Ultralow-attenuation and large-effective-area single-mode optical fiber

An effective area, single-mode fiber technology, applied in the field of optical communication, can solve problems such as fiber microbending performance that does not involve fiber dispersion coefficient, complex cross-sectional structure design and manufacturing process, unavoidable doping interface defects, etc., to reduce the interface. Effects of defects, reducing structural relaxation time mismatch, and suppressing fundamental mode cut-off problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] The present invention will be described in detail below in conjunction with specific embodiments.

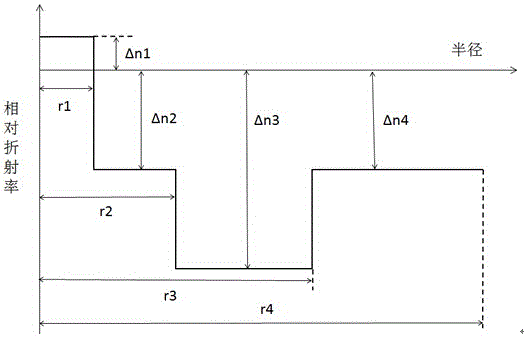

[0045] The optical fiber includes a core layer, an inner cladding layer, a depressed inner cladding layer and an outer cladding layer from the inside to the outside. The core layer is a silica glass layer co-doped with germanium, fluorine and alkali metal, or a silica glass layer co-doped with germanium and alkali metal; the inner cladding closely surrounds the core layer; the sunken inner cladding closely surrounds the inner cladding, composed of fluorine doped two Composed of silica quartz glass; the sunken inner cladding surrounds the outer cladding, and the outer cladding is a fully fluorine-doped silica glass layer; the radius of the outer cladding is 62.5 μm.

[0046] In the embodiment, the optical fiber is processed by wire drawing from an optical fiber preform. The preform mainly includes two parts: an optical fiber core rod and a large sleeve made of hollow synth...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Radius | aaaaa | aaaaa |

| Radius | aaaaa | aaaaa |

| Area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com