Non-pressure-storage type low-temperature gas generator for powder spraying fire extinguisher

A technology of gas generator and gas generating agent, applied in fire rescue and other directions, can solve the problems of high working medium temperature, slow spraying speed, poor fire extinguishing effect, etc., and achieve low chemical reaction temperature, short trigger delay period, and optimized discharge. air effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The embodiments provided below by the accompanying drawings are divided into three parts to further illustrate the present invention.

[0014] The first part, structure composition.

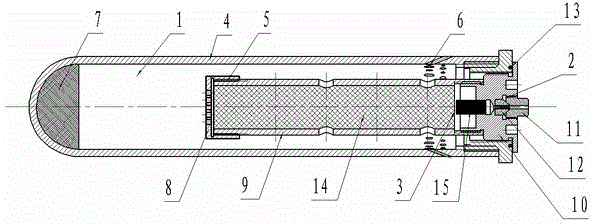

[0015] The gas generator includes: a bladder assembly (1), a base and sealing assembly (2), and a starting assembly (3);

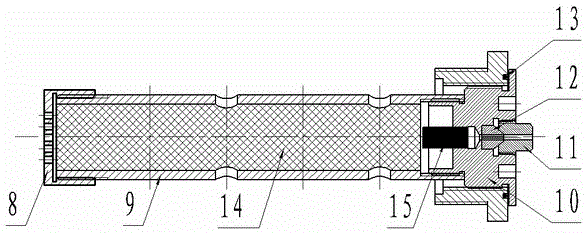

[0016] The bladder assembly (1) includes: an outer tank (4), an inner tank (5), an air vent (6), a moisture-proof agent (7), an inner tank cover (8), and an inner tank barrel (9);

[0017] The base and sealing assembly (2) includes: the base (10), the bladder plug (11), the sealing plug (12), and the gasket (13);

[0018] The starting component (3) includes: a gas generating agent (14) and a starter (15).

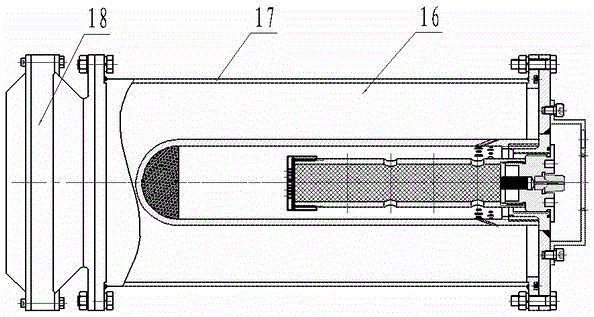

[0019] The powder spray fire extinguisher (16) includes: a fire extinguisher housing (17), and a fire extinguisher nozzle part (18).

[0020] The second part, the structural characteristics of the gas generator.

[0021] In the tank assembly (1), since the moist...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com