Laminating device and laminating method

A lamination device and pressure device technology, applied in the direction of lamination devices, lamination, chemical instruments and methods, etc., can solve the problems of reducing product competitiveness and increasing production costs, so as to improve product competitiveness, speed up stability and save energy Effects on production cost and time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

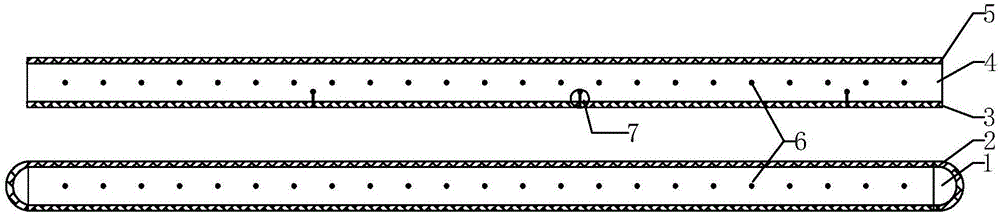

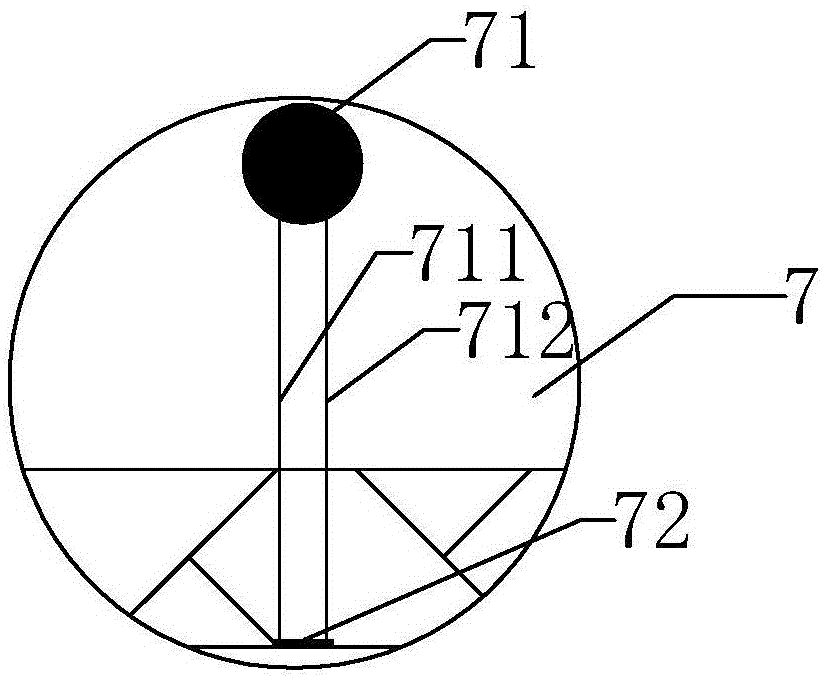

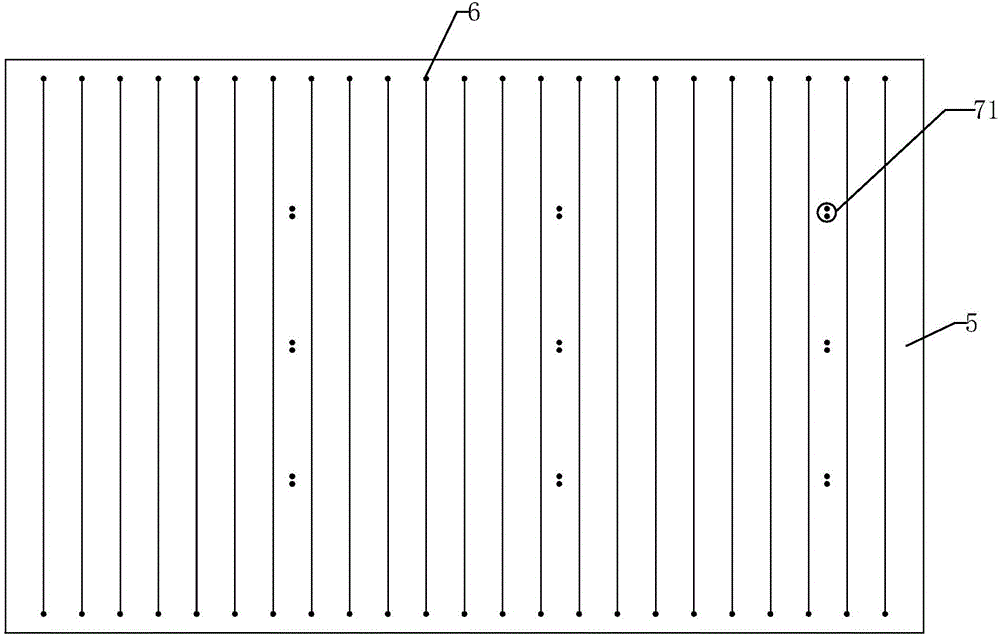

[0026] like figure 1 As shown, it is a lamination device of the present invention, including a lower chamber 1 of a laminator, an upper chamber 4 of a laminator, a vacuum device and a pressure device (not shown), and the lower chamber of the laminator 1 and the upper chamber 4 of the laminator are respectively equipped with a heating device 6, between the lower chamber 1 of the laminator and the upper chamber 4 of the laminator is used for laying thin film battery components to be laminated, and the vacuum device is used for laminating Vacuuming in the press, the pressure device is used to apply force to the upper chamber 4 of the laminator to move toward the lower chamber 1 of the laminator to laminate the thin film battery assembly to be laminated, the upper chamber of the laminator The chamber 4 is also provided with a current applying device 7, the input end of the current applying device 7 is used to connect an external constant current power supply, and the output end is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com