An energy-saving film for high ultraviolet reflection of aircraft windshield glass and its preparation method

A windshield, high-ultraviolet technology, applied in the field of thin film manufacturing, can solve the problems of not taking into account ultraviolet rays, energy saving, lack, etc., and achieve the effects of improving ultraviolet reflection performance, reducing pressure, and small temperature changes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

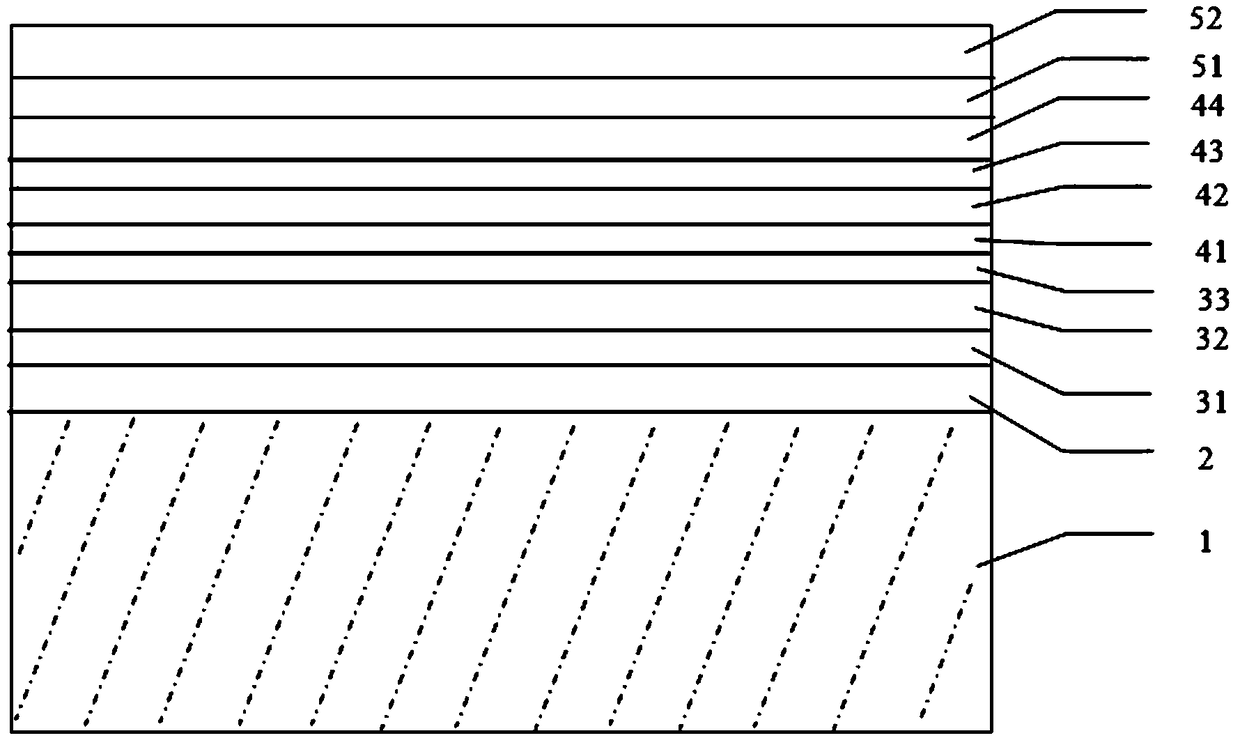

[0029] A kind of energy-saving film for high ultraviolet reflection of aircraft windshield of the present invention, said energy-saving film for high ultraviolet reflection of aircraft windshield comprises windshield glass substrate, inner silicon oxide layer 2, high ultraviolet reflection layer, energy-saving layer and The outer silicon oxide layer 5, on the windshield glass substrate from the inside to the outside direction is an inner silicon oxide layer 2, a high ultraviolet reflection layer, an energy saving layer and an outer silicon oxide layer 5.

[0030] The inner and outer silicon oxide layers are used to protect the overall film system and improve the service life and wear resistance of the film layer.

[0031] The film thickness of the inner silicon oxide layer 2 is 18nm; the high ultraviolet reflective layer is sequentially composed of a first titanium oxide layer 31, a cerium oxide layer 32 and a second titanium oxide layer 33 from the inside to the outside, and t...

Embodiment 2

[0042] The difference between embodiment 2 and embodiment 1 is: a kind of energy-saving film for high ultraviolet reflection of aircraft windshield of the present invention, described energy-saving film for high ultraviolet reflection of aircraft windshield comprises windshield glass substrate, inner silicon oxide layer, a high ultraviolet reflection layer, an energy saving layer and an outer silicon oxide layer, and the windshield glass substrate is sequentially composed of an inner silicon oxide layer, a high ultraviolet reflection layer, an energy saving layer and an outer silicon oxide layer from the inside to the outside.

[0043] The film thickness of the inner silicon oxide layer 2 is 21nm; the high ultraviolet reflective layer is sequentially composed of a first titanium oxide layer 31, a cerium oxide layer 32 and a second titanium oxide layer 33 from the inside to the outside, and the first titanium oxide layer 31 The film thickness is 15 nm, the film thickness of the ...

Embodiment 3

[0052] The difference between embodiment 3 and embodiment 1 is: a kind of energy-saving film for high ultraviolet reflection of aircraft windshield of the present invention, described energy-saving film for high ultraviolet reflection of aircraft windshield comprises windshield glass substrate, inner silicon oxide layer, a high ultraviolet reflection layer, an energy saving layer and an outer silicon oxide layer, and the windshield glass substrate is sequentially composed of an inner silicon oxide layer, a high ultraviolet reflection layer, an energy saving layer and an outer silicon oxide layer from the inside to the outside.

[0053] The film thickness of the inner silicon oxide layer 2 is 23nm; the high ultraviolet reflective layer is sequentially composed of a first titanium oxide layer 31, a cerium oxide layer 32 and a second titanium oxide layer 33 from the inside to the outside, and the first titanium oxide layer 31 The film thickness is 25 nm, the film thickness of the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com