Transient negative pressure unbalanced drilling device and method

An underbalanced drilling and negative pressure technology, which is applied to drilling equipment and methods, drilling equipment, earthwork drilling and production, etc., can solve the problems of reservoir pollution and low mechanical penetration rate, so as to protect the reservoir and increase the mechanical penetration rate , low cost of manufacturing and use and maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

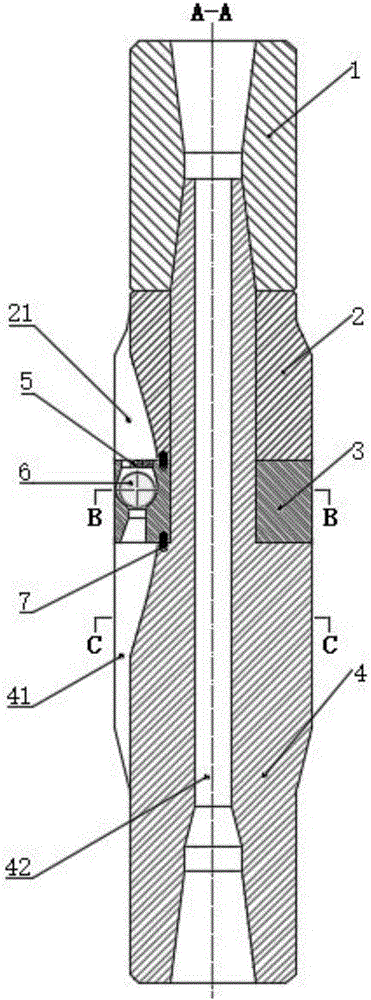

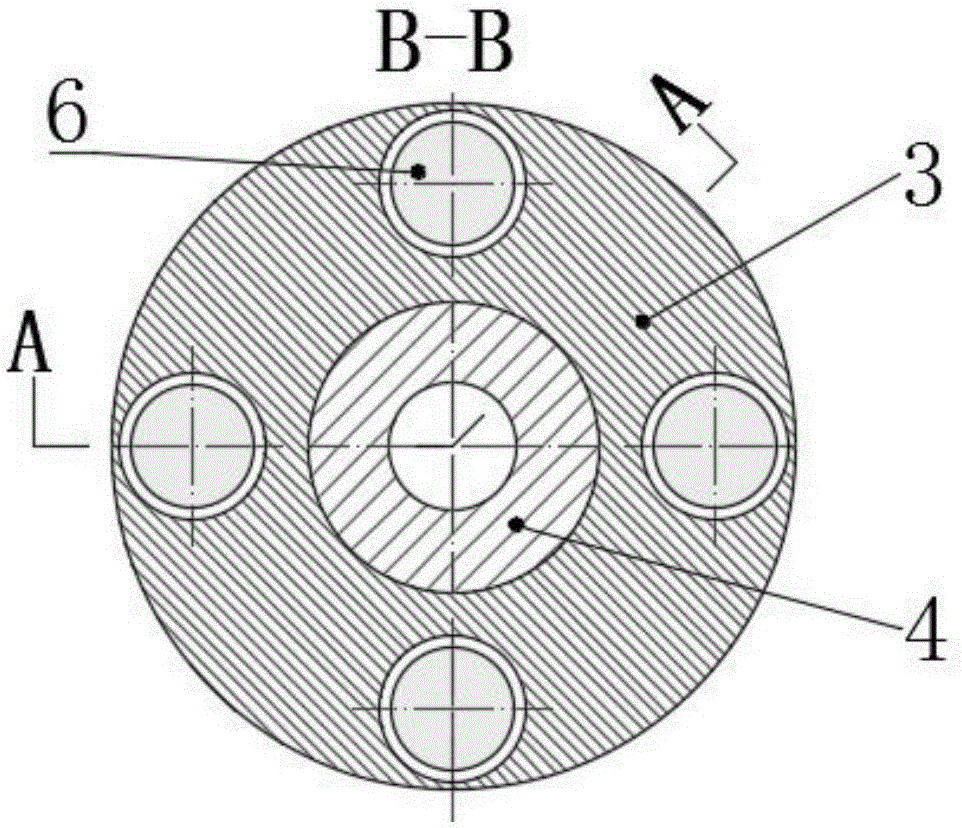

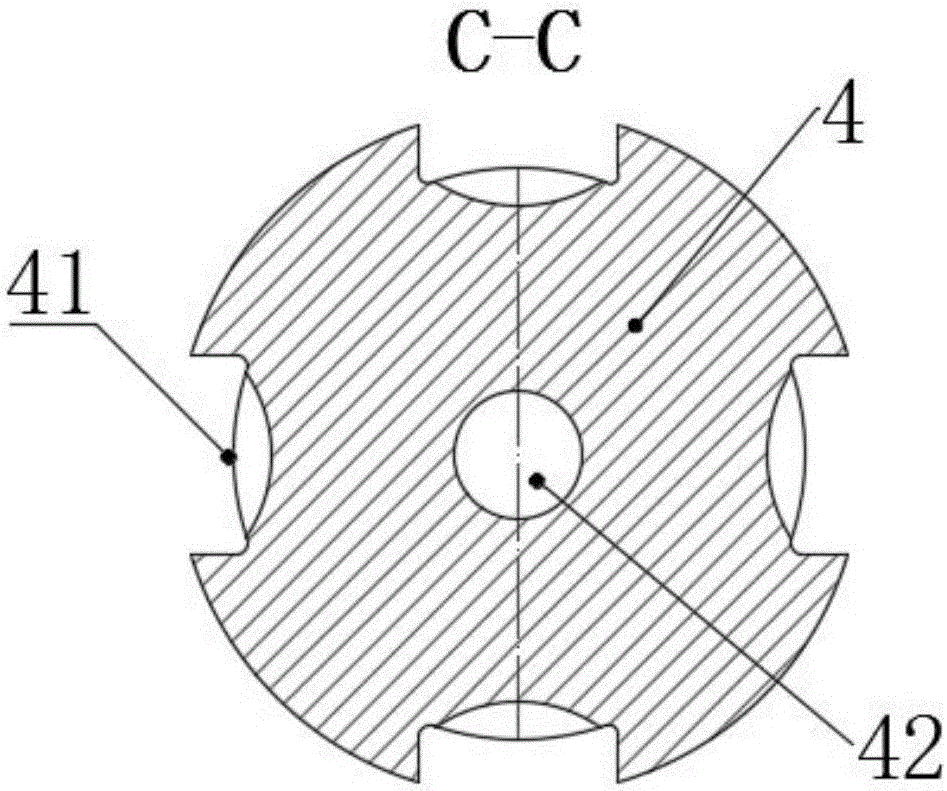

[0019] The main structure of the instantaneous negative pressure underbalanced drilling device described in this embodiment includes an upper joint 1, a diversion compression sleeve 2, an upper diversion compression sleeve flow channel 21, a ball seat body 3, a lower diversion joint 4, The lower guide joint flow channel 41, the lower guide joint central flow channel 42, the ball retainer 5, the ball 6 and the positioning pin 7; the lower joint 4 is provided with a through lower guide joint central flow channel extending along its axis direction. Road 42, the outer side is provided with the lower guide joint flow channel 41 of annular structure and the upper guide compression sleeve flow channel 21; the lower end of the lower joint 4 is provided with a connecting thread for connecting an external drill bit; the lower joint 4 The middle and upper parts are sequentially set with a ball seat body 3, a diversion compression sleeve 2 and an upper joint 1 from bottom to top, and the u...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com