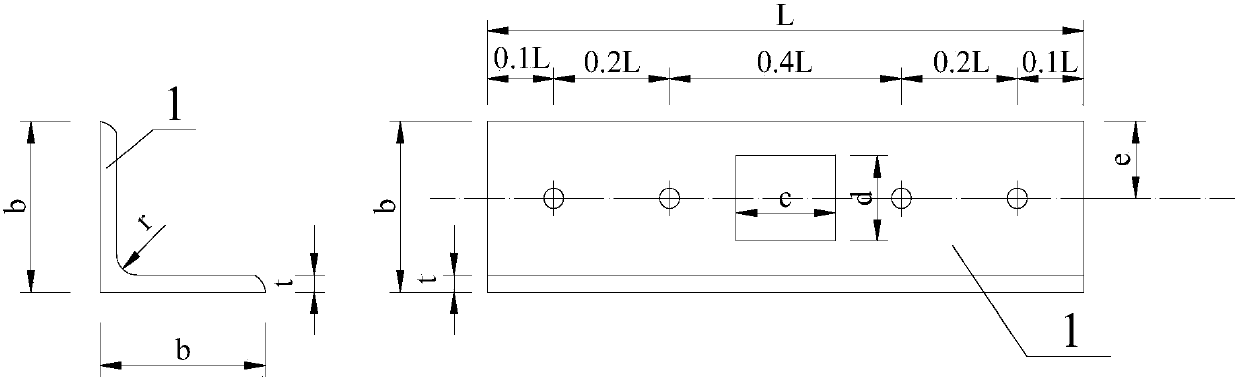

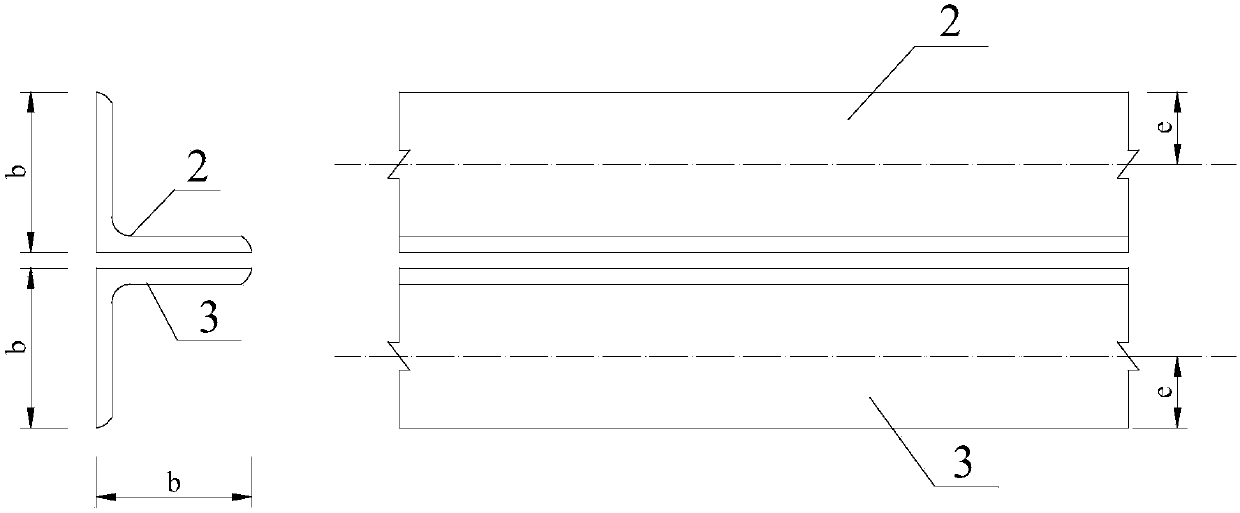

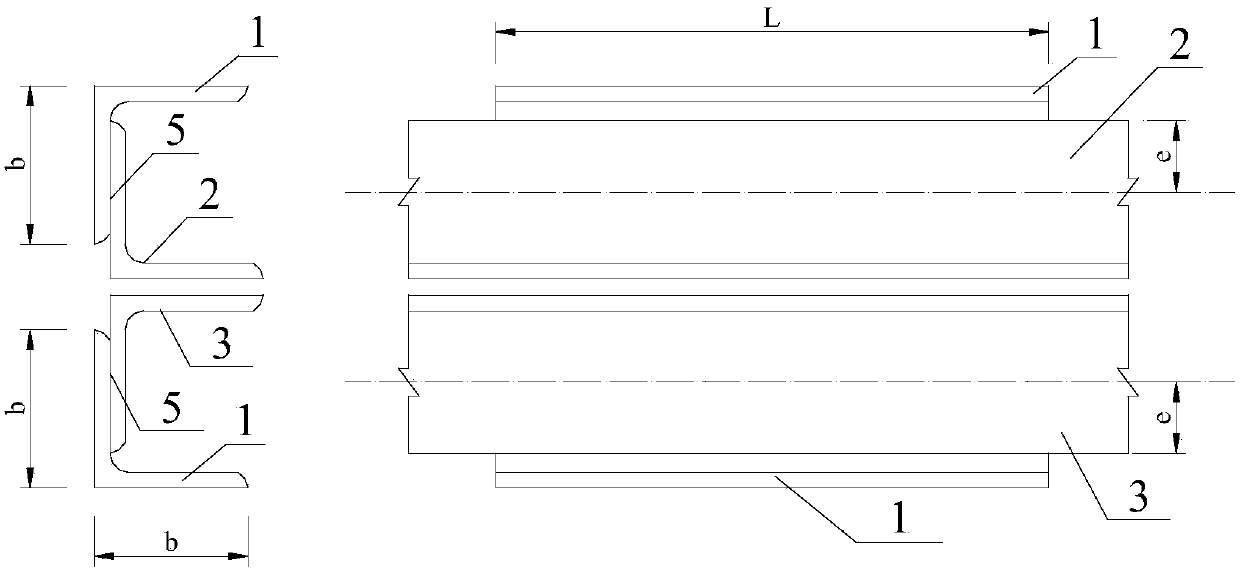

Embodiment 1

[0053] The invention was successfully implemented in the reinforcement of prestressed steel strands in the belt corridor of a coal preparation plant. The belt corridor was built in the 1980s. After more than 30 years of use, the lower chords have been severely corroded due to the accumulation of coal slime , the bearing capacity decreased significantly. In order to eliminate potential safety hazards, prestressed steel strands are used for tension reinforcement. Since the prestressed steel strands need to pass through some rods, these rods need to be reinforced and opened. According to the original design drawings, calculate the stress of the rods that need to be reinforced and open holes, and then calculate according to formula (1) and formula (2), select the reinforced angle steel 1, and carry out the reinforcement and hole treatment according to the specific implementation steps. In this example, according to the method of the present invention, the bar is successfully reinf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com