Segmented carbon-ceramic composite material rotor for purifying aluminum melt and preparation method thereof

A composite material and segmented technology, which is applied in the field of segmented carbon-ceramic composite material rotors for aluminum melt purification and its preparation, can solve the problems of graphite rotors such as low service life, poor strength and toughness, and weak oxidation resistance , to achieve excellent oxidation resistance and corrosion resistance, reduce processing costs and improve production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

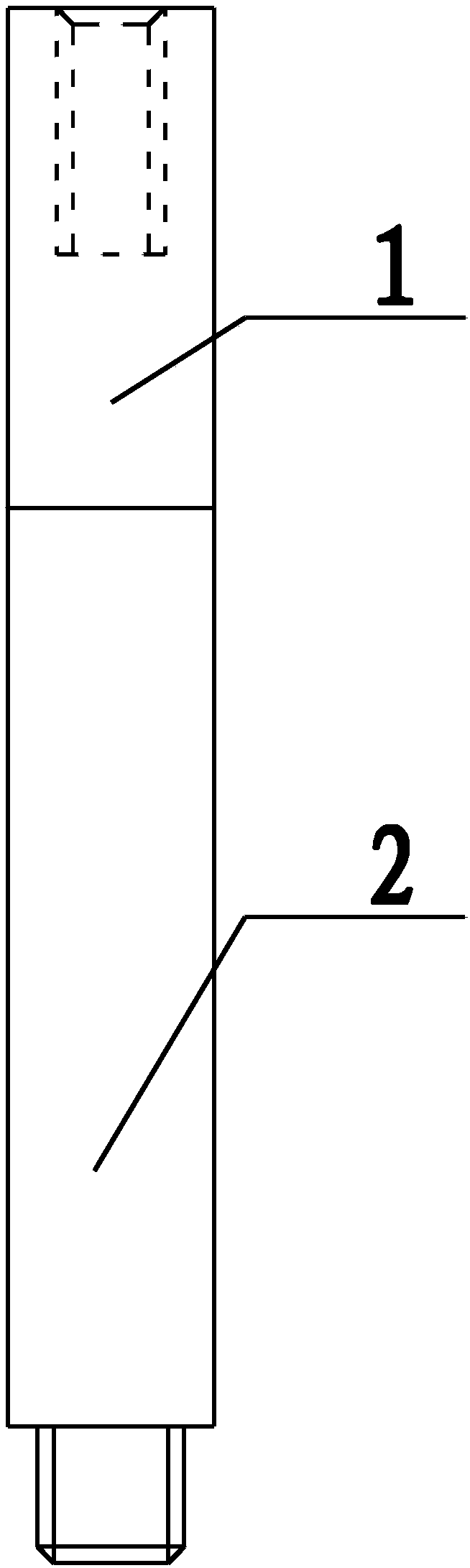

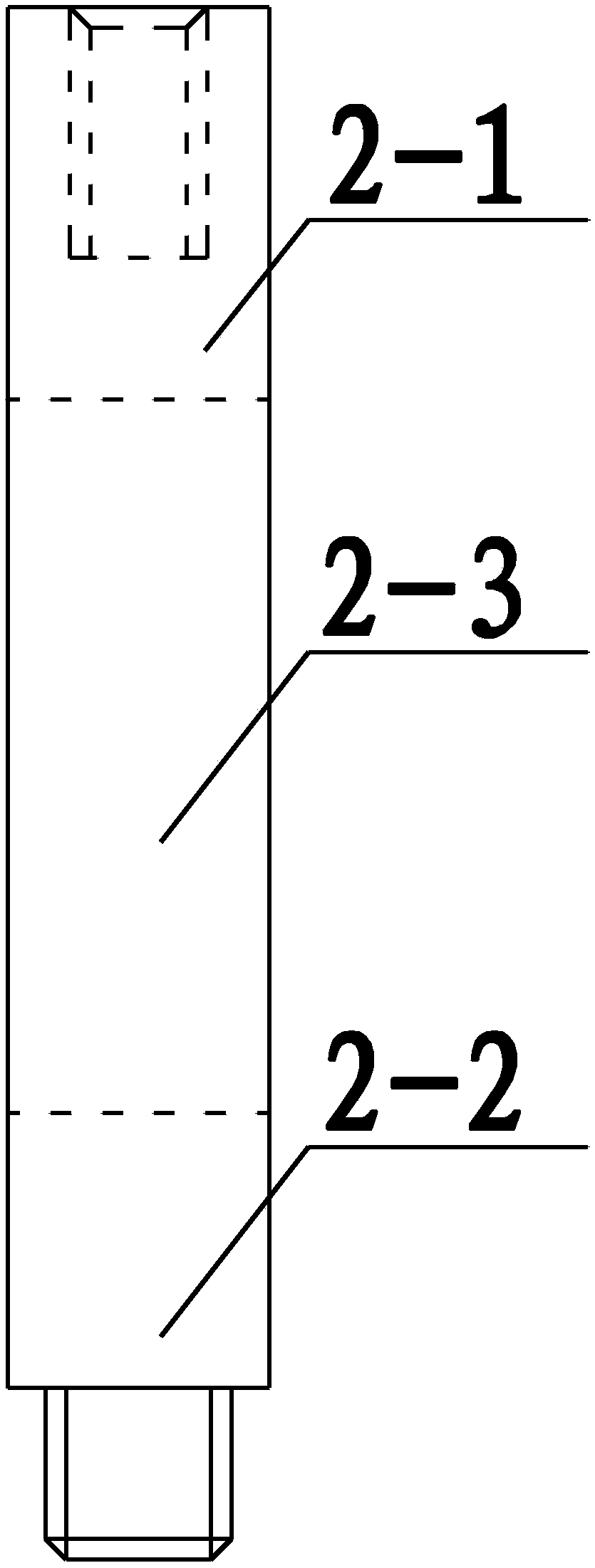

[0037] Such as figure 1 with figure 2 As shown, the segmented carbon-ceramic composite rotor for aluminum melt purification in this embodiment includes a graphite segment 1 and a composite segment 2, and the graphite segment 1 and the composite segment 2 are threaded; the composite segment 2 Including C / C composite material upper section 2-1 and C / C composite material lower section 2-2, and C / C-SiC located between C / C composite material upper section 2-1 and C / C composite material lower section 2-2 The composite material section 2-3, the C / C composite material upper section 2-1, the C / C-SiC composite material section 2-3 and the C / C composite material lower section 2-2 are of an integrated structure.

[0038] In this embodiment, there is one graphite segment 1 , and the graphite segment 1 is located above the composite segment 2 .

[0039] In this embodiment, the graphite section 1 is provided with external threads, and the composite section 2 is provided with internal thre...

Embodiment 2

[0047] Such as Figure 4 with Figure 5 As shown, the segmented carbon-ceramic composite rotor for aluminum melt purification in this embodiment includes a graphite segment 1 and a composite segment 2, and the graphite segment 1 and the composite segment 2 are threaded; the composite segment 2 Including C / C composite material upper section 2-1 and C / C composite material lower section 2-2, and C / C-SiC located between C / C composite material upper section 2-1 and C / C composite material lower section 2-2 The composite material section 2-3, the C / C composite material upper section 2-1, the C / C-SiC composite material section 2-3 and the C / C composite material lower section 2-2 are of an integrated structure.

[0048] In this embodiment, the number of the graphite segments 1 is two, and the composite segment 2 is located between the two graphite segments 1 .

[0049] In this embodiment, the graphite section 1 is provided with external threads, and the composite section 2 is provide...

Embodiment 3

[0057] Such as Figure 4 with Figure 5 As shown, the structure of the segmented carbon-ceramic composite material rotor for purifying aluminum melt in this embodiment is the same as that in Embodiment 2.

[0058] The preparation method of the segmented carbon-ceramic composite rotor of this embodiment includes the following steps:

[0059] Step 1. According to the shape and performance requirements of the carbon-ceramic composite rotor to be prepared, use carbon fiber, carbon cloth and net tire to make a density of 0.50g / cm by conventional methods. 3 carbon fiber preform, and then the carbon fiber preform is densified to obtain a density of 1.40g / cm 3 C / C composite materials;

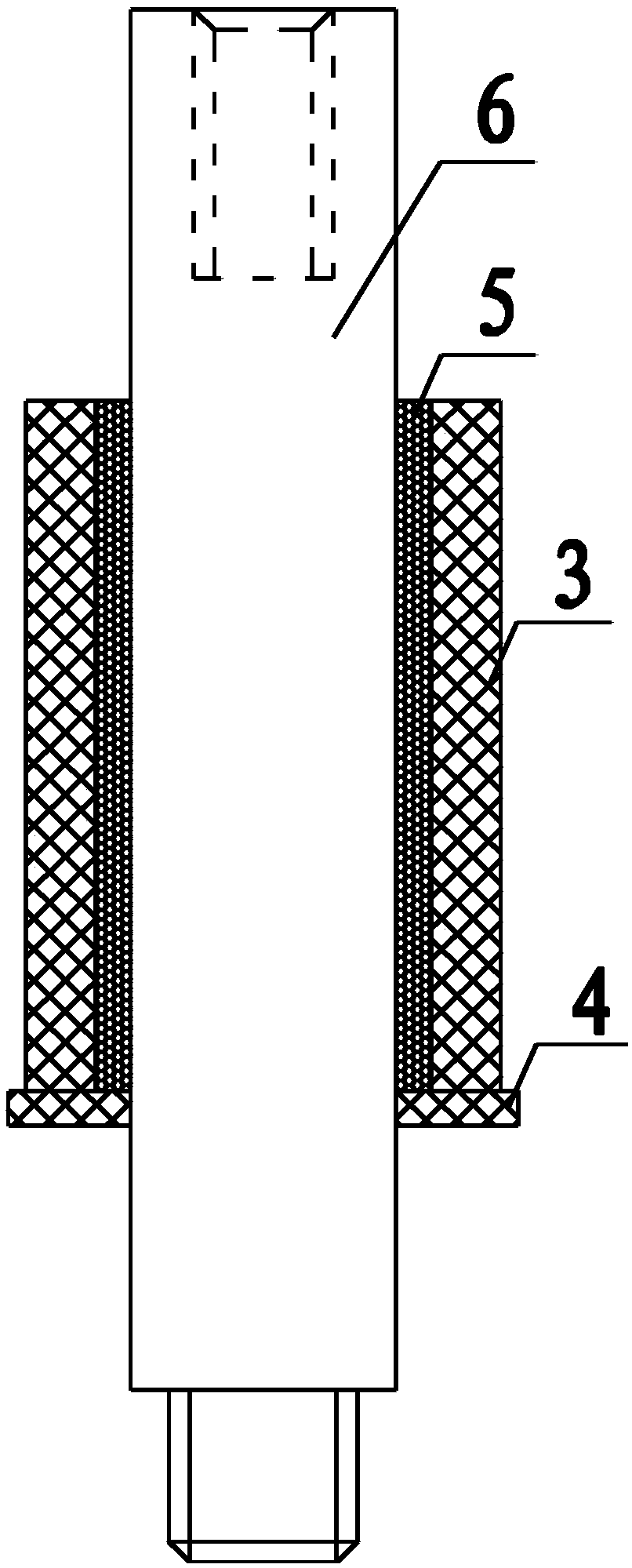

[0060] Step 2, machining the C / C composite material described in step 1 into a C / C composite rod 6 with a diameter of 200 mm and a height of 500 mm;

[0061] Step 3, the graphite tooling is set on the middle section of the C / C composite material rod 6 described in step 2, the graphite tooling inclu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com