Intelligent selective sunlight transmission and reflection coating and preparation method thereof

A reflective coating and selective technology, applied in the coating, metal material coating process, sputtering coating, etc., can solve the problems of decreased solar light regulation rate, unfavorable comprehensive performance, complex process, etc., and achieve improved thermal stability Sex and interface binding force, improve thermal stability and work reliability, good thermal stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

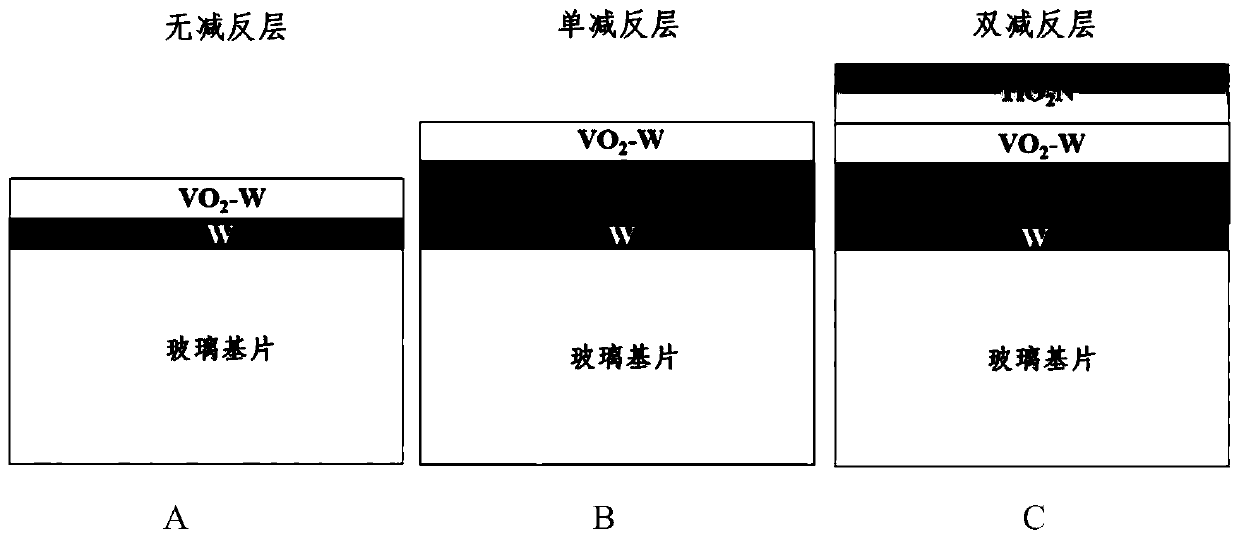

Embodiment 1

[0035] The background vacuum is 3.0×10 -5 Pa, the working pressure is 1.0Pa, high-purity Ar gas is used as the ion source, the flow rate is 20sccm, O 2 and N 2 gas as a reaction gas.

[0036] First, a metal W film with a thickness of 3nm was deposited on the quartz glass, the sputtering power was 200W, as a diffusion barrier layer, and the substrate temperature was room temperature.

[0037] Inner anti-reflection layer TiO 2 (rutile phase) deposition, TiO deposition by RF reactive sputtering 2 Layer, pass the reaction gas O 2 gas, the substrate temperature is 200°C, the sputtering power is 180W, O 2 The partial pressure is 0.15Pa, and the thickness is 10nm.

[0038] Main dimming layer VO 2 -W, VO deposited by RF co-sputtering 2 -W floor, VO 2 Co-sputtering with W double target, the sputtering power is 180W and 180W respectively, the substrate temperature is 200℃, and the layer thickness is controlled at 20nm. The W molar content is 0.3%.

[0039] Outer anti-reflecti...

Embodiment 2

[0042] The background vacuum is 3.0×10 -5 Pa, the working pressure is 1.0Pa, high-purity Ar gas is used as the ion source, the flow rate is 20sccm, O 2 and N 2 gas as a reaction gas.

[0043] First, a metal W film with a thickness of 5nm was deposited on the quartz glass, the sputtering power was 500W, as a diffusion barrier layer, and the substrate temperature was room temperature.

[0044] Inner anti-reflection layer TiO 2 (rutile phase) deposition, TiO deposition by RF reactive sputtering 2 Layer, pass the reaction gas O 2 gas, the substrate temperature is 300°C, the sputtering power is 250W, O 2 The partial pressure is 0.15Pa, and the thickness is 20nm.

[0045] Main dimming layer VO 2 -W, VO deposited by RF co-sputtering 2 -W floor, VO 2 Co-sputtering with W double target, the sputtering power is 250W and 250W respectively, the substrate temperature is 350℃, and the layer thickness is controlled at 30nm. The W molar content is 2%.

[0046] Outer anti-reflection...

Embodiment 3

[0049] The background vacuum is 3.0×10 -5 Pa, the working pressure is 1.0Pa, high-purity Ar gas is used as the ion source, the flow rate is 20sccm, O 2 and N 2 gas as a reaction gas.

[0050] First, a metal W film with a thickness of 8nm was deposited on the quartz glass, the sputtering power was 200W, as a diffusion barrier layer, and the substrate temperature was room temperature.

[0051] Inner anti-reflection layer TiO 2 (rutile phase) deposition, TiO deposition by RF reactive sputtering 2 Layer, pass the reaction gas O 2 gas, the substrate temperature is 300°C, the sputtering power is 250W, O 2 The partial pressure is 0.15Pa, and the thickness is 40nm.

[0052] Main dimming layer VO 2 -W, VO deposited by RF co-sputtering 2 -W floor, VO 2 Co-sputtering with W double target, the sputtering power is 300W and 300W respectively, the substrate temperature is 350℃, and the layer thickness is controlled at 30nm. The W molar content is 2%.

[0053] Outer anti-reflection...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com