Composite beehive and manufacturing process thereof

A composite material and beehive technology, which is applied to beehives, beekeeping, synthetic resin layered products, etc., can solve the problems of increasing the risk of bee pilfering in the bee colony, reducing the airtightness of the beehive, increasing the material and cost, and reducing the economic The effect of burden, weight reduction, and production cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

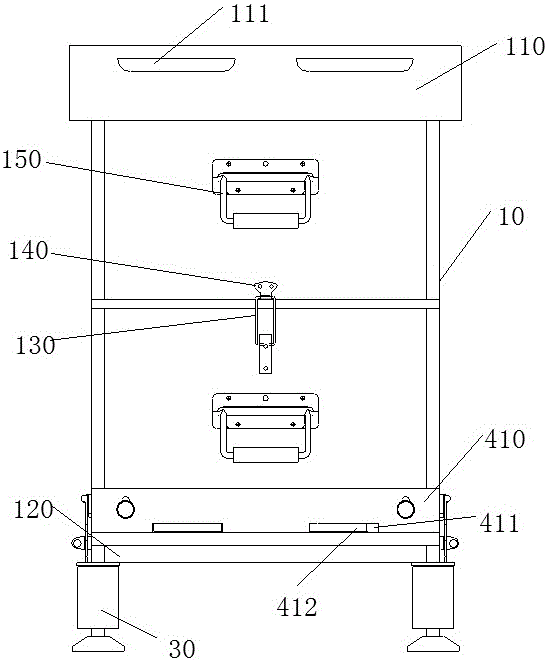

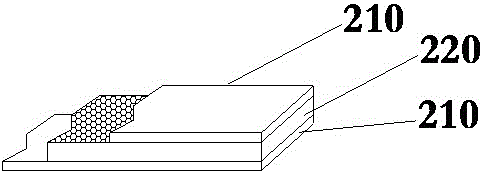

[0029] Such as Figure 1~2 As shown, a composite material beehive includes a plurality of stacked beehive boxes 10 beehive bottom plates and a cover and a top cover 110 arranged on the beehive box 10, the box is composed of box side panels surrounded by four sides, The side plate of the box body includes a pair of outer plates 210 and a core plate 220 arranged between the pair of outer plates. The core plate 220 is a closed-cell foam board formed by polyurethane material. Since the closed-cell foam board is used as the core plate structure, it It is composed of a support structure in the shape of a regular hexagonal frame, so it has good strength. Of course, in practical applications, it can also be made of a material that is chemically stable and does not affect the growth of bees. The outer plate is made of glass fiber reinforced pl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com