System for controlling tube current in mixed way and control method thereof

A hybrid control and control system technology, applied in electrical components, X-ray equipment, etc., can solve the problems of large influence of device differences on circuits, difficulty in meeting cutting-edge requirements, poor scalability and changeability, etc., to achieve strong processing capabilities and real-time performance. , to solve the problem of device aging, the effect of large flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

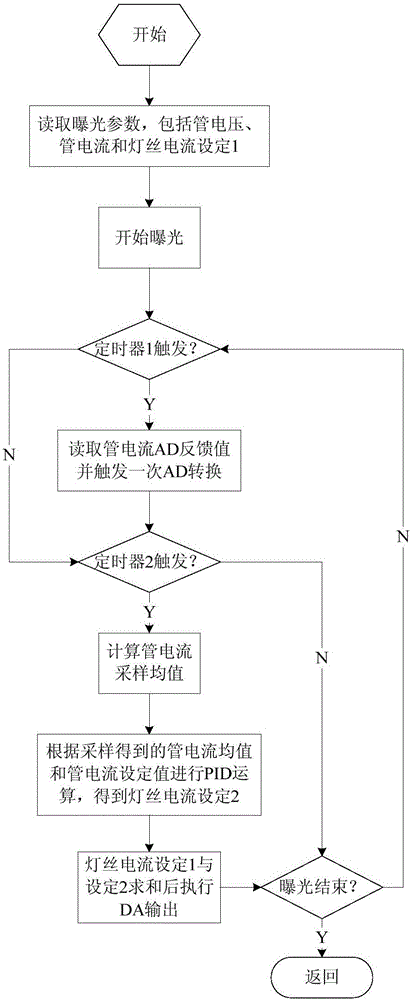

[0031] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

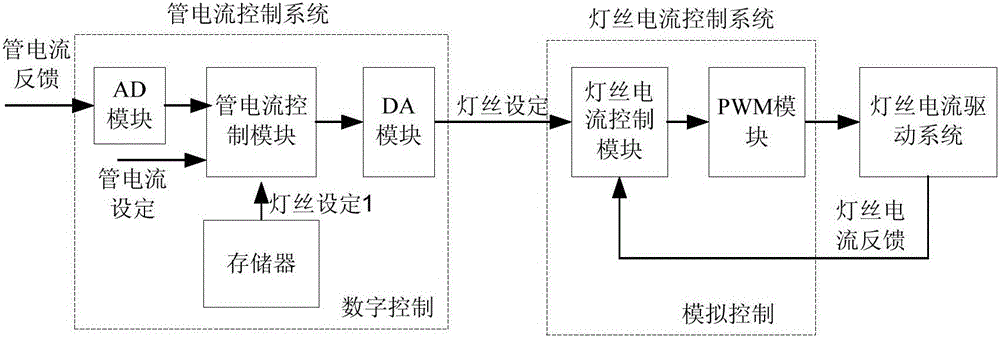

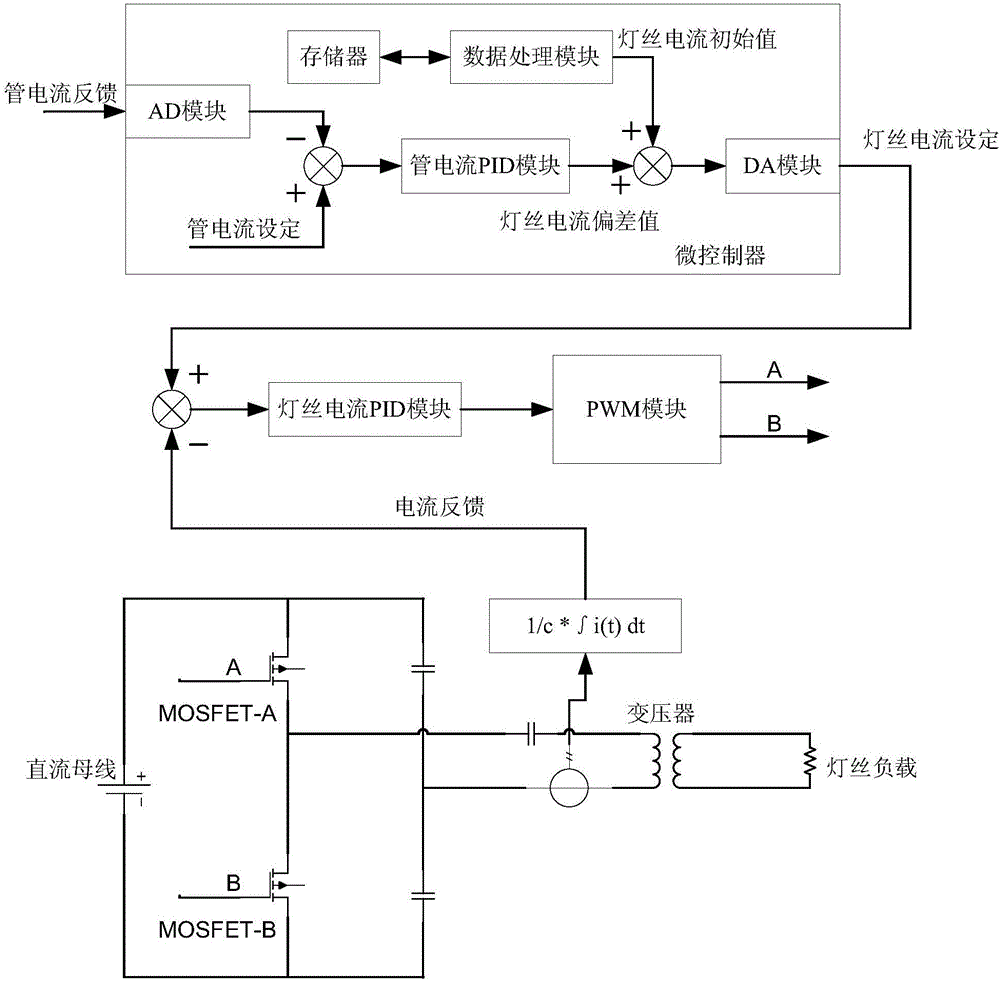

[0032] The invention provides a system for accurately controlling the tube current of an X-ray tube in a mixed manner of digital technology and analog technology, including a control system and a drive system; the control system is a double closed-loop control system, the outer loop is a tube current closed-loop control system, and the inner loop Loop is the filament current closed-loop control system.

[0033] The tube current closed-loop control uses digital technology, with a microcontroller as the core, and cooperates with the system software to realize precise control of the tube current. It samples the tube current in real time, compares it with the tube current setting, and obtains the filament current setting value through calculation. , output to the filament current closed-loop control system.

[0034] The tube current closed-loop c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com