Intelligent vibration reduction boring bar and vibration reduction control method

A technology of intelligent vibration reduction and intelligent controller, applied in boring bars and other directions, can solve the problems of lack of automatic vibration reduction adjustment function, difficult maintenance and repair, and large active vibration reduction boring bar system, so as to solve the problem of automatic vibration reduction. Adjustment function, easy maintenance and repair, simple structure effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

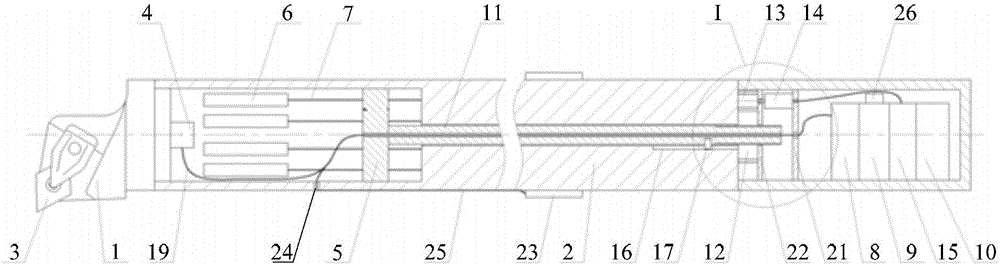

[0041] Embodiment one: combine below figure 1 This embodiment will be described in detail. An intelligent damping boring bar described in this embodiment includes a cutter head 1, a cutter bar 2 and an intelligent controller;

[0042] The cutter head 1 is fixedly arranged on the front end of the cutter bar 2 for clamping the blade 3;

[0043] Inside the cutter bar 2, a cavity is provided near the front end thereof;

[0044] A triaxial acceleration sensor 4, multiple groups of cantilever vibration-absorbing units and a sliding seat 5 are arranged inside the cavity;

[0045] The triaxial acceleration sensor 4 is fixedly arranged on the front end face of the cavity;

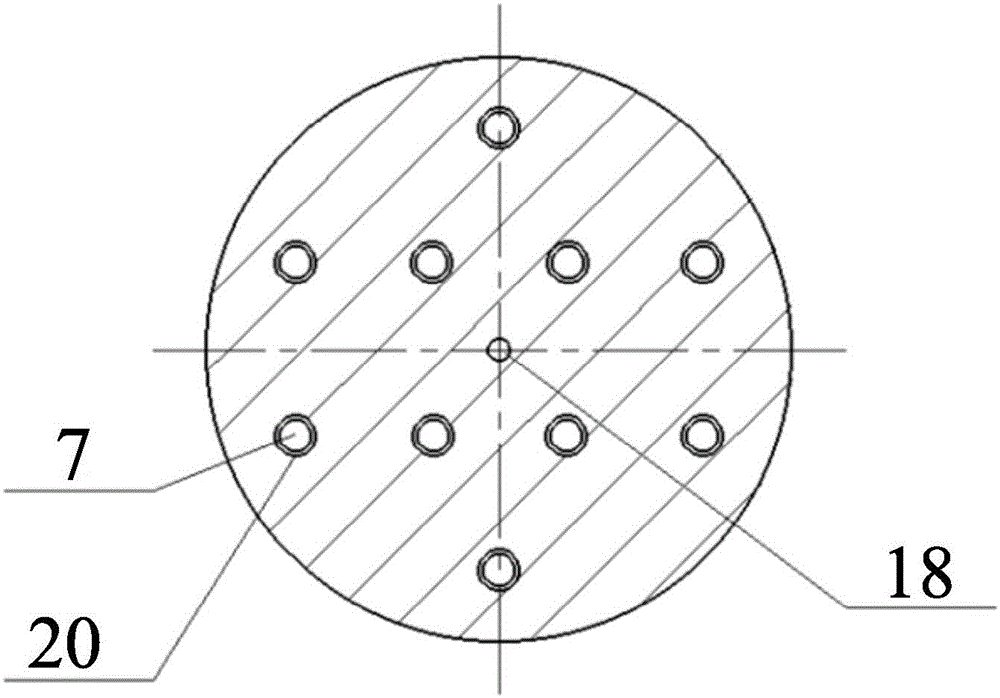

[0046] Each group of cantilever vibration-absorbing units includes a mass block 6 and a cantilever beam 7, one end of the cantilever beam 7 is fixedly connected to the mass block 6, and the other end of the cantilever beam 7 is fixedly arranged on the rear end surface of the cavity. 7 runs through the sliding se...

Embodiment 2

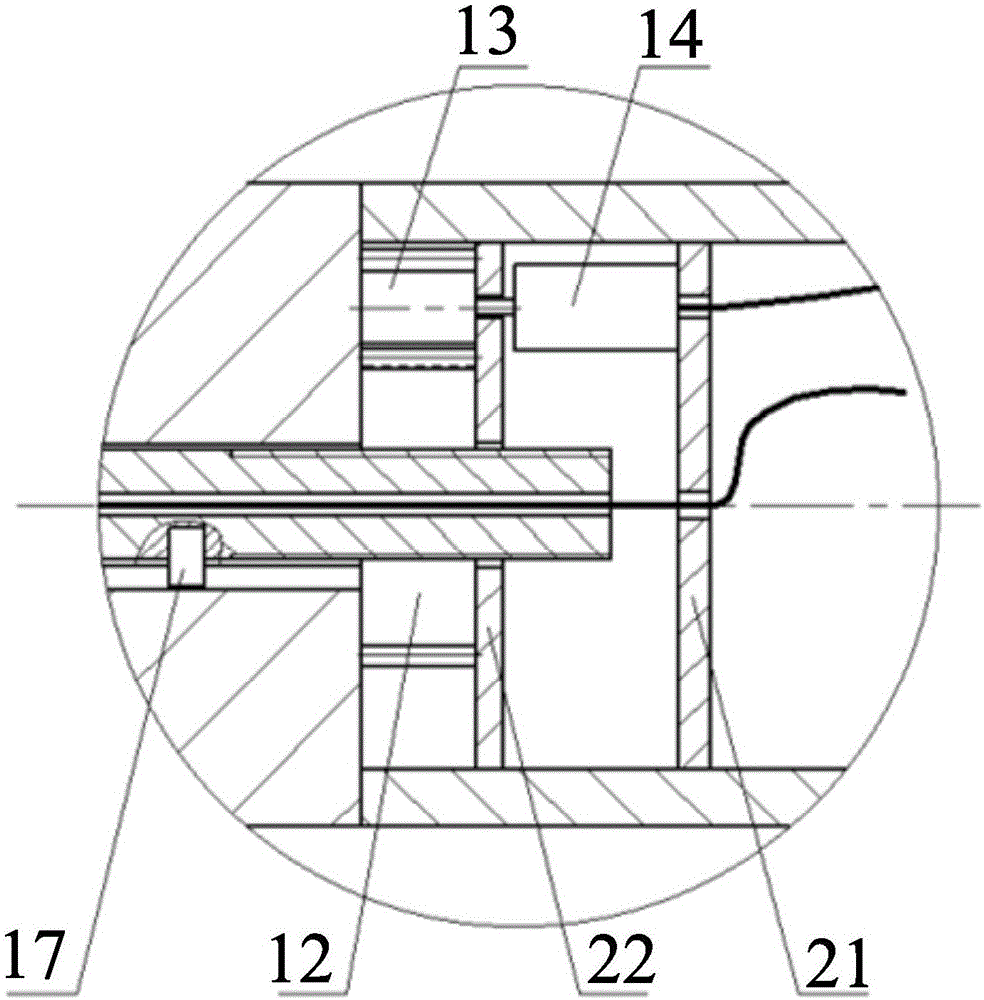

[0054] Embodiment two: combine below figure 1 and figure 2 This embodiment will be described in detail. This embodiment further defines the smart damping boring bar described in the first embodiment. An intelligent damping boring bar described in this embodiment, the transmission unit includes a push rod 11, a first gear 12, a second gear 13, a motor 14 and a driver 15;

[0055] The power supply unit 10 is also used to provide the motor 14 and the driver 15 with the electric energy required for work;

[0056] The data processing unit 9 is used to control the running and stopping of the driver 15;

[0057] The driver 15 is used to drive the motor 14;

[0058] The shaft of the motor 14 is coaxially fixed with the second gear 13;

[0059] The first gear 12 meshes with the second gear 13;

[0060] The first gear 12 is arranged coaxially with the push rod 11, one end of the push rod 11 is threadedly connected with the first gear 12, and the other end of the push rod 11 is fixe...

Embodiment 3

[0062] Embodiment three: the following combination figure 1 This embodiment will be described in detail. This embodiment further defines the smart damping boring bar described in the second embodiment. An intelligent damping boring bar described in this embodiment is also provided with a first through hole inside the tool bar 2, the first through hole communicates with the cavity and the inner space of the housing, and the first through hole communicates with the inner space of the housing. The inner diameter of the through hole is equal to the diameter of the push rod 11, and the push rod 11 located in the first through hole is arranged coaxially with the sliding seat 5;

[0063] In the first through hole, a sliding groove 16 is arranged at a position close to the rear end of the cutter bar 2, and the length direction of the sliding groove 16 is parallel to the axis of the first through hole;

[0064] On the push rod 11, a slide pin 17 is arranged near one end thereof;

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com