Biodegradable resin composition and manufacture method of resin composition and molded product

A resin composition and biodegradable technology, applied in the field of biodegradable compositions, can solve problems such as insufficient adhesion, difficulty in obtaining mechanical strength, affinity and even insufficient adaptability, and achieve the effect of improving design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

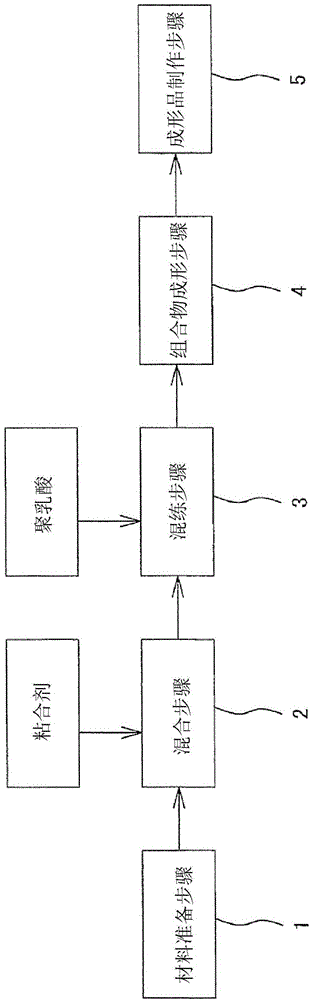

Method used

Image

Examples

Embodiment 13

[0089] In Example 13, as an attempt to reduce the specific gravity of the product, 5% of zeolite was added, so a reduction in the specific gravity was confirmed.

Embodiment 14

[0090] In Example 14, as an attempt to improve the impact strength of the product, 5% rubber powder was added, and the effect can be seen. In the present invention, not only the above three points but also various additives can be added for function improvement.

[0091] In Comparative Example No. 21, normal particles were not obtained because there were too many bamboo materials. In Comparative Example No. 22, the particle shape was maintained, but uneven distribution was observed as a result of longitudinal cross-sectional observation. In Comparative Example No. 23, it was normal as particles.

[0092] Samples for dumbbell tests and Charpy impact tests were prepared using the pellets produced using the above-mentioned samples, using an injection molding machine. The forming temperature was set at 170°C, and the mold temperature was set at 40°C.

[0093] Table 2 shows the results of No. 5(II) and No. 3 in comparison with each value of the polypropylene resin (hereinafter a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com