Carton palletizer and operating method thereof

A working method, palletizer technology, applied in the field of robotics, to achieve the effect of improving efficiency and precise positioning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] A kind of working method of carton stacker of the present invention comprises the following steps:

[0034] S1: Input the size of the cartons to be palletized, and the system will automatically generate the palletizing graphic and the number of palletizing layers;

[0035] Before the operation starts, input the length, width and height of the packed carton and press the start button, the system will automatically generate the stacking plane graph and the number of stacking layers. The maximum size of carton palletizing is 1800mm (length) X 1800mm (width) X 1700mm (height).

[0036] S2: put the pallet into the pallet station 41, and the pallet adjusting device 2 pushes the pallet to make it center;

[0037] The pallet adjustment device 2 of the carton palletizer pushes the three-sided adjustment baffles 42 to automatically adjust the pallet to the center. Pallet station 41 can accommodate a maximum size of 1800mm (length) X 1800mm (width).

[0038] S3: Put the packed ...

Embodiment 2

[0042] The working method of the carton palletizer includes the following steps:

[0043] S1: Input the size of the cartons to be palletized, and the system will automatically generate the palletizing graphic and the number of palletizing layers;

[0044] S21: The pallet is put in from the front of the pallet station 41, and the pallet adjusting device pushes the baffle plate connected to it to move simultaneously from the two sides and the rear of the pallet station 41 in three directions to squeeze the pallet on the pallet The middle station of station 41;

[0045] S3: Put the packed carton on the connecting pull belt 1 and transport it to the grabbing station 44;

[0046] S41: Stop putting cardboards into the pallet station 41 when it is detected that the pallet station 41 is not loaded with a pallet, or the cartons on the pallet have been stacked to a specified height;

[0047] S42: Detect whether the carton on the connecting pull belt is full, if not, continue to transf...

Embodiment 3

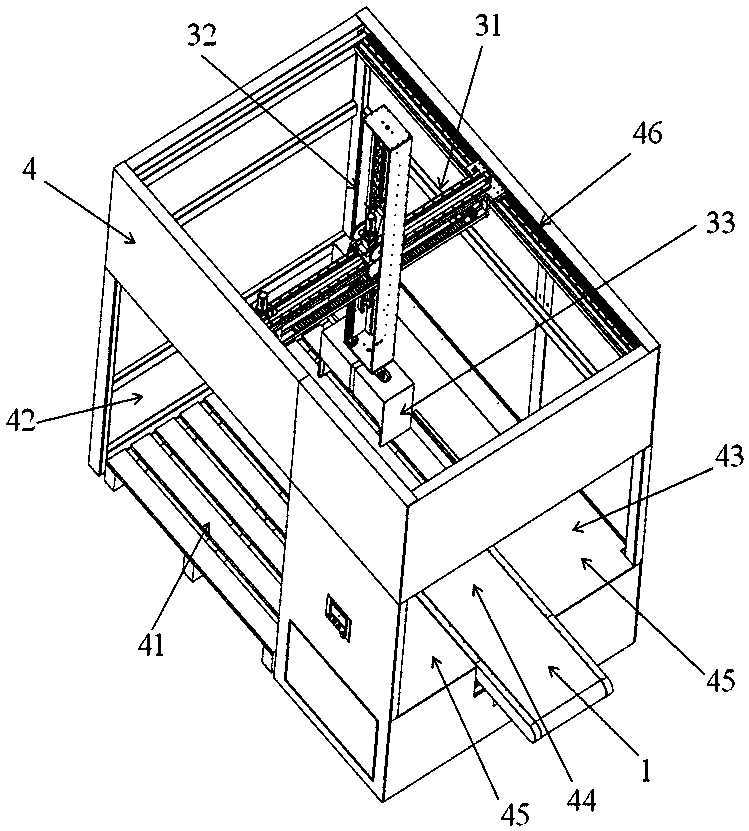

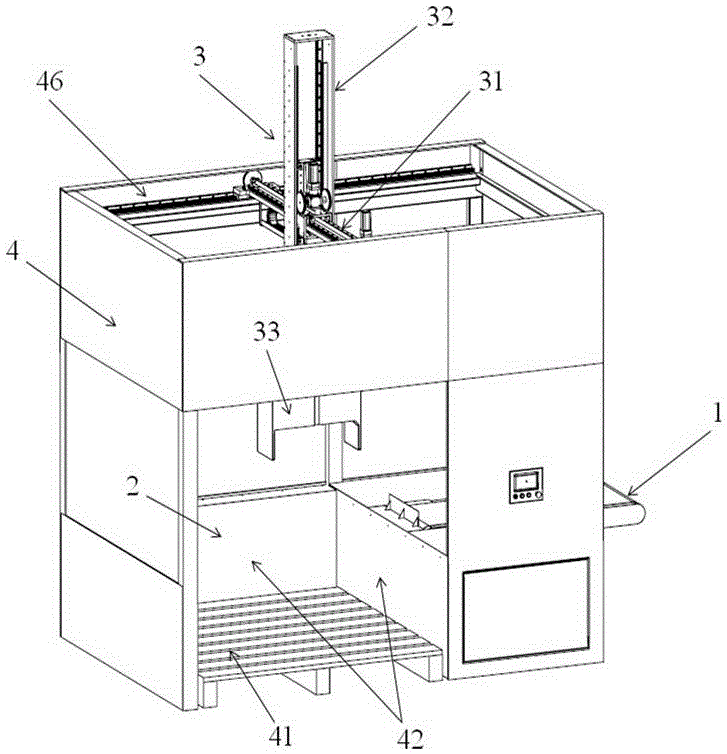

[0061] Such as figure 1 and figure 2 As shown, a carton palletizer of the present invention includes a connecting drawstring 1, a pallet adjusting device 2, a manipulator 3 and a stacking frame 4, and the connecting drawstring 1, the pallet regulating device 2, and the manipulator 3 are respectively connected to the stacking On the frame 4, the stacking frame 4 is provided with a pallet station 41 that is open on one side and blocked on three sides. The stacking frame includes three adjustment baffles 42, and the three adjustment baffles 42 are connected to the pallet adjustment device 2 in turn. The board adjustment device 2 drives the adjustment baffle to move from the two sides and the rear direction of the clamping station 41 to the middle. The three adjusting baffles 42 can be moved simultaneously for positioning, and the pallet is centered in one step.

[0062] Wherein, the stacking frame 4 is provided with a standby platform 43, and the connecting drawstring 1 is con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com