Cut-off tools for machining energetic materials

A cutting and cutting tool technology, applied in the direction of tools, cutting inserts, manufacturing tools for lathes, etc., can solve the problems of high safety risk and large material removal, and achieve reduced material removal rate, good cutting effect and safety. sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described in detail below in conjunction with examples, but the implementation of the present invention is not limited thereto.

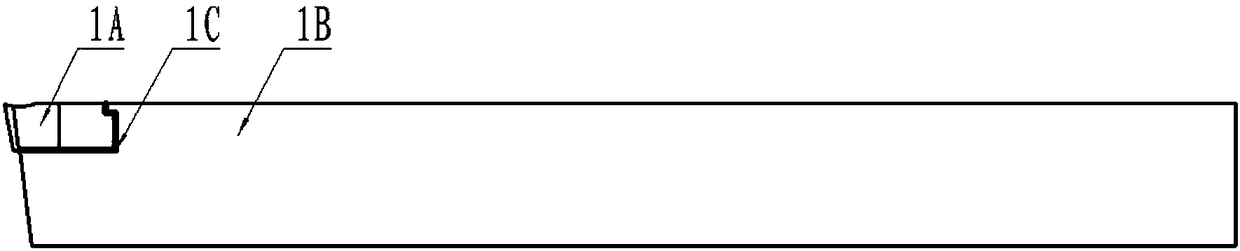

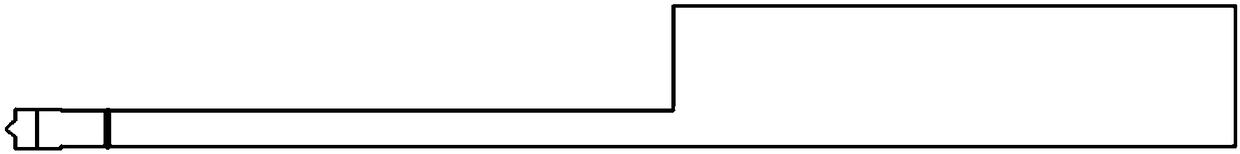

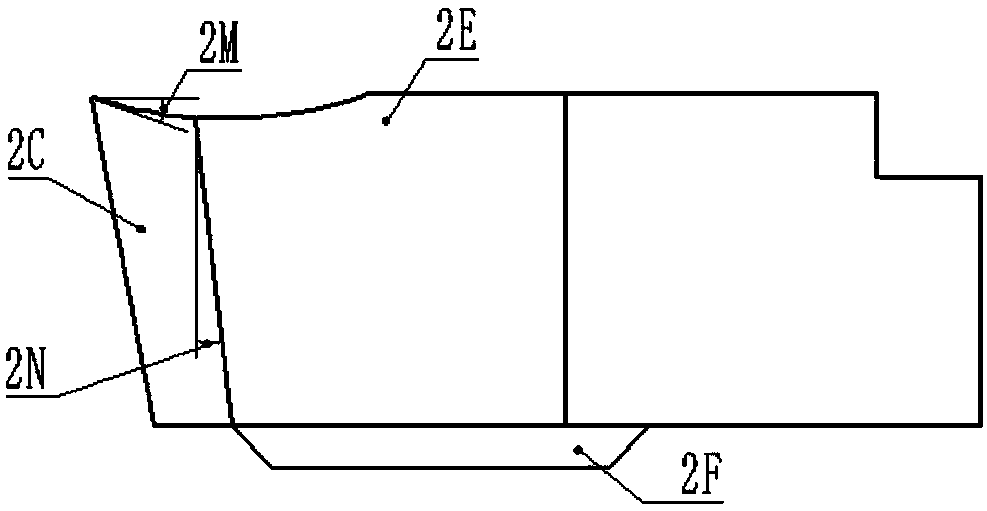

[0030] Such as Figure 1 ~ Figure 5 As shown, a cutting tool for cutting energetic materials is composed of a blade 1A and a shank 1B. The blade 1A is assembled on the positioning groove of the shank 1B by welding, and the bottom of the blade 1A is arranged to facilitate The positioning block 2F fixed by welding is convenient for welding and fixing. The rear end of the blade 1A is also provided with a groove 2G for the mating connection of the cutter bar 1B to increase the rigidity of the cutter. The welding seam 1C of the blade 1A and the cutter bar 1B is polished smooth. The blade structure and geometric angle are optimized for cutting energetic materials.

[0031] The front end of the insert 1A is provided with a major cutting edge of the tool consisting of a triangular cutting edge 2A and a flat edge 2B....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com