Improved jet aerator

An improved technology of jet aeration, applied in water aeration, chemical instruments and methods, sustainable biological treatment, etc., can solve the problem of small contact area between air bubbles and sewage, unable to meet the requirements of aeration treatment, and the mixing of air and water is not special Sufficient and other issues to achieve the effect of improving the oxygen melting effect, improving the transfer efficiency, and improving the aeration effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

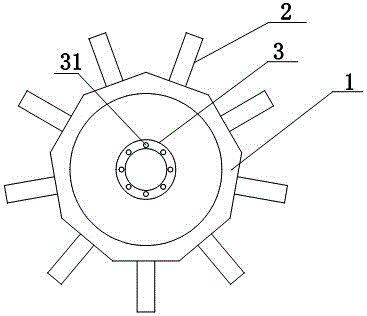

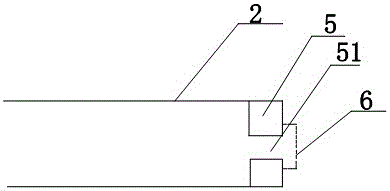

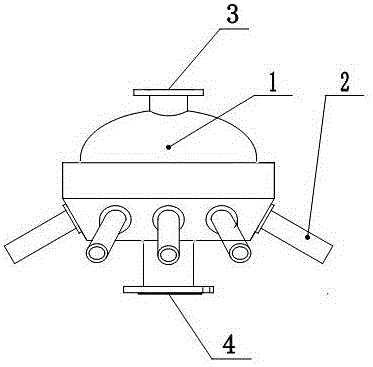

[0015] Such as figure 1 , figure 2 and image 3 As shown, the present invention provides an improved jet aerator, which includes a casing 1 and jet aeration heads 2 evenly arranged on the surface of the casing 1. The top and bottom ends of the casing 1 are respectively provided with air inlet Inlet 3 and water inlet 4, a flow control block 5 is arranged at the water outlet end in the jet aerator head 2, and a converging flow outlet hole 51 is arranged on the flow control block 5, and the water outlet of the converging flow outlet hole 51 The end is provided with a stainless steel mesh 6, and the stainless steel mesh 6 is covered outside the water outlet end of the water gathering outlet 51, and the water gathering outlet 51 is located at the center of the flow control block 5, and the flow control block 5 is connected with the jet aeration The head 2 is integrally formed, and the air inlet 3 and the water inlet 4 are fixed on the housing 1 by several fixing bolts 31 .

Embodiment 2

[0017] Such as figure 1 , figure 2 and image 3 As shown, the sewage enters the housing 1 from the water inlet 4, and the air enters the housing 1 from the air inlet 3. The air and sewage in the housing 1 are fully mixed and fused to form air-water mixed bubbles, and the air-water mixture The air bubbles enter the jet aerator head 2 and are sprayed out through the outlet hole 51 of the flow control block 5. The sprayed air-water mixed air bubbles are divided into smaller air bubbles by the stainless steel mesh 6, and the air bubbles enter the sewage Fully contact with sewage to achieve aeration effect.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com