Simple three-claw centering clamp for steel pipe machining

A centering fixture, a simple technology, applied in the direction of manufacturing tools, metal processing equipment, metal processing machinery parts, etc., can solve the problems of high cost, high protection and maintenance requirements, complicated operation, etc., to achieve low production cost, simple structure, Simple operation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further explained below in conjunction with the drawings:

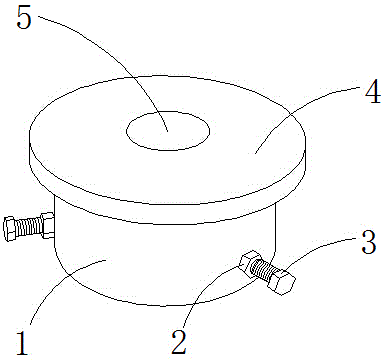

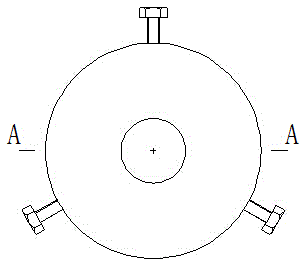

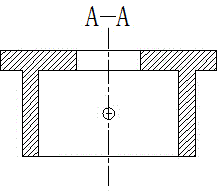

[0016] Such as Figure 1-3 As shown, a simple three-jaw centering fixture for steel pipe processing includes a cylindrical steel pipe 1. Three fixing nuts 2 are uniformly distributed on the outer surface of the cylindrical steel pipe 1 on the same circumference. The fixing nuts 2 are respectively provided with adjusting bolts 3. A cylindrical clamping disc 4 is provided at one end of the cylindrical steel pipe 1, and a central hole 5 communicating with the interior of the cylindrical steel pipe 1 is opened in the center of the cylindrical clamping disc 4.

[0017] Such as Figure 1-3 As shown, a simple three-jaw centering fixture for steel pipe processing, the fixing nut 2 is welded to the outer surface of the cylindrical steel pipe 1; the cylindrical clamping plate 4 and the cylindrical steel pipe 1 are fixed by welding, and the cylindrical clamping plate 4 It is on the same axis as ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com