Method for enhancing softness of paper for daily use

A tissue paper and softness technology, applied in the post-treatment and modification of cellulose pulp, can solve the problems that are not conducive to human health and environmental quality, and affect the strength of paper, so as to be beneficial to human health and improve the degree of smoothness , Improve the effect of soft performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] A method for improving the softness of household paper (toilet paper), comprising the steps of:

[0020] 1) beating bleached softwood kraft pulp to a beating degree of 30°SR; obtaining fiber pulp;

[0021] 2) Get six parts of equal mass fiber slurry, add water to adjust the mass concentration of fiber slurry to 5%, adjust pH to 6.0, add different amounts of cellulase in six parts, so that the mass fraction of cellulase is respectively 0%, 0.2%, 0.4%, 0.6%, 0.8%, 1.0%, at a temperature of 50°C, act on cellulase for 60 minutes;

[0022] 3) Dilute the material obtained in step 2) with water to a mass concentration of 1%, and make 20g / m with a slicer 2 tissue paper (toilet paper). See Table 1, 2, 3.

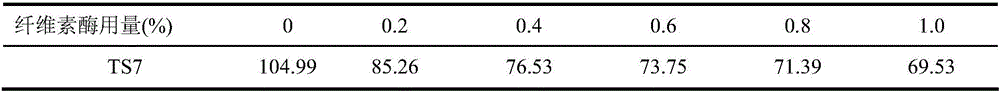

[0023] Table 1 Effect of cellulase dosage on softening properties of bleached softwood kraft pulp

[0024]

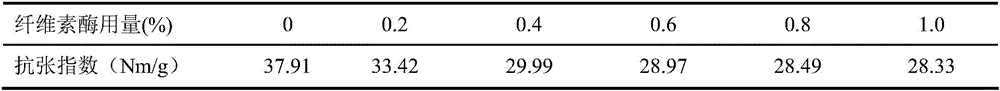

[0025] Table 2 Effect of cellulase dosage on strength properties of bleached softwood kraft pulp

[0026]

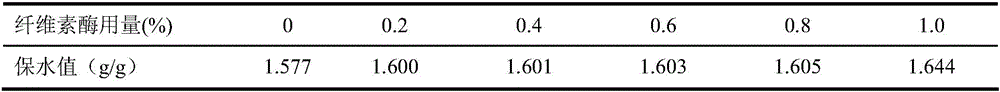

[0027] Table 3 Effect of cellulase dosage on wate...

Embodiment 2

[0030] A method for improving the softness of household paper (toilet paper), comprising the steps of:

[0031] 1) beating bleached hardwood kraft pulp to a beating degree of 35°SR; obtaining fiber pulp;

[0032] 2) Get six parts of equal mass fiber slurry, add water to adjust the mass concentration of fiber slurry to 10%, adjust pH to 5.5, add different amounts of cellulase in six parts, so that the mass fraction of cellulase is respectively 0%, 0.2%, 0.4%, 0.6%, 0.8%, 1.0%, at 60°C, act on cellulase for 30 minutes;

[0033] 3) Dilute the material obtained in step 2) with water to a mass concentration of 1%, and make 30g / m with a slicer 2 tissue paper (toilet paper). See Table 4, 5, 6.

[0034] Table 4 Effect of cellulase dosage on softening properties of bleached hardwood kraft pulp

[0035]

[0036] Table 5 Effect of cellulase dosage on strength properties of bleached hardwood kraft pulp

[0037]

[0038] Table 6 Effect of cellulase dosage on water retention valu...

Embodiment 3

[0041] A method for improving the softness of household paper (facial tissue), comprising the steps of:

[0042] 1) beating the mechanical pulp to a beating degree of 25°SR; obtaining fiber pulp;

[0043] 2) Get six parts of equal mass fiber slurry, add water to adjust the mass concentration of fiber slurry to 3%, adjust pH to 5.5, add different amounts of cellulase in six parts, so that the mass fraction of cellulase is respectively 0%, 0.2%, 0.4%, 0.6%, 0.8%, 1.0%, at 40°C, act on cellulase for 120 minutes;

[0044] 3) Dilute the material obtained in step 2) with water to a mass concentration of 1%, and use a paper machine to make 30g / m 2 tissue paper (facial tissue). See Table 7, 8, 9.

[0045] Table 7 Effect of cellulase dosage on mechanical pulp softness

[0046]

[0047] Table 8 Effect of cellulase dosage on mechanical pulp strength properties

[0048]

[0049] Table 9 Effect of cellulase dosage on water retention value of mechanical pulp

[0050]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com