Semiconductor assembly pressure testing device and testing equipment

A pressure test and semiconductor technology, which is applied in the field of semiconductor component pressure test equipment and its test equipment, can solve the problems of low production capacity and high gas leakage rate, and achieve the effect of improving the tightness, improving the pressure leakage rate, and increasing the test accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

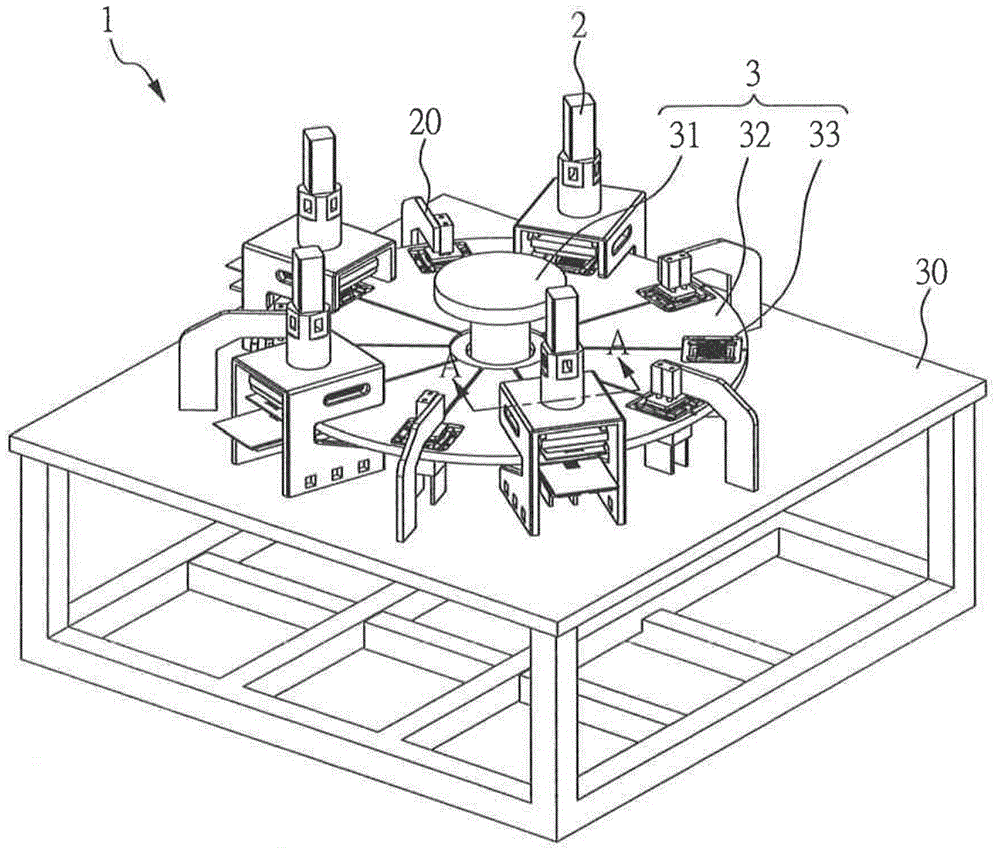

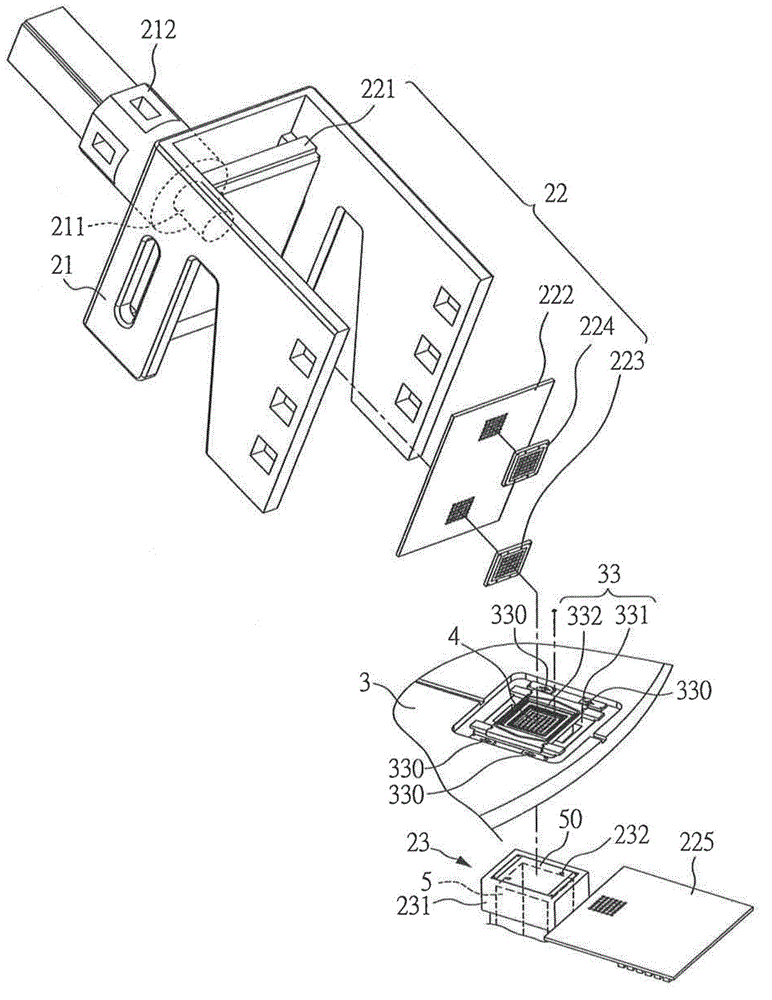

[0030] see figure 1 and figure 2, is a perspective view and an exploded view of a semiconductor component pressure testing device according to a preferred embodiment of the present invention. The figure shows a semiconductor component stress testing device 1, including a plurality of stress testing units 2, a plurality of preheating stations 20 and a turntable unit 3, each preheating station 20 and each stress testing unit 2 are arranged at intervals in a ring, In this embodiment, there are altogether five pressure testing units 2 and five adjacent preheating stations 20 , but the number is not limited thereto. figure 1 A group of pressure test units 2 is specially removed in order to describe some features of the turntable unit 3 conveniently.

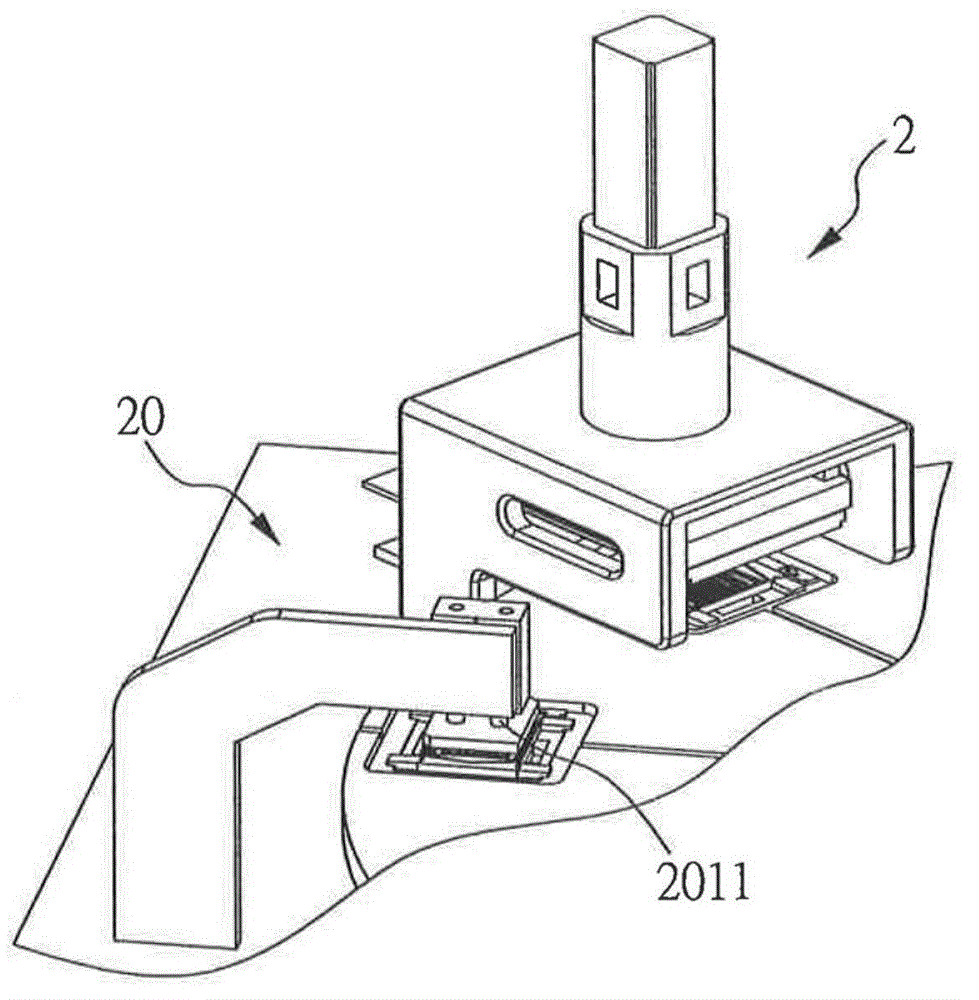

[0031] As shown in the figure, each pressure testing unit 2 includes a support frame 21 , an upper test seat 22 and a lower test seat 23 . The support frame 21 is fixed on a work table 30, and is equipped with a first power unit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com