Manufacturing process for high-thermal-conductivity graphite film

A high thermal conductivity graphite, manufacturing process technology, applied in cooling/ventilation/heating transformation, modification by conduction heat transfer, application, etc., can solve the problem of uneven quality and performance of polyimide film products, affecting heat dissipation and double-sided film heat dissipation performance, product heat dissipation performance instability and other issues, to avoid volume shrinkage, improve thermal conductivity, improve density and crystallinity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

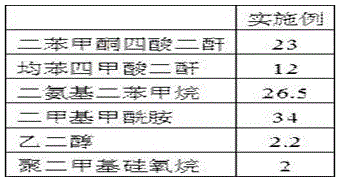

[0018] Embodiment: A kind of manufacturing process that is used for high thermal conductivity graphite film, described high thermal conductivity graphite film is bonded between radiator and heating component, and described high thermal conductivity graphite film comprises light peeling type PET film and heavy peeling type PET film , the first thermally conductive adhesive layer, the graphite layer and the second thermally conductive adhesive layer are sequentially arranged between the lightly peelable PET film and the heavy peelable PET film; the graphite layer is obtained by the following process, which includes the following step:

[0019] Step 1. Raise the polyimide film from room temperature to 250°C at a speed of 4~6°C / min, keep it for 0.9~1.1 hours, then raise it to 400°C at a speed of 2.5~3.5°C / min, keep it for 1 hour and then lower it. to room temperature;

[0020] Step 2, on the upper and lower surfaces of the polyimide film through step 1, a layer of graphite modifi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com