High-shrinkage flat acrylic fiber and production method thereof

A technology of acrylic fiber and production method, applied in the field of high-shrinkage flat acrylic fiber and its production, can solve the problems of inability to meet user requirements, the hand feeling of the finished product is not plump, and the variability of acrylic fiber knitting, etc., to achieve strong rigidity, increased softness and hand feel , the effect of good spinnability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

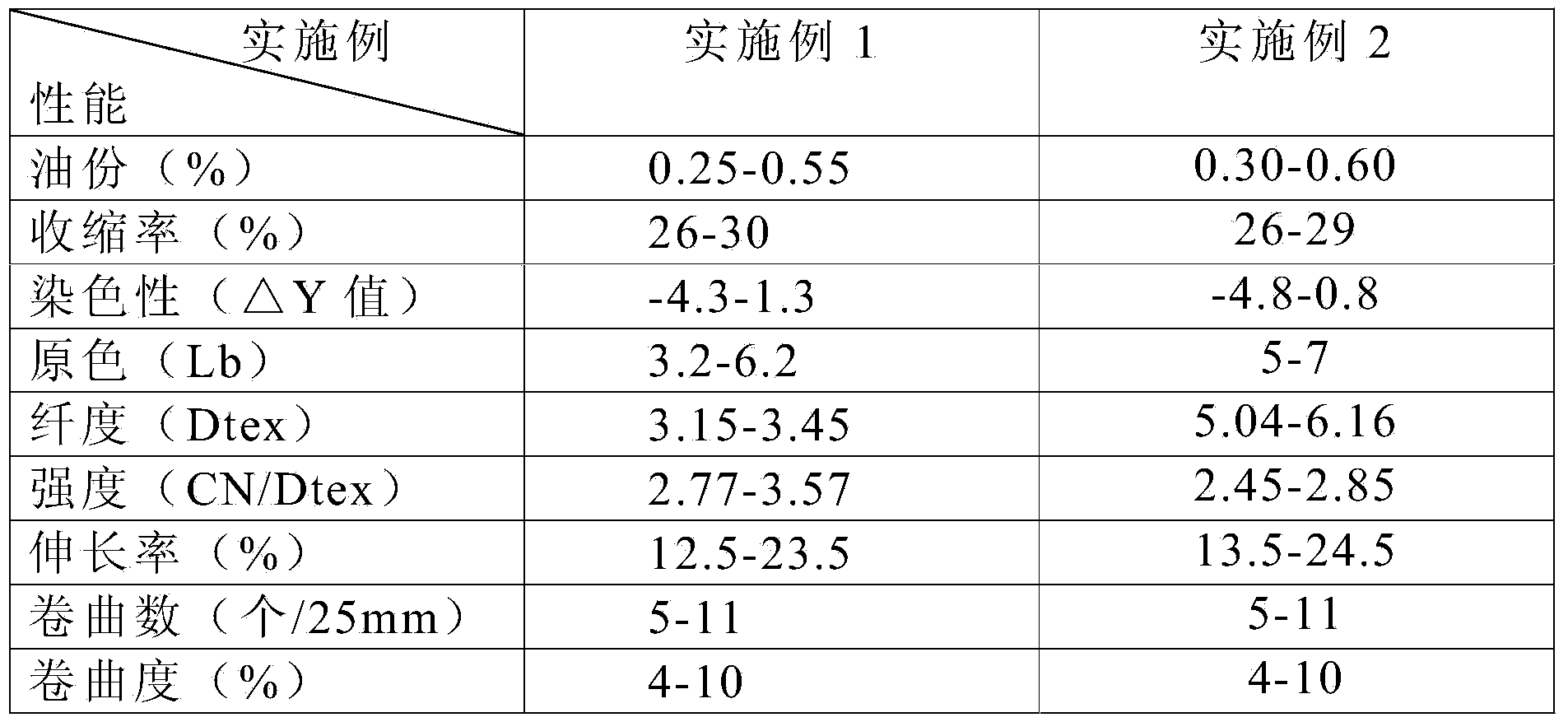

Embodiment 1

[0038] Embodiment 1: Preparation of 3D high shrinkage flat fiber

[0039] Spinning forming: Copolymerize 91-94% of acrylonitrile and 6-9% of vinyl acetate under the catalysis of persulfate and sulfite to make polyacrylonitrile dry powder with a molecular weight of 60,000-100,000. The acrylonitrile dry powder is dissolved in the solvent dimethylacetamide to form a stock solution with a concentration of 20-25%. The stock solution is heated to 82-90°C by a heater, and the heated stock solution is extruded from the rectangular hole of the spinneret. In the coagulation bath, primary fibers are formed by double diffusion; wherein, the temperature of the stock solution when entering the coagulation bath is 80-90°C, the temperature of the coagulation bath is 30-45°C, and the concentration of the solvent dimethylacetamide in the coagulation bath is 30- 50%, the circulation volume is 28-35kL / h. The spinneret is a rectangular plate with a length of 113 mm and a width of 55 mm. The lengt...

Embodiment 2

[0044] Embodiment 2: Preparation of 5D high shrinkage flat fiber

[0045] Spinning forming: Copolymerize 91-94% of acrylonitrile and 6-9% of vinyl acetate under the catalysis of persulfate and sulfite to make polyacrylonitrile dry powder with a molecular weight of 60,000-100,000. The acrylonitrile dry powder is dissolved in the solvent dimethylacetamide to form a stock solution with a concentration of 20-25%. The stock solution is heated to 82-90°C by a heater, and the heated stock solution is extruded from the rectangular hole of the spinneret. In the coagulation bath, primary fibers are formed by double diffusion; wherein, the temperature of the stock solution when entering the coagulation bath is 80-90°C, the temperature of the coagulation bath is 30-45°C, and the concentration of the solvent dimethylacetamide in the coagulation bath is 30- 50%, the circulation volume is 28-35kL / h. The spinneret is a rectangular plate with a length of 113mm and a width of 55mm. The length ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

| shrinkage | aaaaa | aaaaa |

| stretch ratio | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com