A kind of regeneration method of palladium catalyst

A palladium catalyst and solution technology, which is applied in the field of palladium catalyst regeneration, can solve the problems that the activity of the regenerated palladium catalyst cannot reach, the activity of the palladium catalyst cannot reach the activity of the new palladium catalyst, and the regeneration is not thorough enough, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0048] The regeneration method of the palladium catalyst of the present embodiment may further comprise the steps:

[0049] Pre-treatment: Sieve the spent palladium catalyst with a 10-mesh screen to remove particles with a particle size below 2mm to obtain the palladium catalyst to be regenerated.

[0050] Step 1: Weigh 100g of palladium catalyst to be regenerated (FAH-1Q fixed-bed palladium-alumina catalyst scrapped after 6 years of use) into a 500mL beaker, add 180mL of C 10 Aromatic hydrocarbons are soaked, and the aromatic hydrocarbons are separated after soaking for 30 minutes each time, and then the same amount of aromatic hydrocarbons as the first time is added, and soaked in this way for 9 times, and the aromatic hydrocarbons separated in the last time are light yellow;

[0051] Then add 160mL of sodium hydroxide (NaOH) solution with a concentration of 0.1mol / L and a temperature of 30-50°C to the palladium catalyst soaked in the above-mentioned aromatic hydrocarbons fo...

Embodiment 2

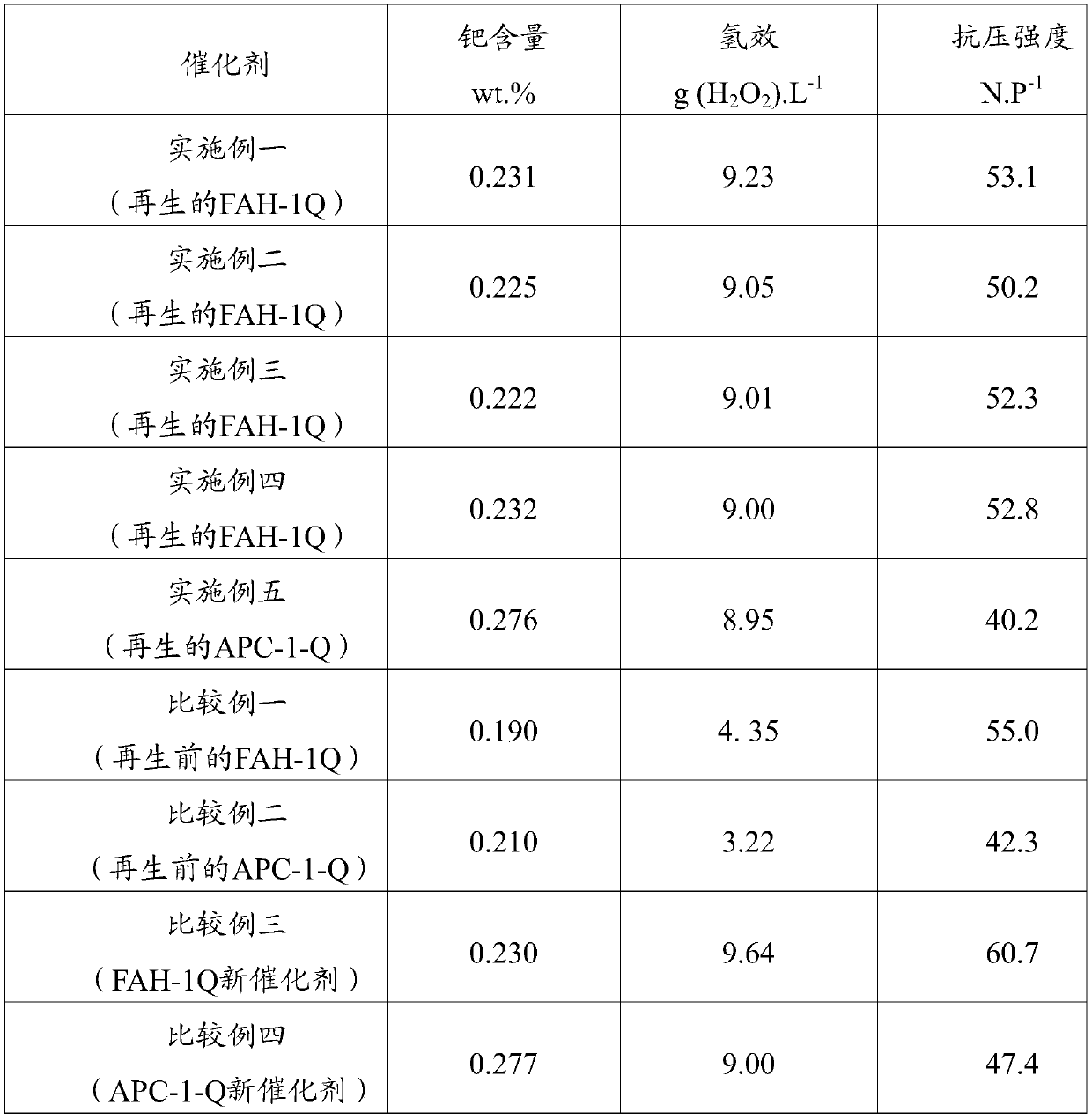

[0065] Repeat the step of embodiment one, just change the mol ratio of sodium chlorate and palladium into 1: 1.5 in wherein step 2, the mol ratio of sodium chlorate and hydrochloric acid is changed into 1: 10, promptly this example sodium chlorate consumption=0.000535614 ÷1.5×106.44÷0.99=0.0383911 (g), wherein 106.44 is the molar mass of sodium chlorate, and 0.99 is the purity of sodium chlorate, considering balance precision, getting 0.0384g) hydrochloric acid consumption is 0.000535614÷1.5×10÷0.012= 0.29756 (mL) is rounded to 0.30mL, the consumption of the sodium hydroxide that is used to regulate catalyst surface pH value still takes by weighing 0.06g in the ratio of embodiment one, the test method of palladium content, activity and compressive strength of catalyst is carried out Example 1 is carried out, and the data are shown in Table 1.

Embodiment 3

[0067] Repeat the step of embodiment one, just used Na when step 3 regulates catalyst surface pH value 2 CO 3 , the ionic equation of the hydrolysis of sodium carbonate is:

[0068] CO 3 2- +H 2 O==HCO 3- +OH -

[0069] HCO 3 - +H 2 OH 2 CO 3 +OH -

[0070] Visible 1 mole of sodium carbonate hydrolysis produces the alkali amount that is close to the alkali amount of 2 moles of sodium hydroxide, and setting sodium carbonate consumption is 0.10% of catalyst weight (equivalent to NaOH consumption is 0.2% of catalyst weight), for this reason Na 2 CO 3 Consumption=30×0.001÷0.995=0.03015(g), actually weigh 0.0302g, 0.995 is the NaOH purity, and the rest are carried out as in Example 1. The test data of palladium content, activity and compressive strength of the catalyst are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| water absorption | aaaaa | aaaaa |

| water absorption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com