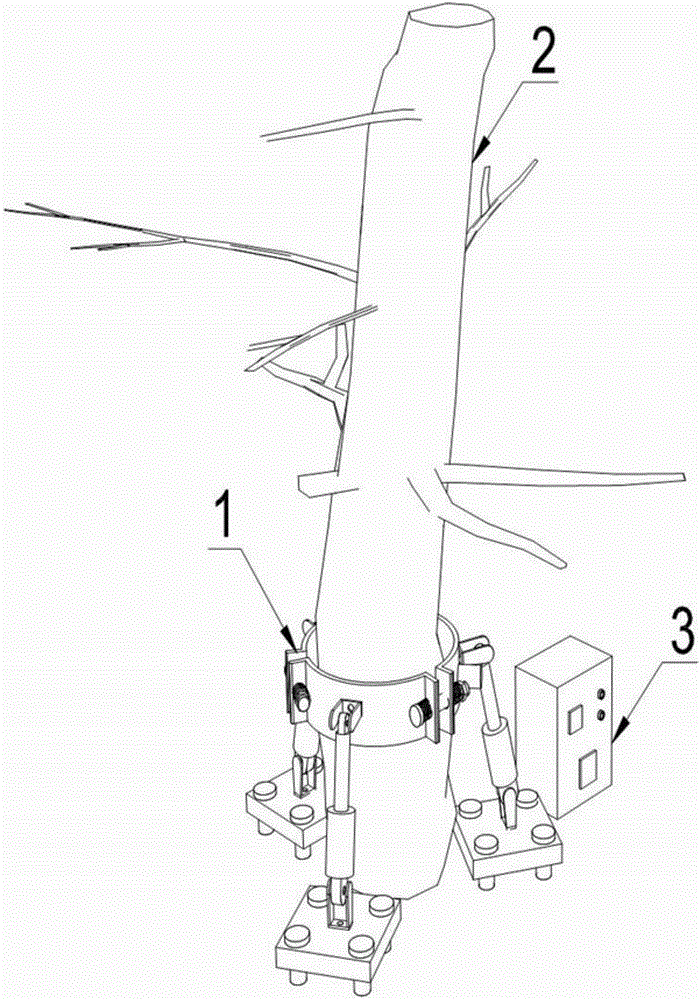

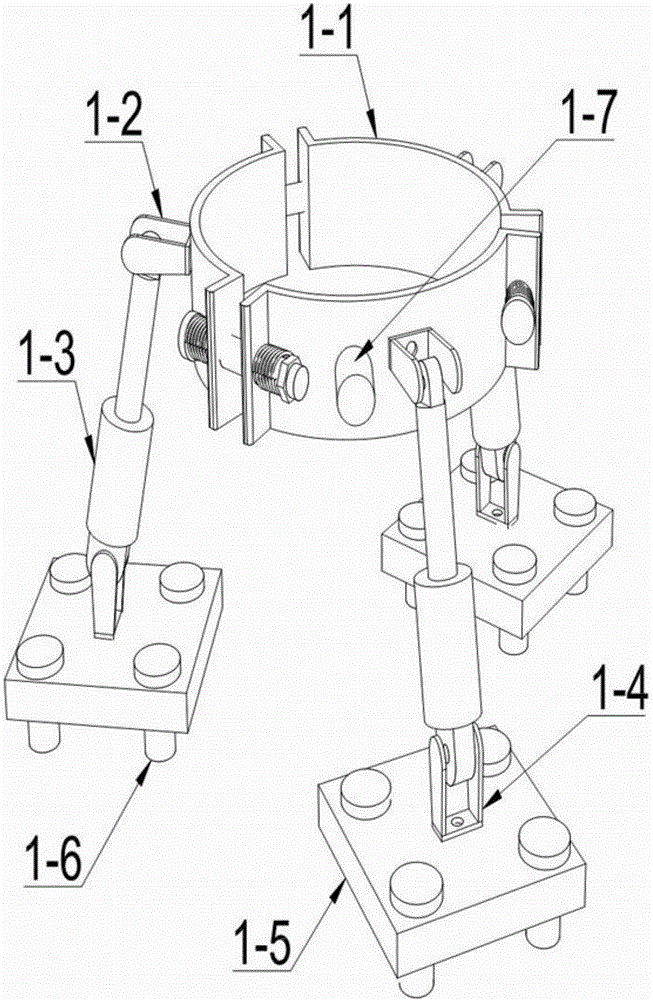

Straightening device for preventing garden trees from obliquely growing and work method thereof

A technology for trees and gardens, which is applied in the field of straightening devices to prevent garden trees from growing and skewing, and can solve the problems of high labor intensity, low efficiency, and low service life, and achieve reasonable and compact structure design, convenient and fast use, and firm structure reasonable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

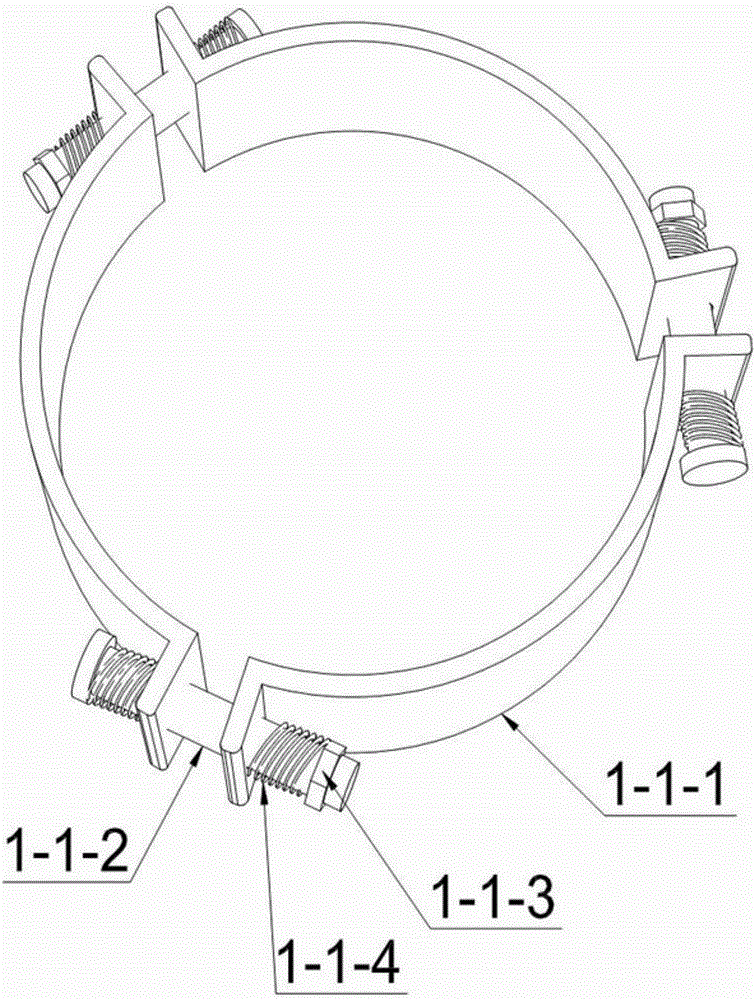

[0051] The clamp hoop 1-1-1 of the present invention is manufactured according to the following steps, and is counted in parts by weight:

[0052] Step 1: Add 533 parts of ultra-pure water with a conductivity of 0.43μS / cm into the reaction kettle, start the agitator in the reaction kettle at a speed of 93rpm, start the heating pump, and raise the temperature in the reaction kettle to 63°C; add in sequence 63 parts of α-(hydroxymethyl)phenylacetic acid N-isopropyl nortropine ester, 83 parts of N-(2-isopropionic acid)-o-hydroxybenzoyl hydrazone, 133 parts of diisopropyl phthalate part, stir until completely dissolved, adjust the pH value to 3.3, adjust the speed of the agitator to 133rpm, the temperature is 93°C, and the esterification reaction is 33 hours;

[0053] Step 3: Take 83 parts of 4-hydroxy-3-hydroxymethyl-α-bromoacetophenone diacetate, α-cyano-m-phenoxymethyl-α-isopropyl-p-chloro 73 parts of ethyl phenyl esters are pulverized, and the particle size of the powder is 3...

Embodiment 2

[0058] The clamp hoop 1-1-1 of the present invention is manufactured according to the following steps, and is counted in parts by weight:

[0059] Step 1: Add 1303 parts of ultrapure water with a conductivity of 0.73μS / cm into the reactor, start the stirrer in the reactor at a speed of 333rpm, start the heating pump, and raise the temperature in the reactor to 83°C; add in order 143 parts of N-isopropylnortropine α-(hydroxymethyl)phenylacetic acid, 143 parts of N-(2-isopropionic acid)-o-hydroxybenzoyl hydrazone, 353 parts of diisopropyl phthalate part, stir until completely dissolved, adjust the pH value to 7.3, adjust the speed of the agitator to 353rpm, the temperature is 163°C, and the esterification reaction is 53 hours;

[0060] Step 3: Take 193 parts of 4-hydroxy-3-hydroxymethyl-α-bromoacetophenone diacetate, α-cyano-m-phenoxymethyl-α-isopropyl-p-chloro 153 parts of ethyl phenyl esters were pulverized, and the particle size of the powder was 533 meshes; 343 parts of N-(3-...

Embodiment 3

[0065] The clamp hoop 1-1-1 of the present invention is manufactured according to the following steps, and is counted in parts by weight:

[0066] Step 1: Add 903 parts of ultrapure water with a conductivity of 0.63μS / cm into the reactor, start the stirrer in the reactor at a speed of 133rpm, start the heating pump, and raise the temperature in the reactor to 73°C; add in order 123 parts of N-isopropylnortropine α-(hydroxymethyl)phenylacetic acid, 113 parts of N-(2-isopropionic acid)-o-hydroxybenzoyl hydrazone, 253 parts of diisopropyl phthalate part, stir until completely dissolved, adjust the pH value to 6.3, adjust the speed of the agitator to 253rpm, the temperature is 113°C, and the esterification reaction takes 43 hours;

[0067] Step 3: Take 133 parts of 4-hydroxy-3-hydroxymethyl-α-bromoacetophenone diacetate, α-cyano-m-phenoxymethyl-α-isopropyl-p-chloro 103 parts of ethyl phenyl esters are pulverized, and the particle size of the powder is 433 meshes; 243 parts of N-(...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Conductance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com