Cylinder-cover-free engine with novel crankshaft-connecting-rod mechanism

A crankshaft connecting rod and engine technology, applied in the direction of machines/engines, combustion engines, mechanical equipment, etc., can solve the problems of insufficient fuel combustion, difficult quality assurance, and inability to work continuously, etc., to achieve increased oxygen, simple structure, and reliable operation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

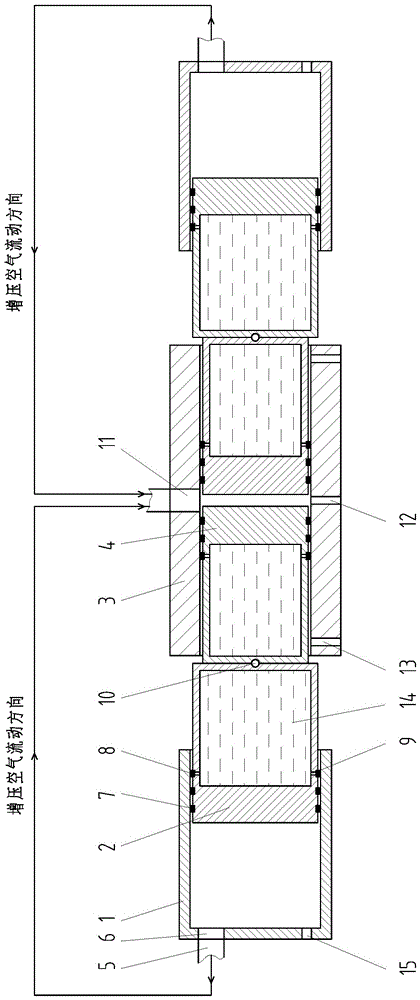

[0028] The present invention will be further described below in conjunction with the accompanying drawings.

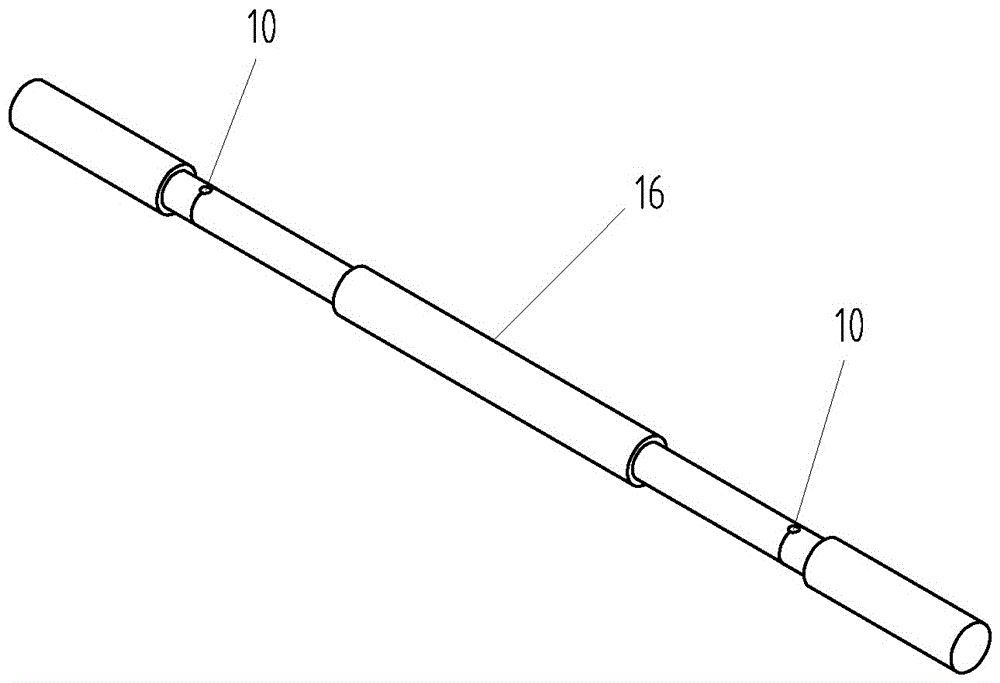

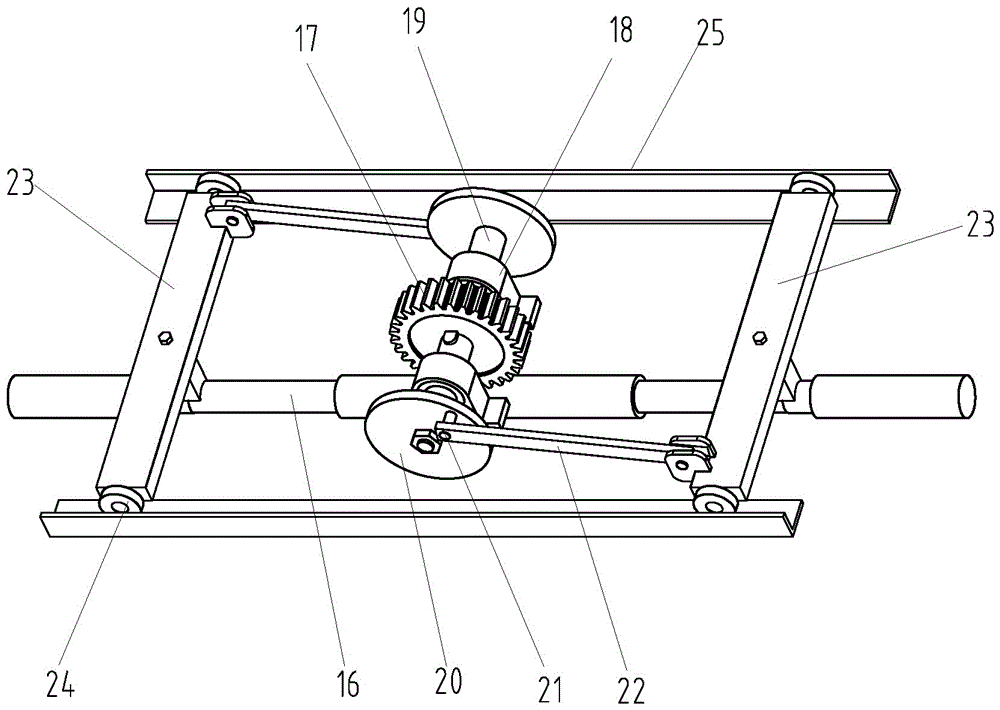

[0029] Such as image 3As shown, the power output unit of the engine of the present invention comprises a novel crankshaft connecting rod mechanism, power output gear 17 and cylinder opposing device 16; Plate 23; the power output gear 17 is fixedly installed in the middle of the straight shaft 19, the centers of the two round wheels 20 are respectively fixedly connected to the two ends of the straight shaft 19, and the two round wheels 20 are provided with protruding outwards at the edge of the disk surface. The eccentric pins 21 of the two eccentric pins 21 are opposite to the positions on the disc surfaces of the two round wheels 20; the two sides of the straight shaft 19 are each provided with a rail-fixing plate 23 parallel to the straight shaft 19, and the eccentricity of the two round wheels 20 Pin shafts 21 are respectively articulated with one end of two conne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com