Electronic nose sampling data pre-calibration method based on response curve differential characteristic

A technology of sampling data and electronic nose, which is applied in the direction of analyzing materials, material inspection products, and analyzing gas mixtures, etc., which can solve the problems of inability to verify sampling data, achieve the effects of accurate classifiers, wide application ranges, and improved reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be described below in conjunction with the accompanying drawings and embodiments.

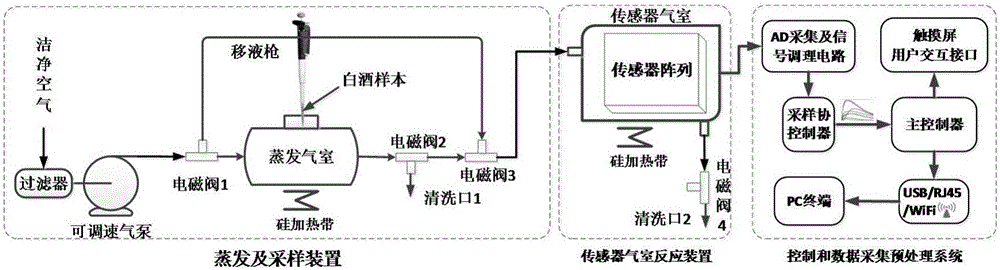

[0030] The electronic nose structure that the present invention relates to is as figure 1 As shown, the electronic nose can not only directly detect gas samples, but also be used to detect liquid samples such as liquor. The electronic nose mainly includes three parts: evaporation and sampling device, sensor air chamber reaction device, and control and data acquisition preprocessing system.

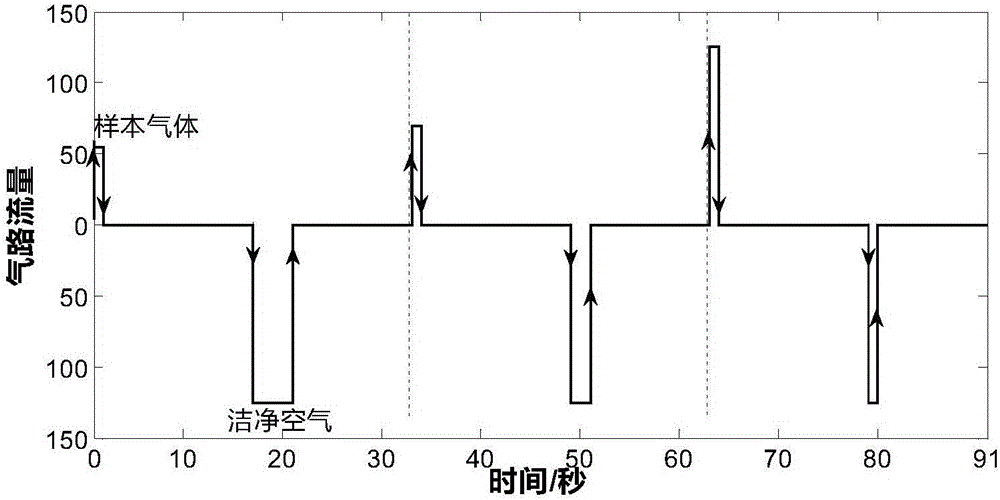

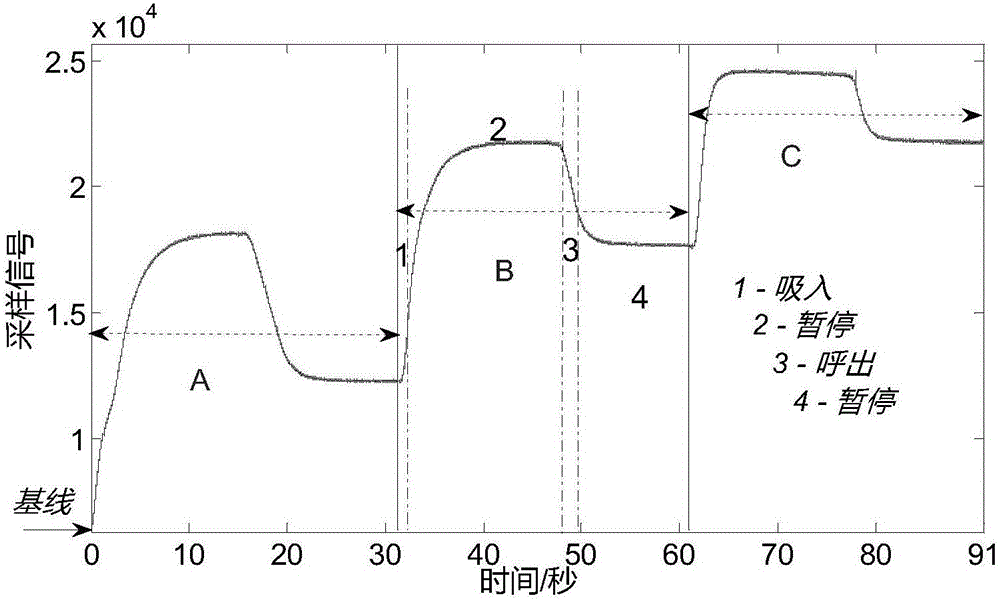

[0031] The electronic nose device of the present invention includes an adjustable-speed air pump, a solenoid valve, an evaporation air chamber, a sensor air chamber, an AD acquisition chip and a main controller. The sampling method involved in the present invention takes the detection of liquor samples as an example, and the main workflow of the electronic nose is as follows: figure 1 As shown, firstly, the liquor sample in the evaporating gas chamber is fully evaporated ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com