Gel polymer electrolyte and secondary battery comprising the same

A gel polymer and secondary battery technology, which is applied in the direction of non-aqueous electrolyte batteries, secondary batteries, electrolyte immobilization/gelation, etc., can solve the problems of reduced mobility and electrochemical properties, and achieve improved ion Effects of conductivity, leakage prevention, and ease of application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

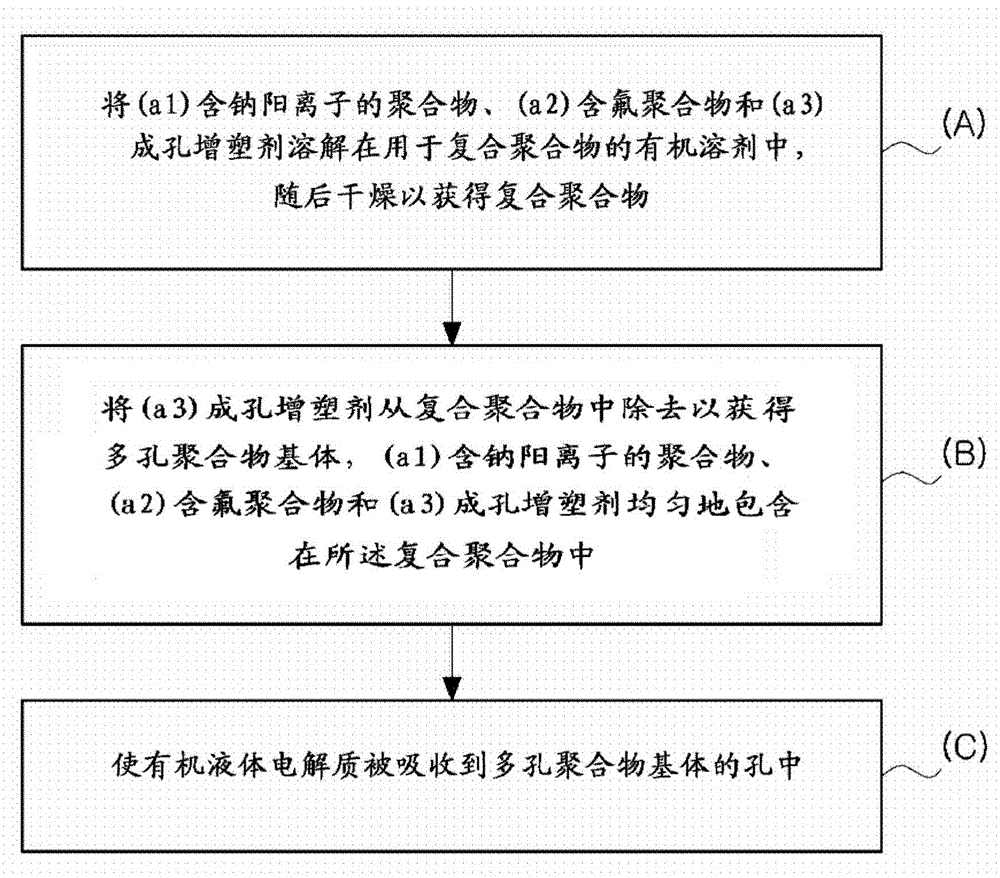

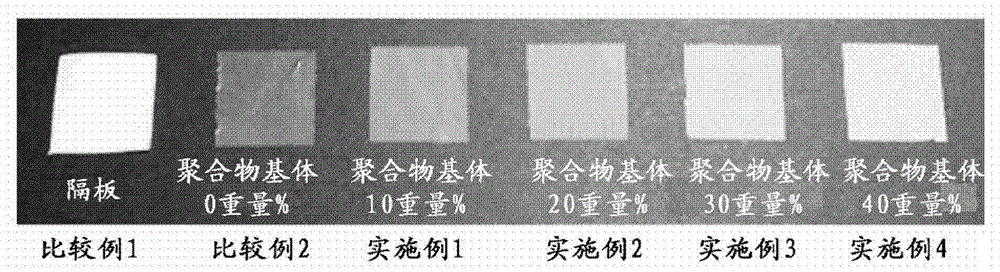

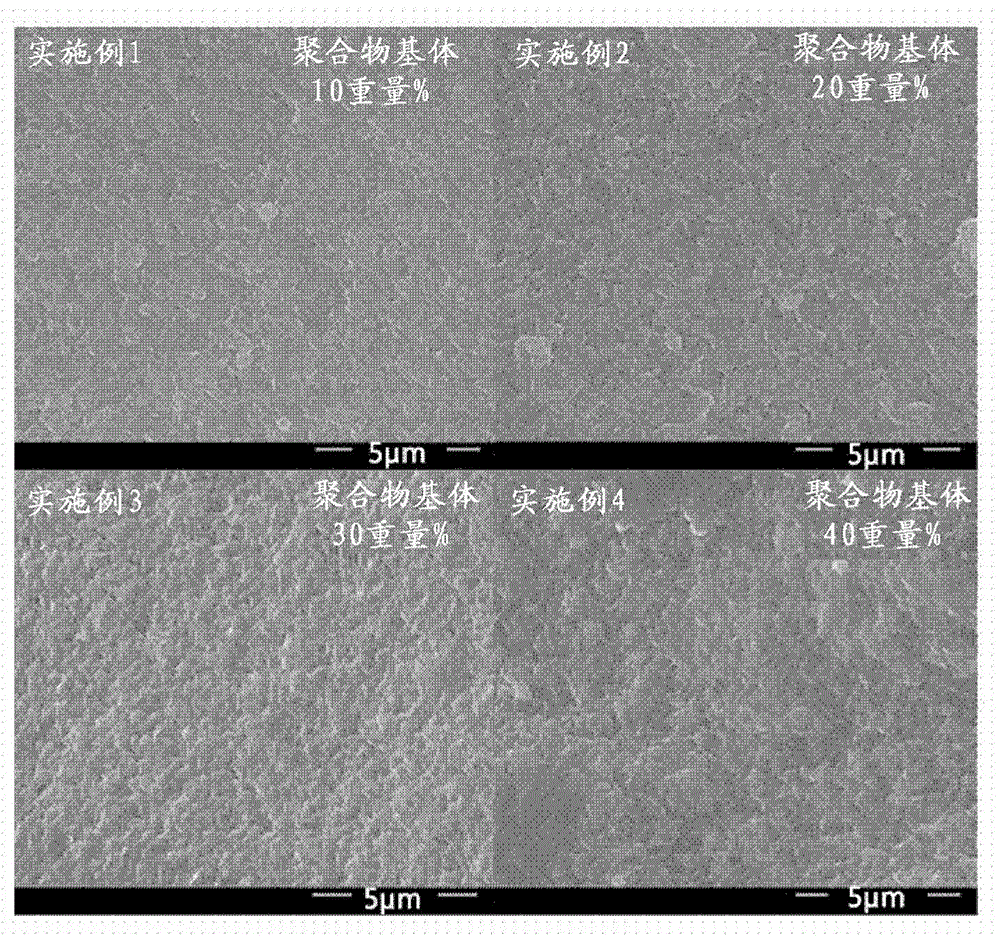

[0070] (1) Preparation of mixed solution

[0071] To 100 parts by weight of acetone as a solvent, 15 parts by weight of a solid mixture containing poly(sodium 4-styrene sulfonate) and poly(vinylidene fluoride-co-hexafluoropropylene) (KYNAR2801, Arkema) and 15 parts by weight of dibutyl phthalate, and then the resulting mixture was subjected to ball milling for 12 hours to obtain a homogeneous mixed solution. The solid mixture contained 10% by weight of poly(sodium 4-styrene sulfonate) and 90% by weight of poly(vinylidene fluoride-co-hexafluoropropylene).

[0072] (2) Production of polymer films

[0073] Twenty hours after the preparation of the mixed solution, the mixed solution was cast on a glass substrate to a thickness of 500 μm by using a doctor blade and allowed to stand at room temperature for 1 hour to obtain a polymer film.

[0074] (3) Production of porous polymer membranes

[0075] The polymer film obtained above was immersed in methanol for at least 12 hours to ...

Embodiment 2

[0079] A gel polymer electrolyte was obtained in the same manner as in Example 1, except that poly(vinylidene fluoride-co-hexa) containing 20% by weight of poly(sodium 4-styrene sulfonate) and 80% by weight of poly(vinylidene fluoride-co-hexa) was used A solid mixture of fluoropropylene) was used instead of a solid mixture comprising 10% by weight of poly(sodium 4-styrene sulfonate) and 90% by weight of poly(vinylidene fluoride-co-hexafluoropropylene).

Embodiment 3

[0081] A gel polymer electrolyte was obtained in the same manner as in Example 1, except that 30% by weight of poly(sodium 4-styrene sulfonate) and 70% by weight of poly(vinylidene fluoride-co-hexa) were used A solid mixture of fluoropropylene) was used instead of a solid mixture comprising 10% by weight of poly(sodium 4-styrene sulfonate) and 90% by weight of poly(vinylidene fluoride-co-hexafluoropropylene).

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com