Extruding forming device for processing system of rubber products

A processing system and molding device technology, which is applied in the extrusion molding device field of the rubber product processing system, can solve the problems that waste water cannot be discharged in time, affects product quality, and has no drainage function, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

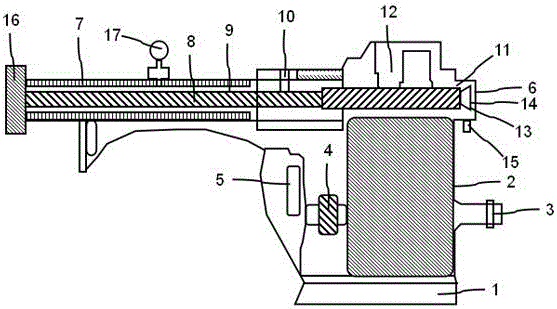

[0017] This embodiment: as figure 1 As shown, an extrusion molding device of a rubber product processing system includes a machine base 1, the machine base 1 is supported on a molding machine chassis 2, and the side end of the molding machine chassis 2 is axially equipped with a main shaft motor 3, and the main shaft The main shaft protruding from the motor 3 is axially connected to the transmission device 5 through the coupling 4. The upper part of the molding machine chassis 2 is axially provided with a barrel 6 that is sleeved on the outer peripheral surface of the molding cavity, and the inner circumference of the cavity at the top of the molding cavity The surface is sleeved with a water jacket 7, the center of the molding cavity is axially provided with a screw 8, the outer peripheral surface of the screw 8 is sleeved with a bushing 9, and the end of the molding cavity is provided with a feed port 10 radially arranged through the molding cavity. The end of the screw rod ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com