Submerged arc welding flux for steam temperature ultra-supercritical thermal power unit steel and preparation method thereof

An ultra-supercritical, thermal power unit technology, used in welding equipment, manufacturing tools, welding media, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] SiO 2 8kg, MgO 34kg, Al 2 o 3 15kg, CaF 2 36kg, CaO 3kg, ZrO 2 3kg, Re 2 o 3 Put 1kg of powder in a mixer, stir and mix evenly, add 18.0kg of sodium water glass to mix and granulate, then bake at 150°C, sinter at 700°C, and sieve to obtain the flux product.

[0031] The flux is matched with welding wire (the components of the welding wire are: C 0.106, Mn 0.80, Si 0.20, S0.005, P 0.005, Cr 8.91, Co 2.85, W 2.95, V 0.22, Nb 0.071, N 0.010, B 0.008, Cu 0.90, Ce 0.08, Nd 0.061, Ni 0.030, the balance is Fe and impurities) for submerged arc welding experiments on 20mm thick G115 steel plates. Excellent welding process performance, good slag removal, stable arc, beautiful weld surface, regular weld edges, no undercut, pores, cracks and other defects.

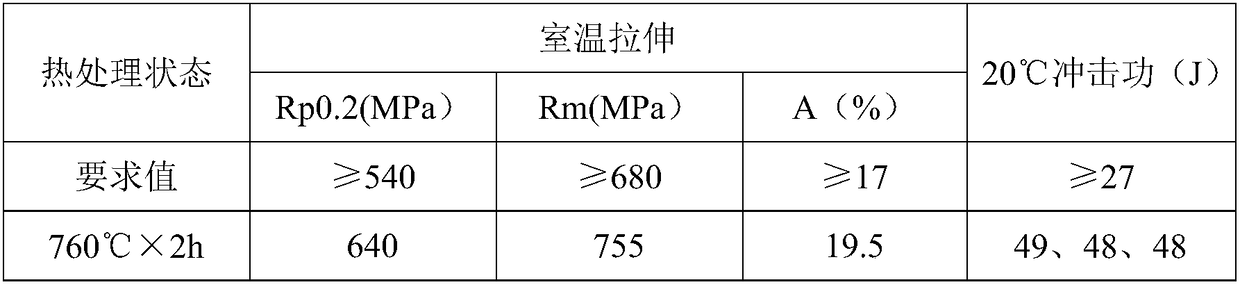

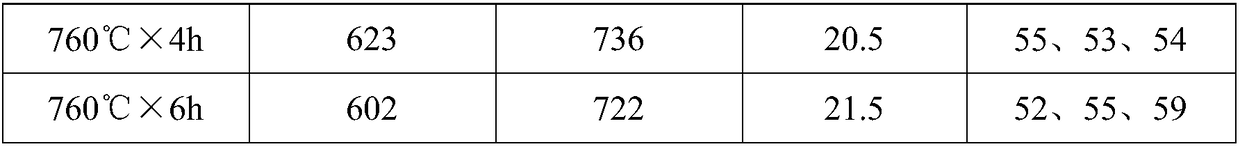

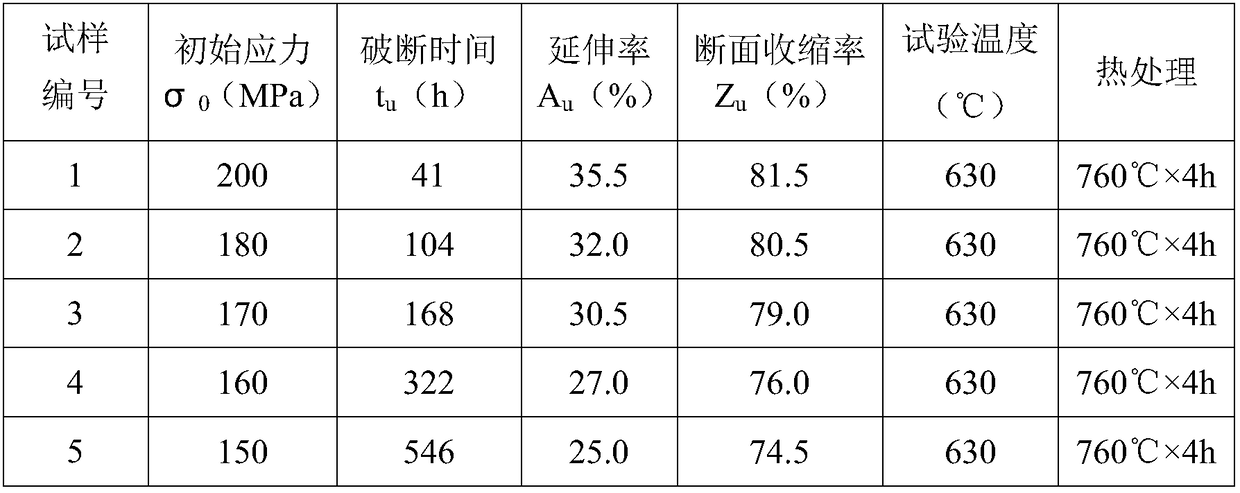

[0032]The flux and welding wire prepared in Example 1 were subjected to a submerged arc welding test, and the chemical composition of the deposited metal was: C: 0.086wt%, Mn: 0.61wt%, Si: 0.26wt%, S: 0.004wt%, P: 0....

Embodiment 2

[0042] SiO 2 6kg, MgO 36kg, Al 2 o 3 16kg, CaF 2 39kg, CaO 2kg, ZrO 2 1.5kg, Re 2 o 3 Put 0.5kg of powder in a mixer, stir and mix evenly, add 18.5kg of sodium water glass to mix and granulate, then bake at 150°C, sinter at 700°C, and sieve to obtain the flux product.

[0043] The flux is matched with welding wire (the components of the welding wire are: C 0.106, Mn 0.80, Si 0.20, S0.005, P 0.005, Cr 8.91, Co 2.85, W 2.95, V 0.22, Nb 0.071, N 0.010, B 0.008, Cu 0.90, Ce 0.08, Nd 0.061, Ni 0.030, the balance is Fe and impurities) for submerged arc welding experiments on 20mm thick G115 steel plates. Excellent welding process performance, good slag removal, stable arc, beautiful weld surface, regular weld edges, no undercut, pores, cracks and other defects.

[0044] The flux and welding wire prepared in Example 2 were subjected to a submerged arc welding test, and the chemical composition of the deposited metal was: C: 0.088wt%, Mn: 0.62wt%, Si: 0.24wt%, S: 0.004wt%, ...

Embodiment 3

[0053] SiO 2 5kg, MgO 37kg, Al 2 o 3 17kg, CaF 2 37kg, CaO 2kg, ZrO 2 1kg, Re 2 o 3 Put 1kg of powder in a mixer, stir and mix evenly, add 19.0kg of sodium water glass to mix and granulate, then bake at 150°C, sinter at 700°C, and sieve to obtain the flux product.

[0054] The flux is matched with welding wire (the components of the welding wire are: C 0.106, Mn 0.80, Si 0.20, S0.005, P 0.005, Cr 8.91, Co 2.85, W 2.95, V 0.22, Nb 0.071, N 0.010, B 0.008, Cu 0.90, Ce 0.08, Nd 0.061, Ni 0.030, the balance is Fe and impurities) for submerged arc welding experiments on 20mm thick G115 steel plates. Excellent welding process performance, good slag removal, stable arc, beautiful weld surface, regular weld edges, no undercut, pores, cracks and other defects.

[0055] The flux and welding wire prepared in Example 3 were subjected to a submerged arc welding test, and the chemical composition of the deposited metal was: C: 0.091wt%, Mn: 0.63wt%, Si: 0.25wt%, S: 0.005wt%, P: 0...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com