Processing method for four-piece unequal-diameter bearing body of large hydroelectric generating set

A technology of hydroelectric unit and processing method, which is applied in the field of radial bearing body processing, can solve the problems of long production cycle and high scrap rate, achieve high processing precision, significant effect, reduce processing workload and the effect of defective product risk

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

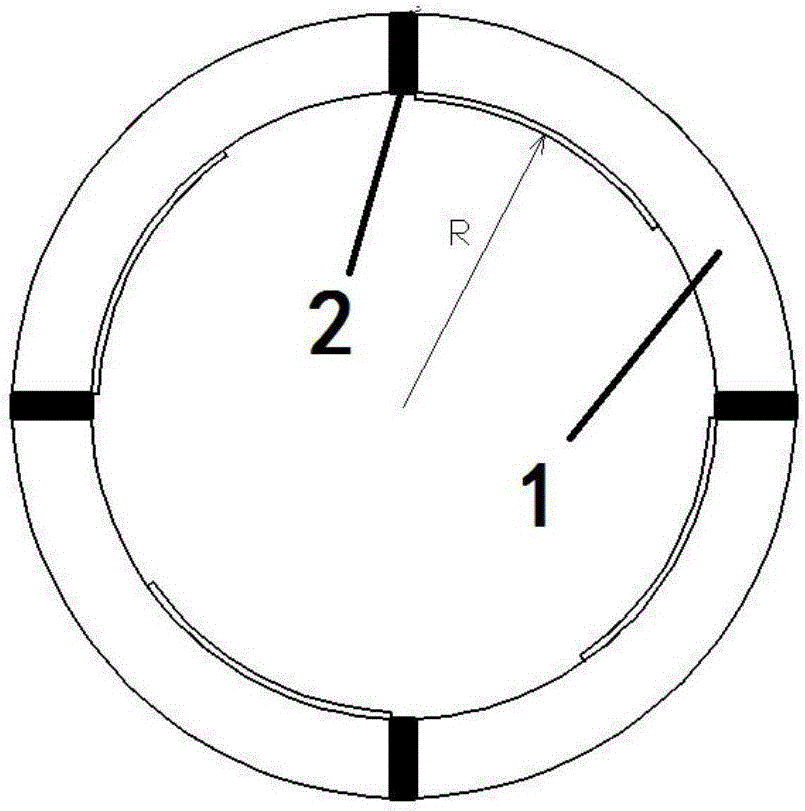

[0070]Taking the four-lobe bearing body of a certain large-scale hydropower unit as an example to illustrate the process of applying the present invention to process: the weight of the bearing body is 7770Kg, the outer diameter is φ2950mm, the positive zero-degree orientation of the unequal-diameter bearing body is the major diameter, and the 45° orientation is the minor diameter. Adopt the present invention to process, process is as follows:

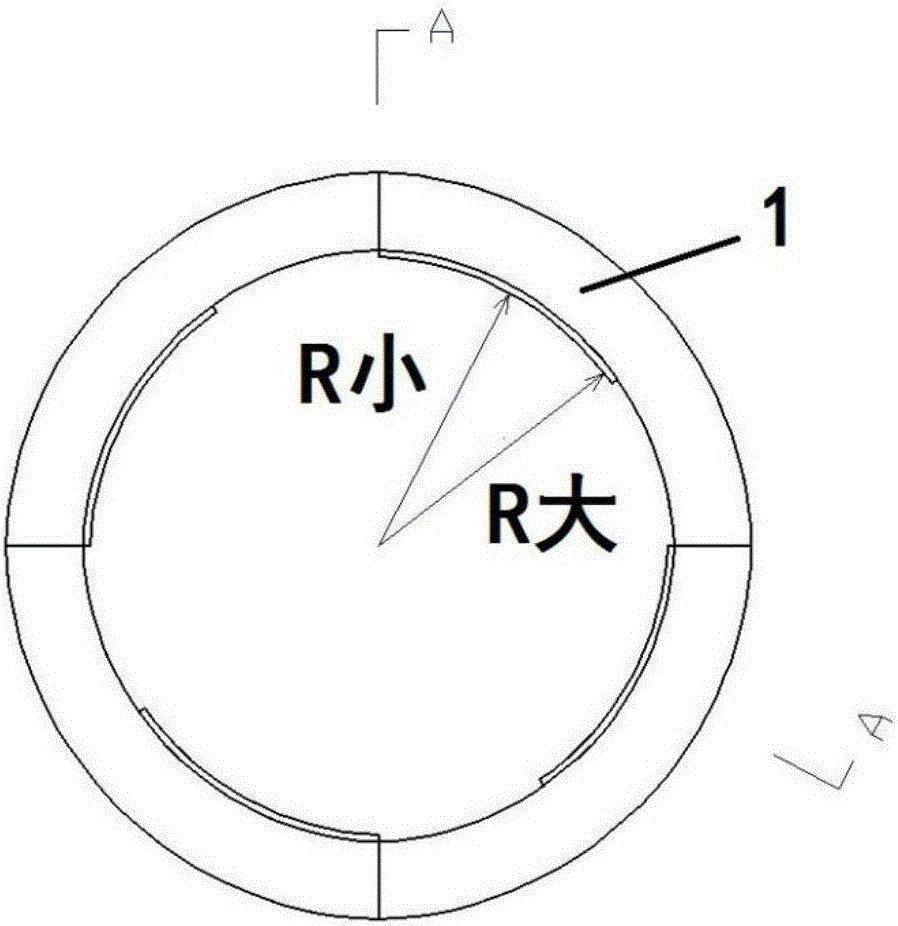

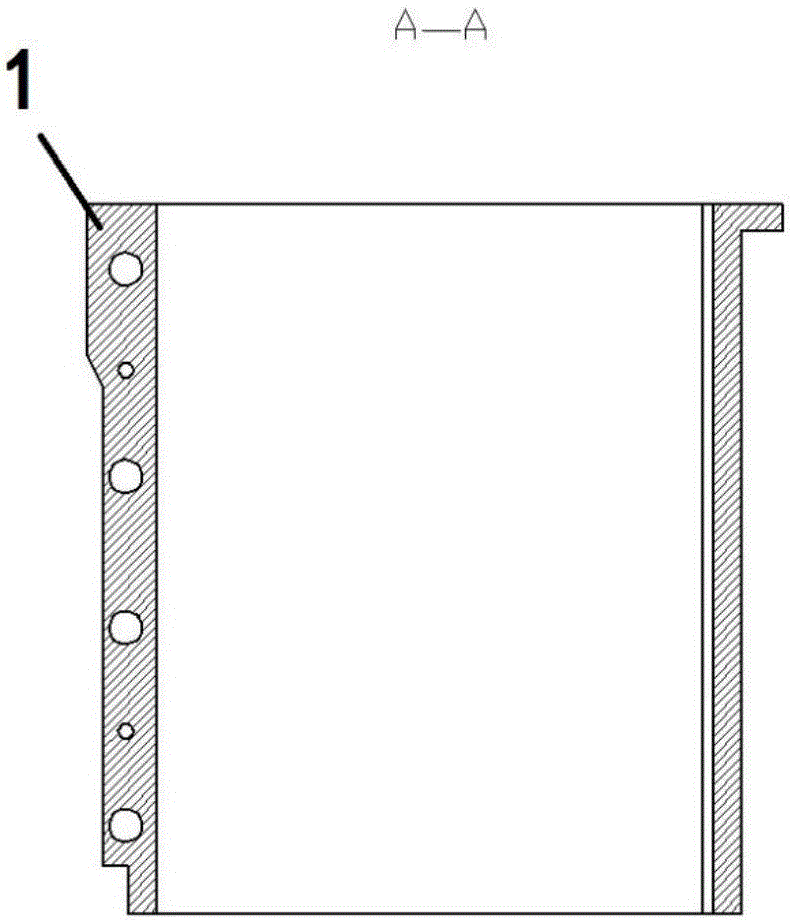

[0071] 1) The first scratch inspection, such as figure 1 As shown, check the machining allowance of each single lobe plane and circumference of the bearing body 1, and mark the flat line, round line, and closing hole line;

[0072] 2) Process the joint surface, refer to the marking inspection line, and according to the technical requirements, mill the joint surface of the four petals, and bore the joint surface to close the hole;

[0073] 3) For the first combination, combine the bearing body 1 according to the flat line and the round ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com