A single-mode optical fiber with ultra-low attenuation and large effective area

An effective area, single-mode fiber technology, applied in the field of optical communication, can solve the problems such as fiber microbending performance that does not involve fiber dispersion coefficient, complex cross-sectional structure design and manufacturing process, unavoidable doping interface defects, etc., so as to reduce the interface Effects of defects, reducing structural relaxation time mismatch, and suppressing fundamental mode cut-off problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] The present invention will be described in detail below with reference to specific embodiments.

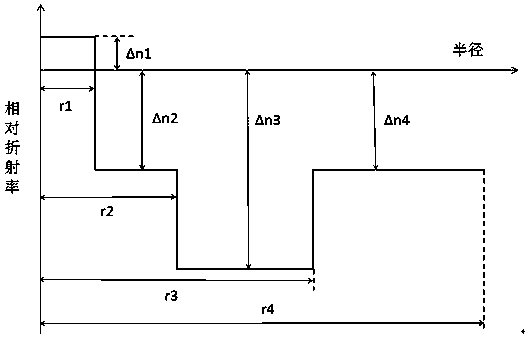

[0045] The optical fiber includes a core layer, an inner cladding layer, a depressed inner cladding layer and an outer cladding layer from the inside to the outside. The core layer is a silica glass layer co-doped with germanium fluorine and alkali metal, or a silica glass layer co-doped with germanium and alkali metal; the inner cladding layer closely surrounds the core layer; It is composed of silica quartz glass; the sunken inner cladding is surrounded by an outer cladding, and the outer cladding is a fully fluorine-doped silica glass layer; the outer cladding radius is 62.5 μm.

[0046] In the embodiment, the optical fiber is formed by drawing an optical fiber preform, and the preform mainly includes two parts: an optical fiber core rod and a large sleeve of hollow synthetic fluorine-doped silica glass, and the optical fiber core rod and the large sleeve are assembled i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com