Footprint sitting electric tricycle

An electric tricycle, pedal sitting technology, applied in the direction of motor vehicles, electric power units, vehicles with inclined bearing motion, etc., can solve the problems of dangerous passengers, damage to the pendulum, uneven force, etc., to improve safety and reliability. Comfort, reduced risk of damage, improved lubrication performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

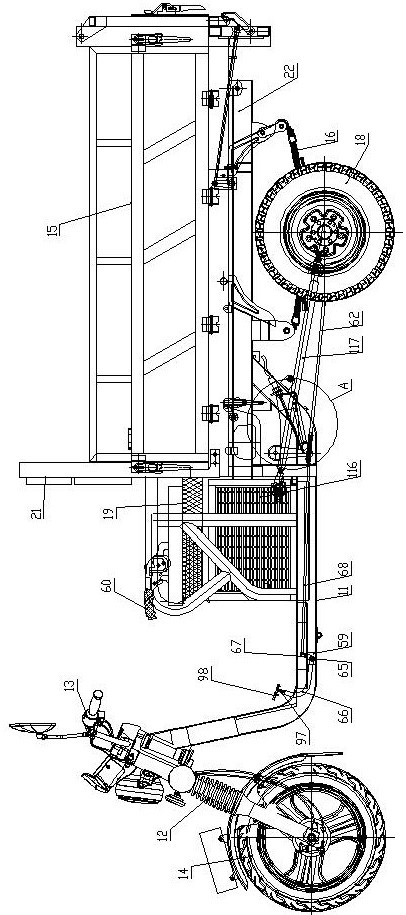

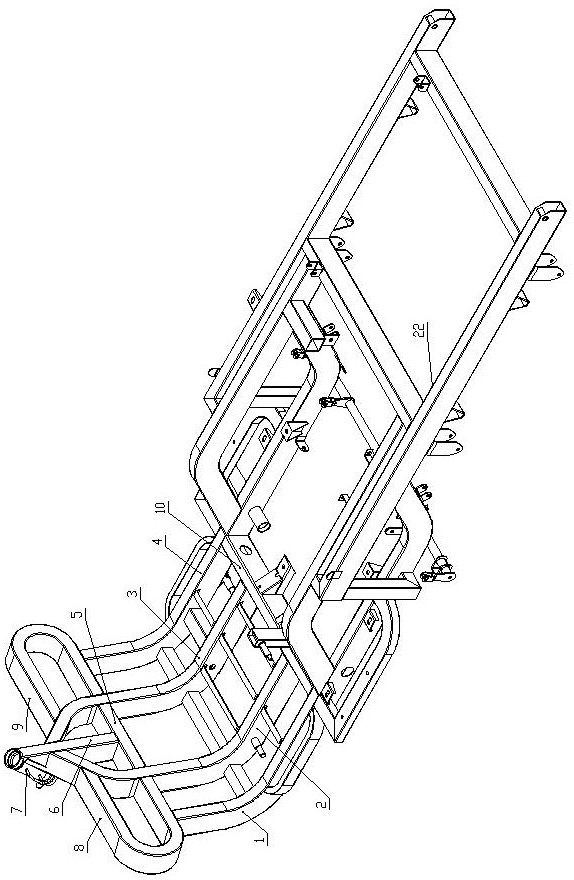

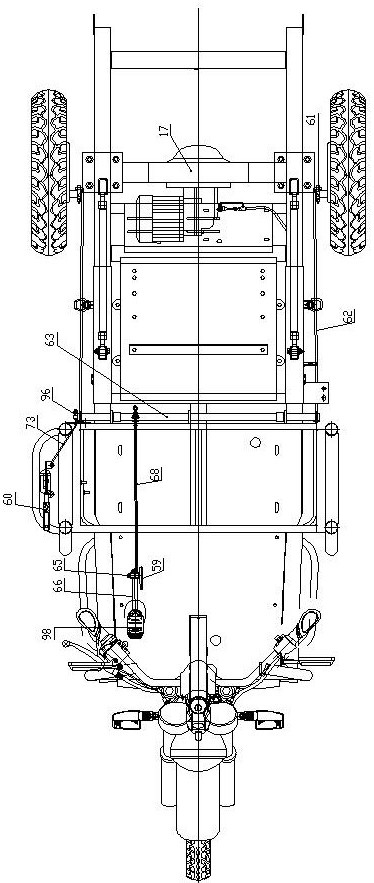

[0048] Such as Figure 1-Figure 13 As shown, the pedal electric tricycle of the present invention comprises a vehicle frame 11, a front fork damping assembly 12 is provided at the front end of the vehicle frame 11, a handlebar 13 is provided at the front fork damping assembly 12, and a front fork damping assembly 12 is provided with a handlebar 13. A front wheel 14 is arranged at the lower end of the vehicle frame 12, a rear carriage 15 is arranged at the top of the rear side of the vehicle frame 11, and a rear axle assembly 17 is connected to the bottom of the rear side of the vehicle frame 11 through a leaf spring damping mechanism 16, and the left and right ends of the rear axle assembly 17 A rear wheel 18 is respectively provided, and the vehicle frame 11 is provided with a driver's seat 19 and a power unit 20 below the driver's seat 19 on the front side of the rear compartment 15. The brake system of the wheel 18; the rear compartment 15 includes a gantry 21, the lower pa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com