Method for laser welding of vibration motor clip and mass block

A vibration motor, laser welding technology, applied in laser welding equipment, welding equipment, metal processing equipment and other directions, can solve the problems of insufficient strength, high melting point, difficult to meet welding strength and appearance requirements, etc., to ensure repeated positioning accuracy and appearance. smooth and flat effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

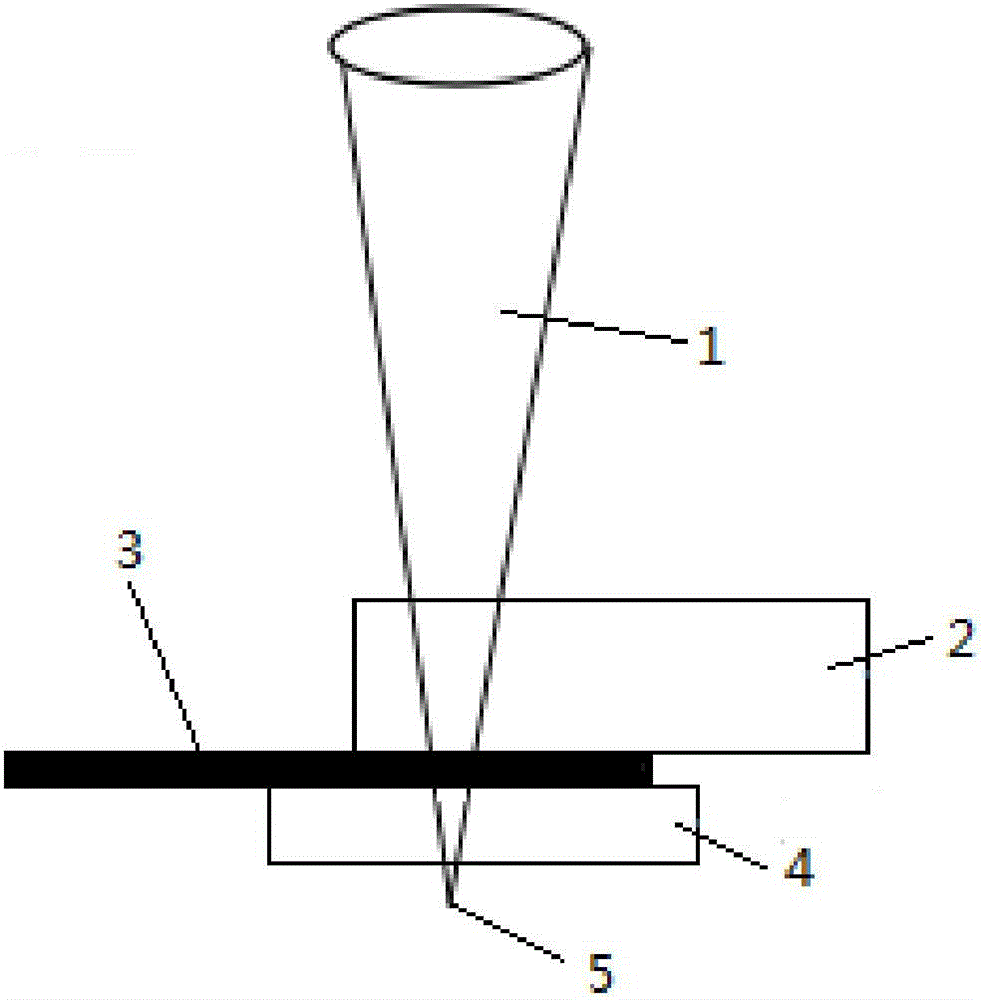

[0019] pass below Figure 1 ~ Figure 3 And the way of enumerating some optional embodiments of the present invention, the technical solution of the present invention (including the preferred technical solution) is described in further detail, and any technical feature and any technical solution in this embodiment do not limit the protection scope of the present invention .

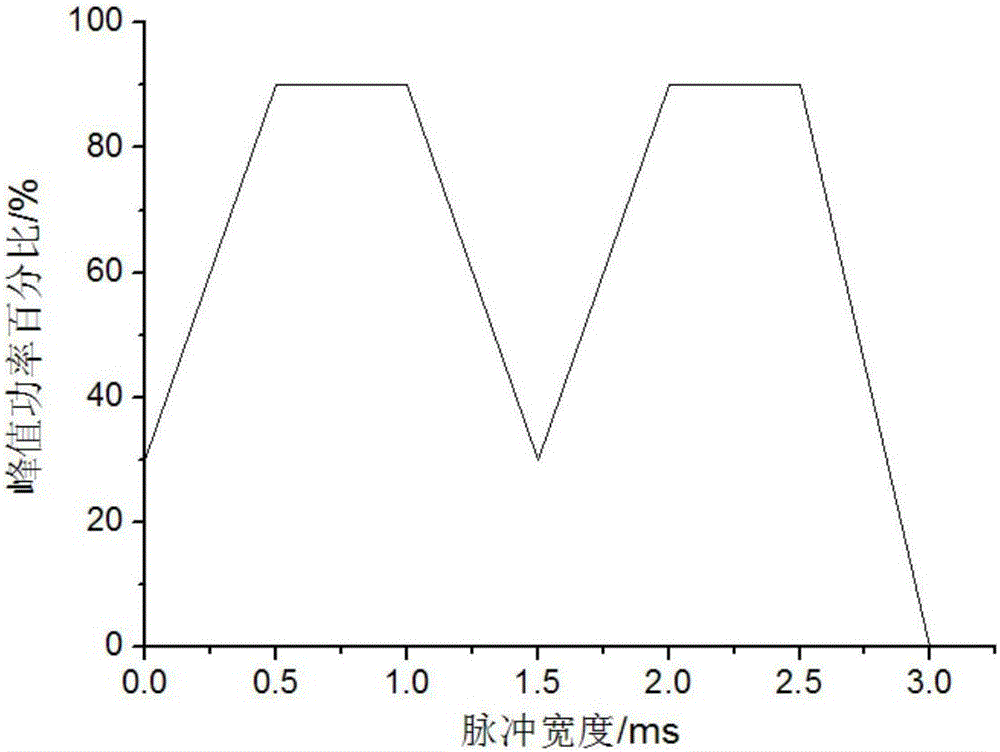

[0020] The laser welding method of the vibrating motor shrapnel and mass block designed by the present invention comprises the following steps:

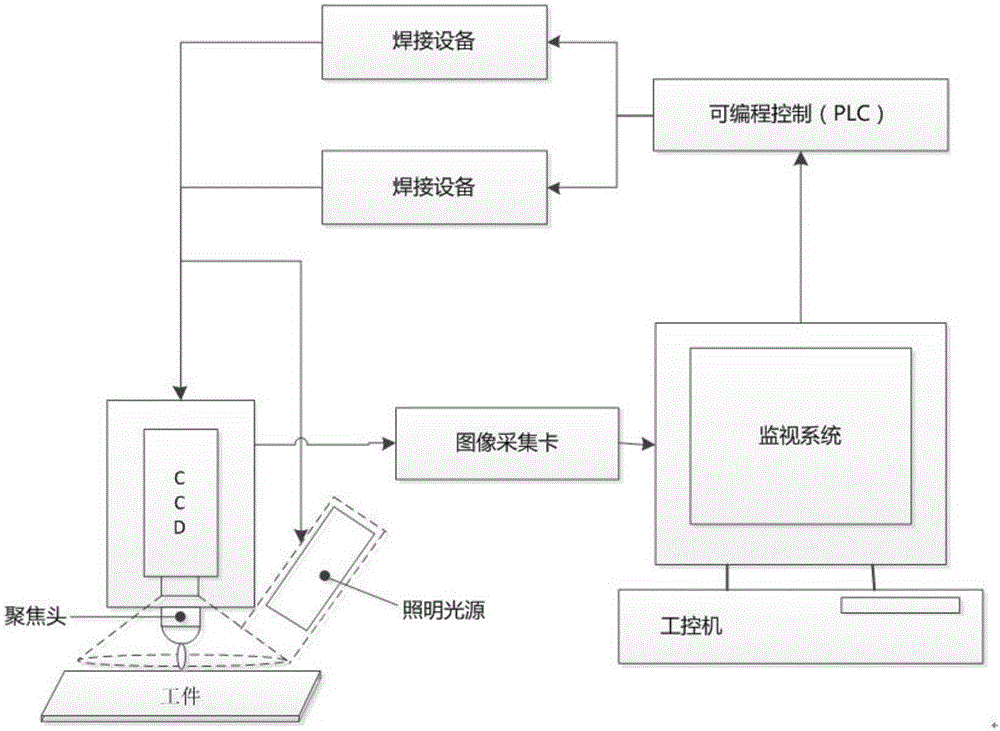

[0021] 1. Use CCD vision to accurately locate the welding position: Use CCD vision camera to identify and take pictures of the feature points of the product, compare the position of the solder joints on the product with the feature points, and form the coordinate values of the required solder joints on the corresponding software , relying on the laser motion control mechanism (such as scanning galvanometer) to transmit the laser to the required welding spot ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com