Multi-layer compounded thermal-contraction rubber sleeve

A multi-layer composite, heat shrinkable technology, applied in the field of plastic products, can solve the problems of product quality decline, restricting industry development, low automation level, etc., to achieve the effect of protecting pipes, ensuring shrinkage rate and tight connection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The embodiments of the present invention will be described in detail below with reference to the accompanying drawings, but the present invention can be implemented in many different ways defined and covered by the claims.

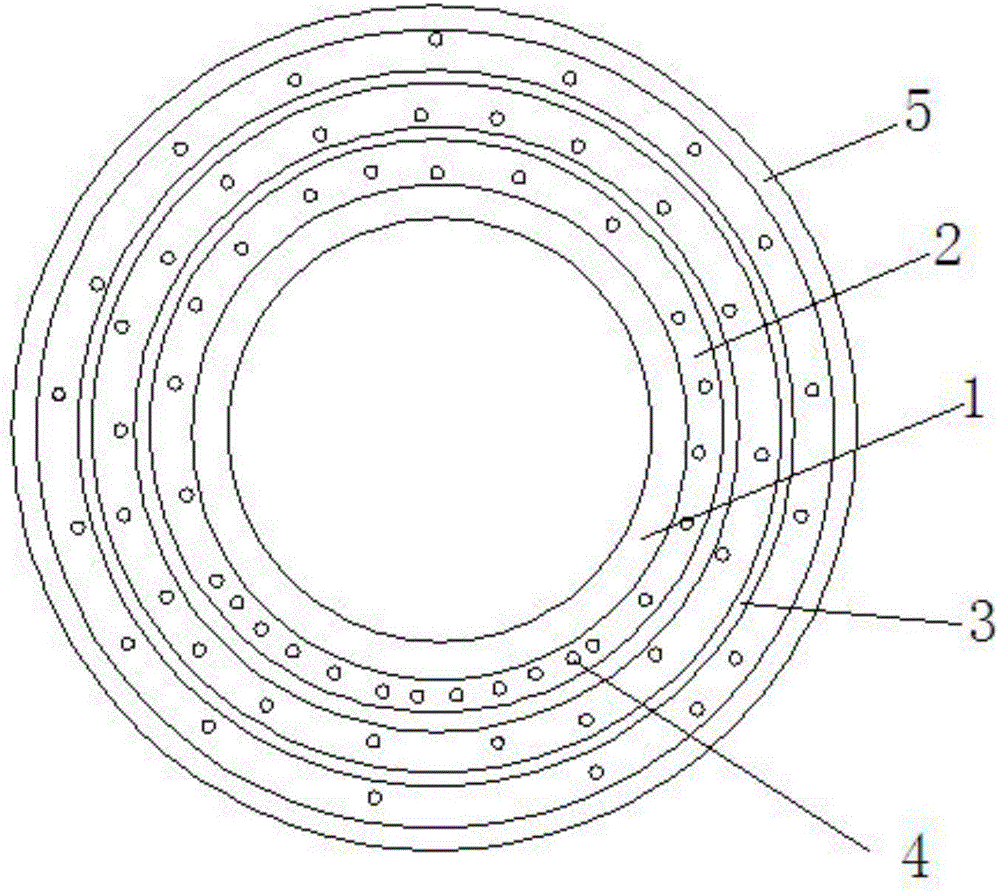

[0013] Such as figure 1 As shown, the present invention discloses a multi-layer composite heat-shrinkable rubber sleeve, which includes a rubber sleeve body whose cross-section is in a ring structure, and the rubber sleeve body includes a melt adhesive layer 1 located on the innermost ring and an outer The base material layer 2, the base material layer 2 has multiple layers, and a melt glue 3 connecting layer is arranged between every two layers of base material layers 2, so that the connection between the multiple layers is tighter, and the base material layer 2 is provided with There are multiple small holes 4, multiple holes 4 and multi-layer compounding, so that the heat-shrinkable rubber sleeve is more closely attached to the pipe after shrinki...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com